Factors relating to the development of a pink

advertisement

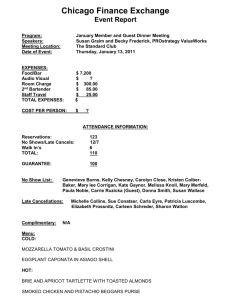

Factors relating to the development of a pink discolouration defect in commercial cheese – a review D.F.M. Daly l, 2, P.L.H. McSweeney2, J.J. Sheehanl lTeagasc Food Research Centre, Moorepark, Fermoy, Co. Cork, 2 School of Food and Nutritional Sciences, University College Cork Presentation Overview Manifestation of pink discolouration defect in cheese Review of theories and hypotheses from international research undertaken to date Research themes Different cheese-types +/- Annatto Conclusions Future research requirements Cheese Grading Appearance, texture and flavour Sporadic inconsistencies in cheese appearance may result in a downgrading of cheese Potential market loss Pink discolouration defect Problem across the globe Occurring in many different cheese-types Producers affected to varying degrees Occurrence within cheese Pink 10mm discolouration wide border Pink blotches within Discolouration first of noticeable running inside at surface cheese observed at ~block 1 month cheese andpost block block penetrating 15 mm from into manufacture discolouarion along external block ~ 20mm surface apparent curd junction Previous research Pink discolourations have been reported in a range of ripened cheese varieties Italian-types Swiss-types Cheddar-types Mould-ripened cheeses Producers have reported losses due to pink discolouration Extent of the problem hasn’t been quantified 2 to 5% of Cheddar and Colby in supermarkets in US (Dairy Field, 1999, Food Product Design 2000) Little consensus exists as to what exactly the pink discolouration is and what are its underlying causes Defect arises intermittently with use of same starter cultures for production. Why ? Cheese with/without colourants Cheeses such as Cheddar and other territorial-type cheeses often are coloured to give an orange to red colour Other cheeses do not have added colour Main colouring agent used in Annatto This review will consider separately development of a pinking defect in cheeses with With added annatto Without added annatto Cheddar type: with added annatto The principle pigment in annatto is cis- bixin, a carotenoid Also present, as minor constituents, are trans- bixin, cis-norbixin and trans-norbixin Annatto (in solution) can range from reddish/orange to yellow depending on the oxidation/reduction potential and pH (Barnicoat, 1937; Tharp and Young, 2003) Annatto, as a carotenoid, is sensitive to oxidation in foods (Smith et al., 2006) This oxidation is exacerbated by the presence of light and heat. Cheddar type: with added annatto Interaction between CO2 and high-intensity light leads to the oxidation of the bixin and a change in cheese colour (Colchin et al., 2001) Major factors that were associated with this discolouration were High intensity fluorescent lighting in display cases pH levels in cheese of 5.4 or more CO2 Oxidation the bixin Presence of oxygen in theof packaging Suggestion: producing Cheddar and Colby cheese within a pH range of 4.8-5.1 and use of packaging material such as foil laminate film to block light and oxygen (Food Product Design, 2000, Dairy Field, 1999). Cheddar type: with added annatto The effects of light type, temperature and pH were evaluated on stability of annatto colorants in cheese (Hong et al., 1995 a) Pink discolouration intensity is dependent on the ratio of red and yellow components remaining in the sample As cheese pH values reduced from 5.4 to 4.8: b* values (yellowness) were reduced at a faster rate compared to a* (redness) values resulting in an formation of a pink colour at the cheese surface Proper packaging films (Low oxygen transmission rate) are critical to reduce lipid oxidation and pink discoloration effectively in annatto coloured cheeses, aluminium foil laminate provided greatest stability for cheese colour. (Hong et al., 1995 b) O2 Other Factors with annatto ? Gouda (Discolouration at surface) Interactions between nitrates (added to prevent late blowing) and annatto in plastic surface coating Possibility Presence of bacteria with a high nitrate reducing capacity = higher nitrite in the rind Together with annatto and an increase in pH lead to pink discolouration (Pelaez & Northolt, 1988) Processed cheese Pink discolouration in processed cheese is associated with: Annatto containing high levels of norbixin High heat treatment during processing Use of aged cheese (proteolysis) Use of certain emulsifying salts (phosphates) Cheddar type: with added annatto Pink material from defective Cheddar cheese consisted of norbixin (pink coloured) associated with phospholipid (preventing resolubilisation of norbixin), β-casein and three unidentified peptide components (Govindarajan and Morris, 1973) Model studies indicated that localised decreased pH (due to hydrogen sulfide production) resulted in a microfine precipitation of norbixin No further research reported on this mechanism within cheese to date Cheese with added annatto: Summary of Factors Fluorescent lighting Interaction between CO2 and high intensity light Oxidation of bixin Temperature due to bright lights? Packaging Oxygen transmission rates Lipid oxidation Foil laminate pH: Conflicting reports: pH > 5.4, fluorescent lighting & presence of O2 in packaging Decreased pH: Microfine precipitation of norbixin: phospholipid preventing resolubilisation of norbixin As pH decreased from 5.4 to 4.8: Pinking Presence of O2 and redox potential Cheeses without annatto Have considered cheeses with annatto Factors associated with pinking in non anatto coloured cheeses Some factors may overlap with cheeses with added annatto However, as no annatto present- what leads to a colour change ? Previous research-Italian varieties (Romano and Mozzarella) Certain strains of lactobacilli associated with pink defect While other strains never associated with appearance of discolouration Cheese produced from cultures associated with the discoloration had a higher oxidation-reduction potential (Shannon and Olson, 1969 a) Development pink discolouration was enhanced by penetration of oxygen and increased curing temp (Shannon and Olson, 1969 a) Screening test developed to predict cultures tendency to produce pink discolouration (Shannon and Olson, 1969 b) Milk-calcium carbonate medium (incubation for 10 day at 37 °C) Cultures have tendency to produce pink discolouration Previous research-Italian varieties In Mozzarella cheese it was postulated that all rod cultures may have the means to impart the characteristic defect to some degree (MSc thesis: Betzold, 2004) That study used the screening method by Shannon and Olson to screen cultures for Mozzarella manufacture Low correlation between predictive assay and presence of absence of pinking in Mozzarella cheese Suggested : higher rod : coccus ratio may potentially result in a greater chance of the defect occurring? Italian and Swiss varieties Grana cheese (Bottazzi et al., 2000). A pink discolouration intense ring under the cheese rind Associated with the biochemical behaviour of a specific Lactobacillus helveticus used as starter culture Cheese produced from this strain (prone to pinking) higher levels of soluble nitrogen, increased free amino acid levels Correlation between proteolytic activity and pinking? Swiss-type varieties Suggestion (Eye formation- aside - Park et al., 1967) Possibility that propionic acid bacteria strain may be a factor in pinking: strain specific Cheddar-type: non-coloured Proposed that Maillard reactions may be involved in the formation of pinking Proposed: At least three factors are required for pinking to occur in Cheddar-type cheese (Martley and Michel, 2001) Galactose must be present during ripening Low molecular weight nitrogen compounds (proteolysis) Establishment of a required critical oxygen level within the cheese Pinkish zone surrounding plug hole cavity Cheddar-type: without annatto Proposed that Maillard reactions may be involved in the formation of pinking Generally Maillard reactions require higher temperatures than those encountered in cheese ripening Interesting conference poster: Paramita and Broome, 2008 Hypothesised: Pink discolouration could be due presence of intermediate compounds of maillard reaction such as α-dicarbonyl compounds (glyoxal, methylglyoxal and diacetyl) in low temperature browning Demonstrated formation of coloured compounds in UHT milk system at 25oC Questions still remain: Source and stability of sufficient quantities in cheese ? Unproven in cheese system Mould-ripened cheeses Enzymatic oxidation of tyrosine to melanins by tyrosinase (Review of phenolic compounds- O'Connell and Fox, 2001) Reaction dependant on: pH, moisture content, Oxygen Free fatty acid Free amino acid levels (tyrosine) Presence of tyrosinase in cheese may be due to Contaminating microbes such as Pseudomonads, primary starters (Lactobacillus delbrueckii subsp. bulgaricus and other Lb. delbrueckii subsp.) Pigment-producing yeasts and moulds associated with browning of camembert cheese. (Carreira et al., 1998; Carreira et al., 2002) Hypotheses proposed from previous research on pink discolourations in cheese Coloured Compound Future- Key areas for focus Very complex- more likely a set of conditions than 1 factor Key issues Oxygen content and redox potential Influence of microbial diversity Presence of other microflora (NSLAB) Altered growth profiles of starter bacteria Particularly rod:coccus ratio Differing metabolic activity Influence of altered microstructure Presence of coloured compounds e.g. Carotenoids, Tyrosinase products- identification Pinking defect Flow Cell Cytometry Control Defect Dot plots of fluorescence of cells harvested from cheese samples Difference in patterns of bacterial cell viability and metabolic state between Control and Defect cheese Thank You Acknowledgements Martin Wilkinson & Dara Hickey University of Limerick for flow cell cytometry analysis This project is joint funded through the Irish Co-operative Organization Society Ltd.