Hydro solution a key component for smelter modernization in BC

Hydro solution a key component for smelter modernization in BC

One of two penstock connection tunnels.

A privately owned hydro station with a maximum capacity of approximately 900 MW has been producing electricity since the 1950s and is now being upgraded to ensure reliability for the next

60 years.

The upgrade project, located south of Kitimat, British Columbia, Canada, is being implemented in two phases. Phase 1 covered interconnections between the new tunnel (T2) and the existing tunnel (T1) penstocks, including isolation valves, piping and access tunnels. In Phase 2, T2’s remaining 7.6 km will be bored through rock running parallel to T1, and a new intake structure including gates and trashracks will also be completed.

Hatch has been involved with the project since the early tunnel assessments and risk studies in

2007, then progressed through prefeasibility and feasibility studies, and onto final design of the tie-in works. We also provided construction support during Phase 1, working alongside the owner’s construction manager.

Our final design for Phase 1 included six 3.3 m diameter butterfly valves and associated hydraulic power units, an emergency backup diesel generator and permanent power system, and 200 m of 3.3 m diameter penstock installed in 4.2 m high tunnels. We provided all detailed construction drawings and specifications for the underground/geological, general civil/structural, electrical, and mechanical works.

Throughout the project, our team worked closely with the client’s management team to deliver a cost-effective solution in a short construction and shutdown window, while maintaining the high project quality targets.

Major components:

Underground works including caverns, penstock connection tunnels, surge shaft, one permanent access adit and two construction adits

New penstocks (involving transitional diameters and structural joints/supports), one large guard valve chamber, and biplane butterfly valves (D=3.3 m) in series

Power upgrades including new transformer, switch gear and backup generator

Key achievements:

Optimum layout and dimensions for the interconnection works aimed at minimum energy loss and construction costs

Underground excavation as close as 3 m to live penstocks while the power station was operating

A tight construction schedule was maintained despite major constraints: o Continual release of environmental flow for the downstream river o Natural weather and water flow constraints o Completion of the final tie-in works within an allowed power disruption of only nine weeks coinciding with the low-generation season

Design development of new bi-plane butterfly valves in series and in close proximity, while avoiding adverse cavitation and oscillation impacts

Efficient use of enhanced computational methods for structural (FEM) and flow (CFD) analyses for various parts of the interconnection structures and flows

Phase 1 was successfully completed in late 2013, and design studies for Phase 2 will begin soon.

When complete, the upgrade is expected to take the 60-year-old generating station well beyond 100 years.

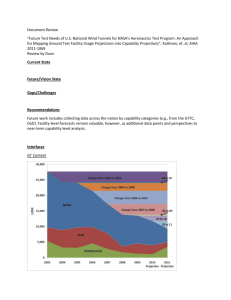

3D view of penstock tie-in between two tunnels involving bend, contraction, and support plates.

New guard valves inside newly excavated chamber.

For more information, please contact:

David J. Daw, MESc, PEng

BC Regional Manager, Waterpower Vancouver, British Columbia, Canada

+1 604 630 7333

DDaw@hatch.ca