ME100 Lecture Notes – Introduction to Heat Transfer

advertisement

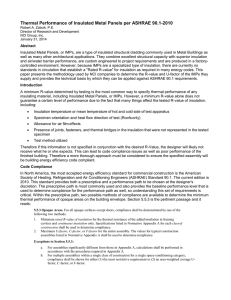

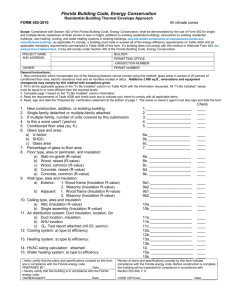

ME100 Lecture Notes – Introduction to Heat Transfer S. Lambert, Fall 2005 Objective: We need to calculate the heat loss for a house, Figure 1. Q, heat loss Tin Tout Figure 1: Schematic of heat loss model from a house. Background: In general, there are several types of heat transfer, including conduction, convection, and radiation. Conduction is the process we will focus on. It is the transfer of heat energy through a material, driven by a temperature gradient. Convection involves the transfer of energy by movement of a fluid, such as air. Radiation involves the transfer of heat energy through disorganized electromagnetic propagation. All forms are relevant to our application. However, we can make a very reasonable approximation by considering conduction and convection only, and by treating both using the same form of equation. Conduction: Empirical evidence (testing) suggests that heat transferred by conduction depends on the temperature difference, material properties, and geometry. The equation we will use is: k Q A T x where Q is the rate of heat transfer through the material, A is the area through which the heat is flowing, k is the thermal conductivity of the material, x is the distance through which the heat must travel, and T is the temperature difference across the material. This situation is illustrated in Figure 2. A = hl h Q Q Tout Tin x l Figure 2: Heat flow through a wall. The old-fashioned units for energy are British Thermal Units, or Btu, so that energy flow rate, Q, can be expressed as Btu/hr. The corresponding unit for temperature difference is Fo, distance is ft, area is ft2, and thermal conductivity is Btu/(Fohrft). It is common to combine the thermal conductivity and the thickness of the insulating material as a thermal conductivity or resistance – thermal resistance is the inverse of thermal conductivity. In imperial units, the thermal resistance, R-value, is the thickness in ft divided by the thermal conductivity: x R k o 2 The units of R are F ft hr/Btu. The heat transfer equation can then be expressed as: A Q T R The resistance values are often tabulated per inch of thickness – simply multiply this value by the thickness to get the total R-value. Table 1 provides the R-value per inch for some common insulating materials. These have been taken from Appendix B of “Modern Hydronic Heating for residential and light commercial buildings”, by John Siegenthaler, Delmar Publishers, 1995. Material Fiberglass insulation Blown cellulose fibre insulation Foam in place urethane insulation Extruded ploystyrene panel insulation Concrete Brick Softwood Plywood Drywall Vinyl siding R-value Foft2hr/Btu per inch 3.17 – 3.5 3.1 – 3.7 5.6 – 6.3 5.4 0.10 0.2 – 0.4 0.9 – 1.1 1.24 0.9 0.61 (for all thicknesses) Table 1: Insulating values (R-value) for common materials (ref: Siegenthaler, 1995). The total resistance value for a composite structure such as a wall is obtained by adding the resistance contributions from each layer. The resistances are combined in series since the heat flow, Q, is the same through each section of the wall. For example, for a typical wall consisting of 0.5” drywall, 3.5” fiberglass insulation, 0.5” plywood sheathing, and vinyl siding, the total R-value based on average values would be: 3.17 3.5 R 0.5(0.9) 3.5 0.5(1.24) 0.61 13.35 2 Note that the wall will contain other important elements such as an air infiltration barrier (towards the outside of the house) and a vapour barrier (towards the inside – warm side), but these do not contribute significantly to the insulating value. Missing from this estimate is any consideration of the resistance to heat transfer due to the air film next to interior of exterior surfaces. They can be approximated using recommended R-values as given in Table 2, also from Siegenthaler, 1995. Film Description Inside Air Films: Horizontal surfaces with upward heat flow (ceiling) Horizontal surfaces with downward heat flow (floor) Vertical surfaces with horizontal heat flow (wall) 45-degree sloped surfaces with upward heat flow Outside Air Films: 7.5 mph wind on any surface (summer conditions) 15 mph wind on any surface (winter conditions) R-Value o Fft2hr/Btu 0.61 0.92 0.68 0.62 0.25 0.17 Table 2: Equivalent thermal resistance of air films (ref: Siegenthaler, 1995). For our example, we would add 0.68 for the interior wall and 0.17 for the outside wall (winter), for a total R-value of 14.20. In our house model, we need to evaluate the total heat loss from all surfaces. These surfaces (walls, ceilings, windows, doors) are acting in parallel, so we can determine the heat loss through each surface and add these values to get the total. Heat Loss through Walls: The original walls consist of approximately 20” of stone/concrete on the outside, a 1.5” air gap, 3/8” of wood lath and 1/2” of plaster. The R-value can thus be approximated as: Material Outside Air Film Stone/Concrete Air Gap Wood Lath Plaster Inside Air Film Total Thickness R/in R n/a 0.17 0.17 20 0.1 2.00 n/a 0.68 1.36 0.375 1 0.38 0.5 0.9 0.45 n/a 0.68 0.68 5.04 Heat Loss through Ceiling: Similarly, the R-value for the ceilings can be approximated as: Material Thickness Outside Air Film n/a Roof Sheathing 1 Cellulose Insulation 4 Wood Lath 0.375 Plaster 0.5 Inside Air Film n/a Total R/in R 0.17 1 3.4 1 0.9 0.62 0.17 1.00 13.60 0.38 0.45 0.62 16.22 Heat Loss Through Windows: The house has single pane windows with a separate storm window, for a total of two panes. The glass itself provides little insulation value, so the effective R-value for each window can be approximated as four air films in series, one on the outside and three interior, for a total R-value of 0.17 + 3(0.68) = 2.21. Heat Loss Through Doors: The original doors were solid wood, approximately 1.5” thick, so the effective R-value can be approximated as 1.5(1.0) = 1.5. Heat Loss Through Basement: In addition to any insulation on the basement walls, the ground surrounding the basement will provide some insulation value, which will vary with the depth. Siegenthaler (1995) suggests the following formulae to estimate the R-value of a basement wall. For the first 2’ below grade: R = Rfoundation wall + Radded That is, the first 2’ of wall below grade should not take advantage of the insulating effect of the ground. For my house, there is no added insulation, so the effective R-value can be estimated from the resistance due to 20” of concrete foundation (R = 2) and one interior air film for a total R-value of 2.68. Note also that I estimate that the foundation wall extends approximately 1’ above ground level; this is reflected in the dimensions provided in the spreadsheet. For the next 5’ below grade: R = 8 + 1.126Radded Here, no advantage is taken of the foundation wall, although we could perhaps add the effect of the interior air film. For our case, there is no added insulation, so the effective Rvalue of the wall from 2’ to 7’ below grade is 8.68. Air Infiltration: Heat can also be carried out by air moving through the building envelope. The amount of heat loss will depend on the quantity of air leakage, which is dependent on the quality of sealing and the size of the house. Siegenthaler (1995) recommends the following values for the number of air exchanges per hour: Floor area (ft2): “Best” Quality “Average” Quality “Poor” Quality 900 or less 0.4 1.2 2.2 900 – 1500 0.4 1.0 1.6 1500 – 2100 0.3 0.8 1.2 over 2100 0.3 0.7 1.0 Table 3: Air change rates, N, in exchanges per hour (ref: Siegenthaler, 1995). In addition to the above factors, add 0.1, 0.2, or 0.6 for each fireplace of best, average, or poor quality, respectively. The heat loss due to air infiltration, Qi, can then be estimated using the following equation: Qi = 0.018NVT where 0.018 represents the heat capacity of air in Btu/ft3/Fo, N is the number of air changes per hour, V is the interior volume of the heated space in ft3, and T is the temperature difference in Fo, i.e., the inside temperature minus the outside temperature.