job order vs process costing

advertisement

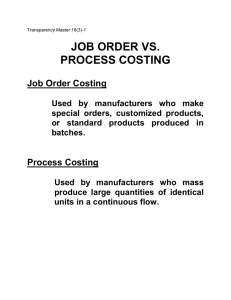

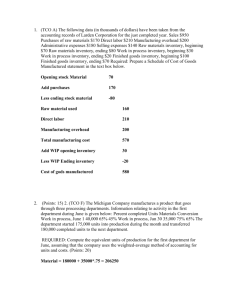

Transparency Master 2-1 JOB ORDER VS PROCESS COSTING Job Order Costing—used by manufacturers who make special orders, customized products, or standard products produced in batches. Process Costing—used by manufacturers who mass produce large quantities of identical units in a continuous flow. 44 Transparency Master 2-2 SIMILARITIES IN JOB ORDER AND PROCESS COSTING Both systems determine a product cost by measuring the amount of direct materials and direct labor used and allocating overhead costs. Both systems allocate overhead using a predetermined overhead rate(s). Both systems maintain perpetual inventory records with subsidiary ledgers for materials, work in process, and finished goods. 45 Transparency Master 2-3 DIFFERENCES IN JOB ORDER AND PROCESS COSTING Job Order: Costs are accumulated by job. Cost to Make One Unit = Cost of the Job No. of Units in the Job Process Costing: Costs are accumulated by department for a time period (for example, one month). Cost to Make One Unit in One Department = Department’s Cost for the Month No. of Units Produced during the Month To find the total unit cost, add the unit costs incurred in each department. 46 Transparency Master 2-4 FLOW OF COSTS IN A PROCESS COST SYSTEM Assume that Advanced Technologies, a computer manufacturer, makes its product in three departments: Assembly, Testing, and Packing. Materials and component parts are added in the Assembly Department. Packing materials are added in the Packing Department. Materials Cost of Materials materials used in purchased assembly Materials used in packing WIP—Assembly Materials Cost of units Direct Labor transferred Overhead to testing (applied) WIP—Testing Costs from Cost of units assembly transferred Direct Labor to packing Overhead (applied) WIP—Packing Costs from Cost of testing completed Materials units Direct Labor Overhead (applied) Finished Goods Cost of Cost of completed units sold units Cost of Goods Sold Cost of units sold Transparency Master 2-5 47 PROCESS COSTING DEMONSTRATION PROBLEM ADVANCED TECHNOLOGIES —ASSEMBLY DEPARTMENT Advanced Technologies produces notebook computers in three departments: Assembly, Testing, and Packing. Prior to the start of the production process, all the materials and component parts needed to assemble a computer are placed into a “kit.” Manufacturing begins when the Assembly Department receives a kit and begins putting the computer together. Therefore, all materials are added at the beginning of work in the Assembly Department. Conversion costs are added evenly throughout the assembly process. Assume that the Assembly Department of Advanced Technologies began April with 800 units in its work in process inventory. Assembly on these units was 3/4 complete at the beginning of the month. During the month, 3,000 units were started in the Assembly Department. At the end of the month, 300 of the units started were still in process; assembly on these units was 2/3 complete. The costs associated with production in assembly during April were as follows: Cost of units in beginning work in process inventory Cost of materials used in April Cost of direct labor and overhead for April 48 $228,000 630,000 527,000 Transparency Master 2-6 PROCESS COSTING PRACTICE PROBLEM ADVANCED TECHNOLOGIES —TESTING DEPARTMENT Advanced Technologies’ Testing Department receives completed computers from the Assembly Department. These computers are run through several diagnostic tests to ensure they work properly. The Testing Department began the month of April with 100 units in work in process. Testing on these units was 40% complete. During the month, 3,500 units were transferred in from assembly. There were 500 units in Testing’s ending work in process, which were 20% complete. The costs associated with production in the Testing Department during April were as follows: Cost of units in beginning work in process inventory Direct materials (transferred in from assembly) Cost of direct labor and overhead for April 49 $ 40,000 1,288,000 158,000 Transparency Master 2-7 PROCESS COSTING PRACTICE PROBLEM ADVANCED TECHNOLOGIES —TESTING DEPARTMENT Solution STEP 1: Determine the units to be assigned costs. Beginning Work in Process Inventory Units Started and Completed During the Month (3,500 – 500) Ending Work in Process Inventory Total 100 3,000 500 3,600 50 Transparency Master 2-8 PROCESS COSTING PRACTICE PROBLEM ADVANCED TECHNOLOGIES —TESTING DEPARTMENT Solution STEP 2: Calculate equivalent units of production. Materials equivalent units: Beginning WIP Inventory Units Started and Completed Ending WIP Inventory Whole Units 100 3,000 500 % Materials Added in April 0 100% 100% Equivalent Units 0 3,000 500 3,500 Whole Units 100 3,000 500 % Conversion Added in April 60% 100% 20% Equivalent Units 60 3,000 100 3,160 Conversion equivalent units: Beginning WIP Inventory Units Started and Completed Ending WIP Inventory 51 Transparency Master 2-9 PROCESS COSTING PRACTICE PROBLEM ADVANCED TECHNOLOGIES —TESTING DEPARTMENT Solution STEP 3: Determine the cost per equivalent unit. $1,288,000 Materials Cost/Equivalent Unit = = $368 = $ 50 3,500 equiv. units $158,000 Conversion Cost/Equivalent Unit = 3,160 equiv. units 52 Transparency Master 2-10 PROCESS COSTING PRACTICE PROBLEM ADVANCED TECHNOLOGIES —TESTING DEPARTMENT Solution STEP 4: Allocate costs to transferred and partially completed units. Cost assigned to the units in beginning work in process: Direct Materials Beginning WIP Balance Cost to Complete: Equivalent Units for April Cost per Equivalent Unit 0 $368 0 Total Cost Transferred to the Testing Department Conversion Cost 60 $50 $ 3,000 Total Cost $40,000 3,000 $43,000 (Continued) 53 Transparency Master 2-11 PROCESS COSTING PRACTICE PROBLEM ADVANCED TECHNOLOGIES —TESTING DEPARTMENT Solution (Concluded) Cost assigned to the units that were started and completed: Direct Materials Started and Completed: Equivalent Units Cost per Equivalent Unit Total Cost Transferred to the Testing Department 3,000 $368 $1,104,000 Conversion Cost Total Cost 3,000 $50 $150,000 $1,254,000 Cost assigned to units in ending work in process inventory: Direct Materials Ending WIP Inventory: Equivalent Units Cost per Equivalent Unit Total Cost of Ending WIP 500 $368 $184,000 54 Conversion Cost 100 $50 $5,000 Total Cost $189,000 Transparency Master 2-12 COST OF PRODUCTION REPORT Advanced Technologies Cost of Product Report—Assembly Department For the Month Ended April 30 UNITS WHOLE UNITS Units charged to production: Inventory in process, April 1 ...... 800 Received from materials storeroom................................. 3,000 Total units accounted for by Assembly............................. 3,800 Units to be assigned costs: Inventory in process, April 1 ...... 800 Started and completed in April .. 2,700 Transferred to Testing Department............................... 3,500 Inventory in process, April 30 .... 300 Total units to be assigned cost.. 3,800 EQUIVALENT UNITS Direct Materials Conversion 0 2,700 200 2,700 2,700 300 3,000 2,900 200 3,100 (Continued) 55 Transparency Master 2-13 COST OF PRODUCTION REPORT (Concluded) COSTS Direct Materials Units costs: Total costs for April in Assembly ........................ Total equivalent units ........................................... Cost per equivalent unit ....................................... Costs charged to production: Inventory in process, April 1 ................................ Costs incurred in April ......................................... Total costs accounted for in Assembly............... Costs allocated to completed and partially completed units: Inventory in process, April 1—balance ............... To complete inventory in process, April 1.......... Started and completed in April ............................ Transferred to Testing Dept. in April................... Inventory in process, April 30 .............................. Total costs assigned by Assembly...................... 56 COSTS Conversion $630,000$527,000 3,000 $210 Total Costs 3,100 $170 $ 228,000 1,157,000 $1,385,000 $ $ 0 567,000 $ 34,000 459,000 63,000 34,000 228,000 34,000 1,026,000 $1,288,000 97,000 $1,385,000 Transparency Master 2-14 Decision Making Using Process Cost Data Solution Materials Cost per Pound Shift 1 Shift 2 By Line Average Line 1 $6.00 $7.00 Line 2 $6.00 $7.00 Line 3 $6.50 $7.50 Line 4 $6.00 $7.00 By Shift Average $6.13 7.13 $6.52 $6.52 $7.02 $6.52 $6.65 It is clear from the table above that increasing the speed of the machines has a very negative impact on materials consumption. The materials cost per pound on Shift 2 averages a full $1.00 per pound greater than on Shift 1. What makes Shift 1 different from Shift 2? The speeds, the employees, the supervisors, and the time of day. Which of these is likely the cause of our problems? Line 3 gives us some additional clues. Line 3 has the highest average machine speed and the highest average materials cost per pound. Thus, the cost differences appear to be related to the machine speed issue. Apparently, headquarters management is expecting Bundy’s plant to perform up to the standard of some of the plants with newer equipment. Bundy’s plant appears to be unable to operate at the higher speeds without some major process engineering work. 57