Supply Chain Fundamentals: Matching Supply with Demand

advertisement

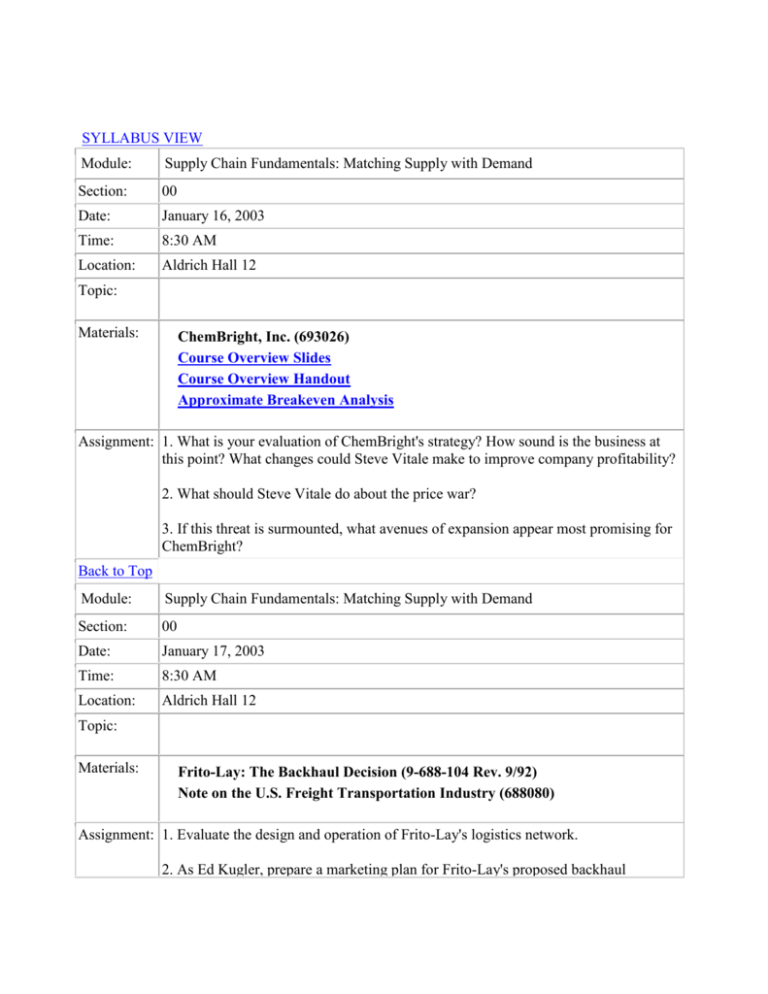

SYLLABUS VIEW Module: Supply Chain Fundamentals: Matching Supply with Demand Section: 00 Date: January 16, 2003 Time: 8:30 AM Location: Aldrich Hall 12 Topic: Materials: ChemBright, Inc. (693026) Course Overview Slides Course Overview Handout Approximate Breakeven Analysis Assignment: 1. What is your evaluation of ChemBright's strategy? How sound is the business at this point? What changes could Steve Vitale make to improve company profitability? 2. What should Steve Vitale do about the price war? 3. If this threat is surmounted, what avenues of expansion appear most promising for ChemBright? Back to Top Module: Supply Chain Fundamentals: Matching Supply with Demand Section: 00 Date: January 17, 2003 Time: 8:30 AM Location: Aldrich Hall 12 Topic: Materials: Frito-Lay: The Backhaul Decision (9-688-104 Rev. 9/92) Note on the U.S. Freight Transportation Industry (688080) Assignment: 1. Evaluate the design and operation of Frito-Lay's logistics network. 2. As Ed Kugler, prepare a marketing plan for Frito-Lay's proposed backhaul services. 3. Should senior management at Frito-Lay approve the backhaul proposal? If you believe they should, how should the backhaul program be implemented? If not, how should Frito-Lay address its rising distribution costs? Back to Top Module: Supply Chain Fundamentals: Matching Supply with Demand Section: 00 Date: January 23, 2003 Time: 8:30 AM Location: Aldrich Hall 12 Topic: Basic Inventory Management Materials: Excerpts from Chapters 4 and 5 from Production and Operations Analysis by Steven Nahmias. Inventory Slides Assignment: The reading for this class is fairly technical and not representative of the rest of the course. Do not worry if some portions are difficult to follow, especially the derivations for the formulas. However, an understanding of the economics of inventory is vital to be an effective supply chain manager. Click here for Assignment Back to Top Module: Supply Chain Fundamentals: Matching Supply with Demand Section: 00 Date: January 24, 2003 Time: 8:30 AM Location: Aldrich Hall 12 Topic: Materials: Hewlett-Packard: Deskjet Printer Supply Chain (A) - Stanford Case Table 1 from case Normal Distribution Slides HP Box/Distribution Handout Assignment: 1. What has caused the so-called inventory/service crisis? 2. What industry characteristics, product characteristics, and supply chain characteristics are particluarly important to Brent Cartier's problem? 3. List the important drivers of "safety stock". 4. How would you evaluate the various alternatives available to Brent Cartier to address the inventory and service problems? (If needed, use z = 2.05 to calculate a safety stock level for a 98% service level.) Please note the minor case typo: On page 1 of the case, there is a missing line in paragraph 3, line 6 that changes the meaning of the sentence. The sentence should read: "The distribution organization's pet peeve was forecast accuracy. It didn't feel that it should have to track and store warehouses of inventory just because the Vancouver Division couldn't build the right products in the right quantities." Back to Top Module: Supply Chain Fundamentals: Matching Supply with Demand Section: 00 Date: January 29, 2003 Time: 8:30 AM Location: Aldrich Hall 12 Topic: Materials: Tale of Two Electronic Components Distributors (697064) Guest: William Feth Assignment: 1. What is the value proposition offered by AESCO and ESCI? Identify the value added by each firm to the channel. Think about why OEMs might buy product from a distributor instead of buying directly from the manufacturer. 2. What do AESCO and ESCI have to do well to grow? What does the owner/president of each firm need to do well for his firm to be successful? 3. How might industry trends towards consolidation, globalization, and the Internet affect each of these distributors? Back to Top Module: Supply Chain Fundamentals: Matching Supply with Demand Section: 00 Date: January 30, 2003 Time: 8:30 AM Location: Aldrich Hall 12 Topic: Materials: Sport Obermeyer Ltd. (695022) Assignment: 1. What operational changes would you recommend to Wally to improve performance? 2. How should Obermeyer management think (both short-term and long-term) about sourcing in Hong Kong versus China? 3. Based on Exhibit 10 in the case, how should Wally plan production in November? Make sure to identify factors that would affect the timing and quantity of production decisions. Back to Top Module: Supply Chain Fundamentals: Matching Supply with Demand Section: 00 Date: February 6, 2003 Time: 8:30 AM Location: Aldrich Hall 12 Topic: Global Supply Chain Management Simulation Materials: "Making Supply Meet Demand in an Uncertain World" (HBR 94302) "Configuring a Supply Chain to Reduce the Cost of Demand Uncertainty". (Optional) GMSCS Record Sheet How the Board Casts its votes Assignment: The Global Supply Chain Management Simulation will allow you to manage the supply chain of a cell phone manufacturer. You will be put in charge of the introduction of two cell phone models, and will be required to design the product line, forecast demand, choose a set of suppliers with different cost and lead-time characteristics, and allocate production among your chosen suppliers. After completing the product and supply chain design phase, you will observe actual monthly demand, and will have opportunities to respond to unexpected events. The simulation is repeated over a four-year period, allowing you an opportunity to revisit your decision processes each year after learning from the feedback you receive about the previous year's results. At the end of each year, the company's virtual board of directors will evaluate your performance. In addition, profits for each year are computed. Team performance will be revealed in class on Thursday, February 6. Availability of Simulation The GSCM Simulation will be available for you to play any time between 11:30 am on January 30, 2003 and 8 pm on February 5, 2003. To run the simulation for class, you have been assigned to a two-person team, which we have found greatly facilitates learning. On Friday, January 24, you will receive an email from Maggie Davis that will specify your teammate, your team's log in ID, and your team's password. You and your teammate should find a time and location when you can take between 2 and 3 hours to run the simulation. You can run the simulation in the Shad R&T Lab, in Spangler, or from your home. Although the application works over a 56K modem, it is faster using a high-speed connection. It is also better to have the ability to listen to audio. Important: 1. Use Internet Explorer to run the simulations. 2. To log in to the simulation, go to www.enspire.com/apps/gscms. (Note: if your computer does not have Macromedia's Flash Player 5, the program will automatically link you to detailed instructions for downloading the player.) Enter your TEAM user name and password, and click Submit. When you click the SUBMIT button, a new screen will appear with the game buttons for each stage of the exercise. 3. When you and your teammate run the simulation, you must run through the entire 4-year period and submit those results without restarting the simulation. This set of team results will be tabulated and shown in class. You must complete all four years in order to have your data recorded. You are done with the simulation after you have answered all of the feedback questions at the end of year 4. 4. As you and your teammate run the simulation, please input the decisions you make and the rationale behind those decisions on the word document "GSCM Sim.Record Sheet," posted on the course platform. After completing the GSCMS record sheet, please save the record sheet as a Microsoft Word document with the name TeamXSim (using your unique team number in place of the letter X) and email to araman@hbs.edu and madavis@hbs.edu by 8 pm on February 5, 2003. Make sure to also bring a copy to the debrief session in class on Wednesday! 5. If you restart or refresh Internet Explorer you will lose your data from the current year. The simulation data is being recorded on the server at the end of each year, so if for some reason you do lose your internet connection or have to restart the simulation, you can quickly advance through the years you have completed until you reach the beginning of the year that you were last playing in. No data from completed years will be lost or overwritten. Once you get to the start of the year that you were last playing in when you lost the connection, all of your new data will be recorded again. You will know that your data have NOT been recorded if at the end of a year after visiting the board room you receive a "Server Timeout" error message. If the "Server Timeout" error message appears, click the "retry" button (do not click "continue" or your data for the year you just played will not be saved). If you get the error message again after clicking "retry", you should re-start Internet Explorer and re-run the most recent year. The complete server timeout error message reads: "Server Timeout: If you have disconnected from the Internet, please re-connect and click the retry button. If you cannot connect to the Internet, you may continue, but your data will NOT be saved. If you are connected to the Internet and still get this message, please contact support@enspire.com." 6. At any point in the simulation, you may use the game buttons to click back to previous decisions you have made in the same or previous years. 7. If you experience technical problems, please contact Enspire Learning at support@enspire.com. If you forget or lose your user ID or password, please contact Maggie Davis at madavis@hbs.edu. 8. You will also be provided an individual login ID and password. After you have submitted your team's results, you can log on as an individual player and run the simulation as many times as you wish prior to class, and anytime over the course of the next year. Back to Top Module: Supply Chain Fundamentals: Matching Supply with Demand Section: 00 Date: February 7, 2003 Time: 8:30 AM Location: Aldrich Hall 12 Topic: Review of Inventory Fundamentals Materials: Hamptonshire Express Problem #1 Fundamentals Review Slides Assignment: We will use this day to review multiple concepts relating to inventory models. 1. Examine the logic behind different components of inventory -- EOQ (or cycle stock), expected lead time demand, and safety stock. Why is each of them needed in a supply chain? Examine what would cause each of these components to be higher or lower. Examine problem # 1 below and determine Anna's optimal inventory level using the spreadsheet "Hamptonshire Express Proble #1." 2. Reflect on why "delayed differentiation" in the HP case reduced the need for safety stock in the European warehouse. How would the level of optimal safety stock change if the leadtime was 1.5 months instead of 1 month? What if the leadtime was variable too? 3. Look at Wally's production planning problem. Reflect QUALITATIVELY on how the problem can be solved -- do not seek to optimize the production quantities. Problem #1 Anna Sheen, upon graduating from a Boston-area university with a degree in journalism and operations research, returned to her home-town of Hamptonshire, Pennsylvania, to start a daily newspaper. The Hamptonshire Express emphasized local news which Sheen believed was not adequately covered by big-city newspapers such as the Philadelphia Inquirer, Pittsburgh Post-Gazette, and New York Times. Sheen daily wrote stories and articles around news and feature material that she gathered from around town, and type-set the newspaper using desktop software and a PC leased from a large Pittsburgh-area retailer. She estimated her lease cost at approximately $ 10 per day. The newspapers were printed overnight by a local printer at a marginal cost of $0.20 per copy (i.e., the printer charged 20 cents for each additional copy of a newspaper). Anna sold the copies the following morning from 6 a.m. to 10 a.m. from a newsstand at the intersection of Main Street and Center Street in the center of Hamptonshire. Newsstand rental was $30 per day. Express was sold to consumers for $1 per copy. Copies not sold by 10 a.m. were discarded. Demand for newspapers was unpredictable; Sheen estimated demand daily before delivering it to the printer. Based on data from similar entrepreneurial ventures and interviews with potential Hamptonshire customers, she estimated that daily demand for the Express was normally distributed with a mean of 500 and standard deviation of 100. a. How many newspapers should Sheen stock? Use the simulation in the spreadsheet “Hamptonshire Express: Problem #1” to identify the optimal stocking quantity. What is the profit at this stocking quantity? b. Verify that the value derived in part (a) is consistent with the optimal stocking quantity in the Newsvendor model. Back to Top Module: Incentive Alignment and Implementation Challenges Section: 00 Date: February 12, 2003 Time: 8:30 AM Location: Aldrich Hall 12 Topic: Materials: Barilla SpA (A) (694046) "The Bullwhip Effect in Supply Chains" by Hau Lee, V. Padmanabhan, and Seungjin Whang Assignment: 1. Diagnose the underlying causes of the difficulties that the JITD program was created to solve. It may be useful to reflect on your experiences with the Beer Game simulation you ran in first year TOM. 2. What are the benefits and drawbacks of the proposed JITD program? 3. What conflicts or barriers internal to Barilla does the JITD program create? What causes these conflicts? As Giorgio Maggiali, how would you deal with these? 4. As one of Barilla's customers, what would your response to JITD be? Why? 5. In the environment in which Barilla operated in 1990, do you believe JITD (or a similar kind of program) would be feasible? effective? If so, which customers would you target next? How would you convince them that the JITD program was worth trying? If not, what alternatives would you suggest to combat some of the difficulties that Barilla's operating system faces? Back to Top Module: Incentive Alignment and Implementation Challenges Section: 00 Date: February 13, 2003 Time: 8:30 AM Location: Aldrich Hall 12 Topic: Materials: Barilla SpA (B) (695064) Barilla SpA (C) (695065) Barilla (B) worksheets Assignment: Prepare: Barilla SpA (B) 1. What key learning should Barilla gain from the experience described in the (B) case? What are the main sources of the performance improvements the company has realized? 2. How shoud it use these results to convince distributors to use JITD? Prepare: Barilla SpA (C) 1. What are the greatest sources of the economic benefit that the JITD program is intended to provide? 2. Which ditributors should Barilla target for the JITD program? 3. What are the strengths and weaknesses of Barilla's approach to continuous replenishment? How could Barilla's JITD program be improved? Back to Top Module: Incentive Alignment and Implementation Challenges Section: 00 Date: February 20, 2003 Time: 8:30 AM Location: Aldrich Hall 12 Topic: Materials: Campbell Soup Company: A Leader in Continuous Replenishment Innovations (195124) The Costly Bargain of Trade Promotion, HBR Reprint 90201: to read postclass. (Optional) Assignment: 1. Evaluate Campbell's implementation of CPR. 2. How should Campbell structure prices for its CPR customers? What additional policies (if any) should it put into place for its CPR partnerships? 3. What changes should Campbell make to its internal processes? When should these changes be made? Back to Top Module: Incentive Alignment and Implementation Challenges Section: 00 Date: February 21, 2003 Time: 8:30 AM Location: Aldrich Hall 12 Topic: Materials: Hamptonshire Express (698053) Aligning Incentives for Supply Chain Efficiency (600110) Hamptonshire Problem #1 Hamptonshire Problem #2 Hamptonshire Problem #3a Hamptonshire Problem #3c Hamptonshire Problem #3d Hamptonshire Problem #4a Hamptonshire Problem #5a Hamptonshire Problem #5b Assignment: Read the Hamptonshire Express case. Download the 8 excel spreadsheets in the courseware area for today's class then answer the questions for each problem described in the case. Back to Top Module: Retail Operations Section: 00 Date: February 26, 2003 Time: 8:30 AM Location: Aldrich Hall 12 Topic: Materials: CompUSA The Computer Superstore (699026) Rocket Science Retailing is Almost Here: Are You Ready? Assignment: 1. Identify the opportunities and challenges facing CompUSA. 2. Why is a responsive supply chain important for CompUSA to be successful in its business? Identify the steps taken by CompUSA to improve its ability to respond to market signals. 3. How do CompUSA's corporate culture and HR policies affect its responsiveness? Back to Top Module: Retail Operations Section: 00 Date: February 27, 2003 Time: 8:30 AM Location: Aldrich Hall 12 Topic: Materials: Borders Group, Inc. (N9-601-037) Bob DiRomualdo Video Assignment: 1. How should Conacher deal with the technological changes impacting book retailing? Specially, how should he deal with the Internet retailing? You might want to compare the websites for Amazon.com and BarnesandNoble.com. 2. Can Borders integrate the capabilities of the Internet and the retail store? What is the role of phantom stockouts in achieving this integration? Back to Top Module: Retail Operations Section: 00 Date: February 28, 2003 Time: 8:30 AM Location: Aldrich Hall 12 Topic: Materials: "Execution: The Missing Link in Retail Operations" by Raman, DeHoratius, and Ton Assignment: 1. Identify examples of supply chain conformance problems that you have experienced either in your work or as a consumer. 2. How might these conformance problems affect supply chain performance? 3. How can companies improve conformance in their supply chains? Back to Top Module: Retail Operations Section: 00 Date: March 5, 2003 Time: 8:30 AM Location: Aldrich Hall 12 Topic: Materials: Supply Chain Management at World Co., Ltd. (N9-600-111) What is the Right Supply Chain for your Product? (HBR 97205) Assignment: 1. Examine the features of fashion apparel retailing in Japan. How can a company use its supply chain to compete in this environment? 2. World could replenish products in two weeks, and design and replenish new products in six weeks. Some retailers in the US have leadtimes of over six months to replenish similar products. Examine the supply chain at the World, and identify why the company is able to respond so effectively. 3. Can the World's supply chain processes be replicated at other apparel companies? What about non-apparel supply chains? Identify potential barriers. Back to Top Module: Coordinating Retail and Manufacturing Operations Section: 00 Date: March 6, 2003 Time: 8:30 AM Location: Aldrich Hall 12 Topic: Mass Customization in Upholstered Furniture: Marketing & Retailing Materials: Norwalk Furniture (A), 9-298-040 Assignment: Read the on-line case and view the video clips. The (B) Case, to be covered in class on March 12, looks at manufacturing and transportation issues for the same firm. 1. Evaluate Norwalk's business model. Examine the company's products, the location of its stores, and its use of various retail channels. 2. How should the company plan its future growth? Should the company partner with franchises, set up company owned stores, or sell through independent retailers? 3. Examine the economics of a franchised store. What can Norwalk Furniture do to make a franchise store more profitable? 4. Watch the related videos on the "store tour" and the "customer interaction process." How might the internet affect the future of Norwalk's marketing and retailing model? Back to Top Module: Coordinating Retail and Manufacturing Operations Section: 00 Date: March 12, 2003 Time: 8:30 AM Location: Aldrich Hall 12 Topic: Mass Customization in Upholstered Furniture: Manufacturing and Transportation Materials: Norwalk Furniture (B), 9-698-041 Paper version of case Assignment: Read the on-line case and view the video clips. 1. Identify the drivers of cost and leadtime in Norwalk's operations. How can the company reduce cost and leadtime? 2. Evaluate Francisco's proposal for cellular manufacturing. What operational challenges do you expect in implementing this proposal? 3. How would you expect Norwalk to perform in the future, given information in both Norwalk (A) and (B) cases? Back to Top Module: Coordinating Retail and Manufacturing Operations Section: 00 Date: March 13, 2003 Time: 8:30 AM Location: Aldrich Hall 12 Topic: Materials: Chapter 7: "Financial Strategy" from Retailing Management by Michael Levy and Barton A. Weitz (1-698-023) "Linking Finance and Operations in Retailing," by Fisher, Gaur and Raman (Posted below) Linking Finance and Operations Paper Finance and Ops Slide Set 1 Finance and Ops Slide Set 2 Research Paper relating to second slide set (quite technical!) Assignment: 1. Read the assigned chapter and examine the "Strategic Profit Model." Contrast the "profit path" and the "turnover path." The reading is fairly basic and all of you will follow the logic easily. (Note: There are typos at the top of page 217: The first ratio equals 1.15, not 2.5, and the second equals 1.83, not 4.) 2. Read the paper "Linking Finance and Operations" and reflect on the following questions: a. Why would you expect ROE and ROA to not differ among different segments of retailing? b. Would you expect inventory tuns and gross margins to differ among segments? c. Critique the methodology in the paper to relate long-term stock market value and various operational measures. 3. Think about the following questions before class: a. Why have retail inventory turns not improved in recent years, despite the considerable investment in IT? (Data show that average inventory turns across all retailers have stayed steady at about 6 turns per year over the15 year period from 1985-2000.) b. However, during the same period, we find considerable variation in inventory turns at the firm level. For example, between 1985 and 2000, the Gap’s inventory turns ranged from a low of 3.6 to a high of 6.3, Best Buy’s from 3.8 to 9.1, and Wal-Mart’s from 4.9 to 7.2. What might explain this firm-level variation? c. How much might we expect a firm’s inventory turns to increase with additional capital investment (e.g. in IT, warehousing, etc.)? d.How can we compare the inventory productivity of two retailers, such as Target and Wal-Mart, which have different gross margins? Back to Top Module: Factor Markets and the Role of Intermediaries Section: 00 Date: March 14, 2003 Time: 8:30 AM Location: Aldrich Hall 12 Topic: Materials: Massimo Menichetti (686135) Assignment: 1. Analyze the "Prato system." How does it work? What is the role of the impannatore and how will that role change with the new technology? 2. Analyze the "telematics" proposal. Taking the perspective of Menichetti, how would you try to influence the architecture of the proposed system? What will CAD technology do to the structure of the industry in Prato? Back to Top Module: Factor Markets and the Role of Intermediaries Section: 00 Date: March 27, 2003 Time: 8:30 AM Location: Aldrich Hall 12 Topic: Li and Fung Materials: HBR Article: An Interview with Victor Fung "Fast, Global and Entrepreneurial: Supply Chain Management, Hong Kong Style" 98507 Opening Slides Assignment: 1. Why does Li and Fung "break up the value chain and rationalize where they do things"? How does this add value to the supply chain? 2. How does Li and Fung make the supply chain more responsive (i.e. reduce response time)? 3. What is the role of the "little John Waynes"? 4. Identify salient features of a "global" supply chain and how an intermediary like Li and Fung can add value to such a chain. Back to Top Module: Analytical Techniques for Supply Chain Management (Optional) Section: 00 Date: March 28, 2003 Time: 8:30 AM Location: Aldrich Hall 12 Topic: Analytical Session 1: Forecasting Time Series Materials: Read Chapter 2 in Nahmias book. Forecasting Data Introduction to Forecasting Assignment: Read pages 55-87 in Chapter 2 from Production and Operations Analysis by Steven Nahmias. Focus on the following sections. (Note: A data file for the assigned problems is posted in the courseware section for today's class. 1. In section 2.6, examine the various measures that have been identified to evaluate forecasts. Read example 2.1 to understand the approaches. Solve problem # 13 on page 66 (Problems for Section 6.) 2. Section 2.7 identifies "Moving Averages" and "Exponential Smoothing" as two techniques for forecasting stationary series. Solve problem # 16 on page 69 (Problems on Moving Averages) and problem # 22 on page 75 (Problems for section 7.) 3. Section 2.8 describes how regression analysis could be used for forecasting when the underlying series has trend. Example 2.4 on page 78 provides an example of how regression analysis can be used. Try to solve problem 2.4 on your own using Excel for the regression analysis (To use Excel for regression, look under the "Tools" menu for "Data Analysis"--the rest of the steps will hopefully be obvious. If not, use the Help tool in Excel to learn about the "Regression analysis tool." Check your numbers with Nahmias'.) 4. In section 2.9, read example 2.6, example 2.7. Solve problem #33 on page 87 Back to Top Module: Analytical Techniques for Supply Chain Management (Optional) Section: 00 Date: April 2, 2003 Time: 8:30 AM Location: Aldrich Hall 12 Topic: Analytical Session 2: Inventory Models Materials: Chemplan Corp.: Paint-Rite Division (191090) Nopane Advertising Strategy (893005) Chemplan Data Nopane Data Nopane Regressions Assignment: Please plan to come prepared to discuss Dan Williams questions in the Chemplan case. Specifically: 1. Run the regression using Construction Index as an independent variable. What are the R-squared and standard error? Predict the paint sales for 1965 given that estimated Construction Index in 1965 is 50. 2. Run the regression using Loans and Construction Index as explanatory variables (Sales = a1 + b1* Loan + c1* Construction). What are the R-squared and standard error of the regression? Is this regression better than the regression in question 1? Predict the paint sales for 1965 based on the regression model. 3. What happens when we use all three independent variables in the regression (i.e., Sales = a2 + b2*Year + c2*Loan + d2*Construction)? For Nopane: Assume that you believe Silk’s hypothesis about competition, which is that "Nopane’s competitors will react to our national strategy the same way as they did in the test." Further assume that Silk decides to spend an advertising level of $8.00. 1. Which regression or regressions would you use to estimate the effect of emotional versus rational copy? 2. Using your selected regression or regressions, calculate the best estimate (point forecast) of the unit sales of Nopane in a Segment A sales territory if: (a) you use emotional copy for your advertising campaign, (b) you use rational copy for your advertising campaign. 3. Which type of copy, the emotional or rational approach, would you prefer? The Nopane data file and regressions are located in the courseware section for today's class. The Chemplan data file is located in the courseware section for today's class. Back to Top Module: Analytical Techniques for Supply Chain Management (Optional) Section: 00 Date: April 3, 2003 Time: 8:30 AM Location: Aldrich Hall 12 Topic: Analytical Session 3: Aggregate Production Planning Materials: Introduction to Aggregrate Planning:, Nahmias pp. 113-135 Aggregate Production Planning Slides Assignment: For Introduction to Aggregate Planning: Read pp. 113-135 in Nahmias. 1. Focus carefully on the linear program formulation described in Section 3.5. 2. Explain the 4 constraints and objective function described on pages 131-132. 3. In class, we will demonstrate how such linear programs can be solved using Microsoft Excel "Solver" and we will examine how the output from "Solver" can be interpreted. 4. Solve problems 14 and 15 from page 129. Back to Top Module: Analytical Techniques for Supply Chain Management (Optional) Section: 00 Date: April 9, 2003 Time: 8:30 AM Location: Aldrich Hall 12 Topic: Analytical Session 4: Linear Planning Materials: Nahmias, pp. 161-191 Linear Programming Case Study: Short-Run Manufacturing Problems at DEC, pp. 375-379 B&F. Rolltop Desk Example APP Problems 14 and 15 APP and LP Slides DEC Data Problem 3.34 DEC Datat for LP LP Slides Assignment: We will review concepts from Linear Programming and discuss the case "Short-Run Manufcaturing Problems at DEC." Please attampt to formulate the decision problem at DEC as a linear program. I recognize that some of you, because you are new to linear programs, might find this exercise challenging. Try to solve the problem using Excel solver. Back to Top Module: Analytical Techniques for Supply Chain Management (Optional) Section: 00 Date: April 10, 2003 Time: 8:30 AM Location: Aldrich Hall 12 Topic: Analytical Session 5: Inventory Models Materials: Revenue Management at Atlantic Air Yield Management at American Airlines (2-698-034) Airatl Atlantic Air Solutions Assignment: Read "Yield Management at American Airlines" for an overview of the use of quantitative tools applied to yield management in the airline industry. Read the case "Revenue Management at Atlantic Air" and analyze the two scenarios described on page 9, using the spreadsheet model for the case that is posted on the course platform Back to Top Module: Analytical Techniques for Supply Chain Management (Optional) Section: 00 Date: April 16, 2003 Time: 8:30 AM Location: Aldrich Hall 12 Topic: Analytical Session 6 Materials: Guest: Tim Murnin from Manugistics Ch. 11 - Designing and Managing Supply Chains Today's Agenda Software Selection Process Assignment: Back to Top Module: Analytical Techniques for Supply Chain Management (Optional) Section: 00 Date: April 17, 2003 Time: 8:30 AM Location: Aldrich Hall 12 Topic: Ananlytical Session 7 Materials: Arrow Guest: Steve Kaufman Operational Execution at Arrow Electronics Assignment: Back to Top Module: Analytical Techniques for Supply Chain Management (Optional) Section: 00 Date: April 24, 2003 Time: 8:30 AM Location: Aldrich Hall 12 Topic: Ananlytical Session 8 Materials: i2 Technologies, Inc. (699042) Guest: Sanjiv Sidhu, Founder, Chairman, CEO will attend via videoconference. Class will meet in Aldrich 112 this day. Assignment: 1. Identify the factors behind i2's success. Why is the company's stock valued so highly by investors? Examine the company's products, its sales and implementation process, its SOA process, etc. 2. Hasso Plattner, co-CEO of SAP was quoted saying, "We're SAP. We dominate the most important category of enterprise software. We intend to control all the enterprise software our customers use. If our partners cross us, we will crush them into dust". Given SAP's ambitions, comment on i2's future in the Enterprise Application Market. (“The E-Ware War: Competition Comes to Enterprise Software,” David KirkPatrick, Fortune, December 7, 1998) 3. Comment on i2's plans to become an e-BPO company. Back to Top Module: Analytical Techniques for Supply Chain Management (Optional) Section: 00 Date: April 25, 2003 Time: 8:30 AM Location: Aldrich Hall 12 Topic: Course Wrap Up Materials: PLEASE NOTE; THIS CLASS IS REQUIRED FOR ALL CMSC STUDENTS, NOT JUST THOSE TAKING THE ANALYTICAL TRACK. Sample Student Paper 1 Sample Student Paper 2 Last Day Slides Assignment: Class discussion will focus on the articulation of course learning. Students should come to class prepared to share their key learnings from the course. In addition to providing a forum for discussing learnings from the course in general, this final class will allow an opportunity for those who took different "tracks" to share their learning from those different experiences with each other. Those who wrote papers should be prepared to share with others in the class their key learnings from their research; those who took the analytics track should be prepared to share their key learnings from the analytics sessions with those who wrote papers. Back to Top Module: Analytical Techniques for Supply Chain Management (Optional) Section: 00 Date: May 1, 2003 Time: 8:30 AM Location: Aldrich Hall 12 Topic: Materials: Assignment: Back to Top Final Guidelines