Lecture Notes

advertisement

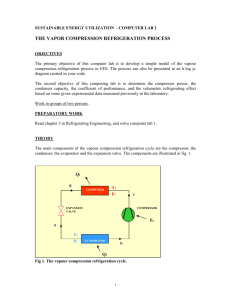

2103393 Lecture Notes 2103393 ME Lab Non ME, Section 4 Second Semester, Academic Year 2554 Department of Mechanical Engineering Chulalongkorn University 1 Introduction 2103393 ME Lab Non ME Section 4 Dr Kuntinee Maneeratana (KMN) 905/Eng4 Topic Evaluation Report 401 Flow through a Venturi 406 Refrigeration 405 Air compressor 2 2 Overall Objectives Introduction to ME tests Experiments For discovery Development Testing Experiments for Quality Control & Product Testing 3 3 Evaluation During experiments Lab Instructor Graph of result summary Submit to KMN by the end of each lab 15% Full group report (1 week later) 85% Equipment testing technical report Submit to supervisors (assume to know engineering fundamentals)) 4 4 Evaluation: Report Abstract Introduction Theory Equipment & procedures Results Discussion Conclusions Appendix Appendices Work declaration by each member Check list 10 5 5 15 25 10 5 10 No more than 7 pages, excluding appendices 5 5 Report: Guideline & Check List MIT Writing Cooperative Technical Report Checklist MIT Report Writing Guidelines 6 6 Report: Equipment & Instruments Equipment Rough specification Instruments Measured quantity (Temperature T1) Range (10 – 50 °C) Resolution (1 °C) C) 7 7 401 FLOW THROUGH A VENTURI 2103393 ME Lab Non ME, Section 4 & 7 Second Semester, Academic Year 2553 Department of Mechanical Engineering Chulalongkorn University 8 Theory: Flow Meters Coriolis Excitation force causes the tube to twist due to coriolis acceleration 9 9 Theory: Flow Meters Magnetic Changes of induced voltage of the conductive fluid 10 10 Theory: Flow Meters Positive displacement Rotating impeller Nutating disc Rotating valve Oscillating piston Oval gear Rotating lobe Birotor 11 11 Theory: Flow Meters … Target Measuring drag forces on the target 12 12 Theory: Flow Meters Differential pressure Flow nozzle Orifice Venturi 13 13 Theory: Pressure Differences Continuity eqn Bernoulli eqn 1 2 , z1 z2 , 1A1u1 2 A2u2 1 m 2 1 1 P1 1u12 1gz1 P2 2u22 2gz2 2 2 1 1 1 A2 2 2 2 2 P1 P2 2u2 1u1 2u2 1 ( ) 2 2 2 A1 Flow rate A2 2 Q A2u2 A2 1 ( ) A1 Actural flow A2 2 Q Cd A2 1 ( ) A1 1/ 2 1/ 2 1/ 2 2 (P1 P2 ) 1/ 2 2 (P1 P2 ) 14 14 Theory: Q – P Relationship P1 P2 g (H1 H2 ) Q Cd A2 2g 1 (D 2 / D1 ) 4 1/ 2 H1 H2 y mx c 15 15 Test Rig 16 16 Objectives Official To understand a method of flow measurements To obtain the value of Cd for a venturi Technical Report Calibrate the meter What is wanted from the report Determine Cd Range of flow rate that you can confidently use the Cd to measure flow rate. 17 17 406 REFRIGERATION 2103393 ME Lab Non ME, Section 4 & 7 Second Semester, Academic Year 2553 Department of Mechanical Engineering Chulalongkorn University 18 Presentation Trane Powerpoint Refrigeration cycle Refrigeration components 19 19 Theory: Cycle C discharge line condenser liquid line expansion device compresso r B A suction line D evaporator 20 20 Theory: Status high hi h T, T high hi h P Saturated/subcool liquid high T, high P superheat vapour condenser d presssure G expansion p device low T, T low P liquid+vapour A F D E 121..5°F 121 [49 49..7°C] evaporator 41..2°F 41 [5.1°C] compressor B C low T, low P p Saturated/superheat vapour enthalpy 21 21 Theory: Formula Energy eqn v2 gz h Q W const 2 kinetic potential enthalpy heat work const v fluid fl id velocity elocit z altitude h enthalpy U PV Q heat entering the system W work leaving the system 22 22 Theory: Formula Compression process 1 2 Heat Q0 ((Isotropic) p ) Work W h1 h2 ( ve work entering) Condensation process 2 3 Heat Q h3 h2 Work W 0 ( ve heat out) Expansion process 3 4, h3 h4 Heat Q0 Work W 0 Evaporation process 4 1 H t Heat Q h1 h4 Work W 0 ( fi (refrigerating ti effect) ff t) 23 23 Theory: Formula COP refrigerating effect what you get work done what you loss h1 h4 COP h2 h1 24 24 Test Rig 25 25 Objectives Official Determine by quantitative measurement how well the mathematical models (theoretical equations) of the compressor, condenser, evaporator represent what actually happens. Draw the actual cycle on the P – h diagram. diagram Compute the coefficient of performance COP. Technical Report Evaluate the performances of the refrigeration cycle and components What is wanted from the report P – h diagram COP 26 26 405 AIR COMPRESSOR 2103393 ME Lab Non ME, Section 4 & 7 Second Semester, Academic Year 2553 Department of Mechanical Engineering Chulalongkorn University 27 Theory: Single Stroke Compressor http://www.tpub.com/content/doe/h1018v2/css/h1018 v2_85.htm 28 28 Theory: Indicator http://www.oldengine.org/members/diesel/Indicator1. htm 29 29 Theory: Indicator http://www.oldengine.org/members/diesel/Indicator1. htm 30 30 Theory: Polar Planimeter http://reckonsurveying.com/page8-10.html 31 31 Test Rig 32 32 Objectives Official To learn how to make measurements of indicated horsepower (Ihp) and brake horsepower (Bhp) To investigate the performance of a single stage, reciprocating air compressor under conditions of constant speed Technical Report Evaluate the performances of the air compressor What is wanted from the report Bhp & Ihp – pressure ratio at a constant speed Mechanical efficiency – pressure ratio at constant speed 33 33