इंटरनेट

मानक

Disclosure to Promote the Right To Information

Whereas the Parliament of India has set out to provide a practical regime of right to

information for citizens to secure access to information under the control of public authorities,

in order to promote transparency and accountability in the working of every public authority,

and whereas the attached publication of the Bureau of Indian Standards is of particular interest

to the public, particularly disadvantaged communities and those engaged in the pursuit of

education and knowledge, the attached public safety standard is made available to promote the

timely dissemination of this information in an accurate manner to the public.

“जान1 का अ+धकार, जी1 का अ+धकार”

“प0रा1 को छोड न' 5 तरफ”

“The Right to Information, The Right to Live”

“Step Out From the Old to the New”

Mazdoor Kisan Shakti Sangathan

Jawaharlal Nehru

IS 11639-1 (1986): Criteria for structural design of

penstocks, Part 1: Surface penstocks [WRD 14: Water

Conductor Systems]

“!ान $ एक न' भारत का +नम-ण”

Satyanarayan Gangaram Pitroda

“Invent a New India Using Knowledge”

“!ान एक ऐसा खजाना > जो कभी च0राया नहB जा सकता ह”

है”

ह

Bhartṛhari—Nītiśatakam

“Knowledge is such a treasure which cannot be stolen”

18: 11639 ( Part 1 ) .. 1986

(Reaffirmed 2001 )

flu/ian Standard

CRITERIA FOR

STRUcrURt\L DESIGN OF PENSTOCKS

PART 1 SURFACE PENSTOCKS

INDIAN STANDARDS INSTITUTION

M,~~.t\K

£JIJ\V ~".

9

1l,r\lI~\l)CK

NF.'V

Gr4

nm.m

SJ1,\11

1100(;2

4.*\f.\R

1\L\1tO

AMENDMENT NO. 1 DECEMBER 2008

TO

IS 11639 (PART 1) : 1986 CRITERIA FOR

STRUCTURAL DESIGN OF PENSTOCKS

[Page 9, clause 6.1.5.1(b)] ― Substitute ‘ f 3 =

µ1 PAc

A

’ for ‘ f 3 = µ1 PAc ’.

2

(Page 11, clause 7.1) ― Substitute ‘ Sx, Sy =

fx + fy

fx − fy

±

+ q2

2

2

’ for ‘ Sx, Sy =

fx + fy

±

2

( fx − fy ) 2 + q 2 ’.

2

(WRD 14)

Reprography Unit, BIS, New Delhi, India

IS I 11639( Part 1) • 1916

Indian Standard

CRITERIA FOR

STRUCTURAL DESIGN OF PENSTOCKS

PART 1 SURFACE PENSTOCKS

Water Conductor Systems Sectional Committee, BDC 58

Chairrrwl .

SlIal P. M. MAN.

39 Sbivaji Co-operative Housing Society

Pune

M""b",

R,prI"rding

08181' ENODf&JIlR

Bhakra Beal Management Board, Chandigarb

SKl\I SUDIlR8BAN KUMAR (AICIl'll4l, )

C:smr ENOnnDn

Mukerian Hydel Project Design, Chandigarh

DIBBCTOR (Alt"nal.)

C B I 11., ENG I N 11 11 B (CIVIL Karnataka Power Corporation Limited, Bangalore

DJDSIGNS)

SURI P. R. MALLmABJU:NA (Altlt1UJl,)

CalEr ENGINB.a ( GB1UmA.L )

Public Works Department, Madras

CRlllr EXGm_ ( IRRIGATION) ( .Alt"n." )

CHIB" ENGm.a (HP)

Tamil Nadu Electricity Board, Coimbatore

SUPJIlRIN'1'1INDDfG ElfonfJum ( AIUr".t, )

CBIBI' ENGINBBB (IRBIOATIOK Public Works and Electricity Department, Mysore

SOUTH)

SUPBRllftElmJXO EMGJ1C'DB. ( Alt",.at, )

SIIBI C. ETTY DA.BWIN

In personal capacity (Dunery Mutlada P.O.,

TrivtJntlrum)

Central Soils aDd Materials Research Station, New

Delhi

DIREOTOR

D..UTY DIRIICTOB (

DIRZCTOR (HeD-I)

DEPUTY DIRECTOB (

DB A. K. DUBS

AlllrfUll, )

Central Water Commission, New Delhi

HCD-I ) (Alt"".")

Central Minin, Research Station Unit, Roorkee

D1\ J. L. jmTHwA (AlI",",t,)

Smu j. P. GUPTA

Power House DesigDl, Irrigation Department,

Roorkee

SR.l A. P. GtrPT A ( Alumau )

SKBJ M. V. S. IYENOAR

Hinduatan Construction Co Ltd, New Delhi

SHRI M. G. KHAN (AlterM")

( C",,';nUld 011/Jag' 2 )

I

C>C~"'1986

INDIAN STANDARDS INSTITt1rION

This publication is protected under tIM lrulia CoJ!1rilAt Ad (XIV of 1957) aDd

reprodue:tloo la whol. or In part by aDy meaDi except with written penniulon or the

pub"• • IhaII be deemed to be aD IDlrlapm_t of copyright under the laid Act.

II • 11631 ( .... t 1 ) .. 1. .

( Con'inuld .from /HII' 1 )

R''''''IfI'in,

Mmajn.l

JOJN'1'

D'.BlIlOTOB,

RUB"RCU

(GE·I1 )

SURt

P. N. KIIAB

SHRt

A. K.

M:&STA

SUI S. C.

BALI (

MBKBER ( CIVIL)

DR B. PAn

Reaearch Desi._ and Standard. OrranizatioD,

Lucknow

National Hydroelectric Power Corporation Ltd,

New Delhi

Nadonal Projects Construction Corporation Limited,

New Delbi

AI,,,,",,,)

Kerala State Electricity Board, Trivaadrum

Water Resources Development Trainiq Centre,

Roork..

SIlBI G. P AKT

Geololical Survey of Iadia, New D.lhi

SHRI N. K. MANDWAL ( AllmuJl,)

SHIU A. R. RAIOHU.

In personal capacity ( 147, Gartd;',..,ar, BomN.1 )

SUllI Y. RAilA KRISHNA RAO

Andbra Pradesh State Electricity Board, Hyd4Prabad

S'O!'llBl1ftmfDINO EIfGDfJDlt

( DUIOK AND PLAN1(ING ) ( Altma4U)

REFR.SUTATIVJD

..

Central Water and Power Research Station,

SHBI A. V. GOPALAJcBJ8BNA (AII6f'1UJu)

SURI G. V. SATHAY1II

General De.ilftS Or,uization, N..ik

88RI S. C. SilK

Allam State Electricity Board, Guwahati

SBBIN.K.DA8(~hnuu)

Central Electricity Authority, New Delhi

DB H. R. SUARMA

Himachal Prad.b State

Electricity

SSRI A. K. SaIXANTIAB

*

SHaI RutJODH SINGH

SURI G. RAMAN,

Pune

Board,

Sundemapr

(AlI"na")

Director General, lSI (&-of/ido Mllllh,,)

Director ( Civ En" )

S",,'ary

SHar HBKANT KtrKAR

Deputy Director ( Civ Enn ). lSI

Panel for Penstocks and Anchor Blocks, BDC 58: P6

C"IIHn',.

KUKAJU E. D1VATIA

National Hydroelectric Power CorporatioD Limited,

New Delhi

Mnnhn,

SURI M. L. AQ()A aw AL

Bhakra Deal MaD.gement Board. Chandigarb

SSKI Y. P. NAYAR (All,mat,)

DIRECTOR (T & P)

Irrisation Work&, GovemmeDt of PuDjab. Chandigarh

SmnoR Da10N EWOINlIlER ( Altmlat. )

DtRlIlCTOB (HOD·} )

Central Water Commission, New Delhi

DEPUTY DIRECTOR ( HOn.! ) ( AltmalJ")

SJl1\l N. C. J,UN

Irrigation Department, Government of Uttar Pradesh

Lucknow

DR ZAWAR MaBDI

Bharat Heavy Electric." Ltd, Bhopal

SSRI j. L. KBoal: ( Altmaat, )

( CMlillIIId", /141' IS)

.Chairman for the meetins.

2

II, 11631 ( ••"t 1 ) • 1986

Indian Standard

CRITERIA FOR

STRUCTURAL DESIGN OF PENSTOCKS

PART 1 SURFACE PENSTOCKS

o.

FOR EWOR D

0.1 This Indian Standard (Part 1) was adopted by the Indian

Standards Institution on 31 January 1986, after the draft finalized by

the Water Conductor Systems Sectional Committee had been approved

by the Civil Engineering Division Council.

0.2 Conduits carrying water from surge tanks or directly from a

reservoir, fore bay , to the power house are known as penstocks. Penstocks

are generally of concrete or steel or a combination of both. The pressure varies from minimum at the upstream end to the maximum at the

junction with the scroll case.

1. SCOPE

1.1 This standard ( Part 1 ) lays down the various forces acting on surface

penstocks and structural design of penstocks conveying water under

pressure flow cpnditions. However, this does not cover specials of pen..

stocks like penstock supports, manifolds, bends, expansion joints,

manholes, branch outlets, etc.

2. NOTATIONS

2.1 For the purpose of this standard, the following notations shall have

the meaning indicated against each:

A = cross-sectional area of pipe shell material, mm!

Ar = cross sectional area of stiffener ring, mm s

b =- width of ring girder or stiffener ring, mm

C == moment coefficient

E - modulus of elasticity

fl, fl, fa == longitudinal strelsel, N/mml

If, = secondary bending Itress, N/mm l

IS I 11&31 ( Part 1 ) • 19.

fa -

total circumferential Itres., N/mml

f, - total longitudinal stresl, N/mml

I

L

M, Ml

= height of .tilFener ring or riDg girder, mm

= span length of pipe, mm

=

moments

P - internal pressure including water hammer, N/mml

PI = total reaction at support, N

=- shear stress, N/mm2

, == radius of pipe shell, mm

'1 - mean radius of shell, mm

S =a hoop stress in pipe, N/mml

S, .. equivalent stres., N/mml

S., S. = principal stresses, N/mml

T = temperature rise or drop, 00

I = thickness of pipe shell, mm

'1 == thickness of stiffener ring or ring girder, rom

W =- total distributed weight, that i., lelr-weight of shell

weight of water, N/rn l

.

WI = total weight, that is, weight of shell

weight of water,

N

Z os section modulus of pipe shell, rna

~ =s coefficient of linear expansion or contraction of pipe shell

material, per 00

.",. =a coefficient of friction.

ql

+

+

3. DATA REQ,VIRED

3.1 The following data is required

penstocks:

for the structural design of

a) General drawing of installation;

b) Complete longitudinal profile;

c) Type of penstock;

i) Free penstock pipe laid in a tunnel, and

ii) Steel lined pressure shaft.

d) Geological data;

i) Geology of area.

ii) Type of ground/rock,

iii) Bearing capacity of ground,

4

• a 11&39 ( Part I ) • 19.

iv) Shear properties of soil,

v) Modulul of deformation, and

vi) Seismic coefficient.

e) Climatic conditions;

i) Temperature ( maximum, mean, minimum, by day and

night and in summer and winter ),

ii) Wind conditions ( direction and maximum speed ), and

iii) Snow conditions ( period and average depth of snow).

f ) Hydraulic data;

i) Diameter of penstock, and

ii) Discharge through penstock.

4. LOADS ON PBNSTOCK

4.1 The following are the main loads considered for the design of

penstocks:

a) Internal water pressure,

b) Weight of penstock and water, and

c) Temperature.

In addition, the other loads considered depend ing on location

are:

a) wind load,

b) snow load, and

c) seismic forces.

4.2 The loads given in 4.1 are of the following nature:

a) Permanent loads,

b) Intermittent loads, and

c) Exceptional load •.

f.2.1 The loads of permanent nature are the forces which act upon

the penstock in normal operation. They correspond to:

a) The maximum operating pressure which is the sum of maximum

Itatic pressure and over pressure due to water hammer under

normal operating conditions, taking into account the oscillations

in surge tank;

b) The weight of penstock and water between the supports;

c) Spacing and type of supports;

5

IS a 11639 ( ....t 1 ) • 1911

d) The difference between the temperature which may exist in the

penstock in normal operation and the temperature exi.ting when

coupling up the sections during erection;

e) Friction at suppon,; and

f) Temperature variation.

4.2.2 The loads of intermittent nature are the forces which though not

excep tional, do not arise often.

The two main cases are:

a) Penstock during filling, and

b) Empty penstock under partial vacuum.

The forces to be taken into account in each case correspond to:

a) The weight of penstock and water between the supports,

b) The type and spacing between supports,

c) The temperature effect, and

d) Friction at supports.

In addition to the forces enumerated in <a> to (d), intermittent loads

may also occur due to wind or snow load and earthquakes.

4.2.3

are:

a)

b)

c)

The loads of exceptional nature that may act upon the penstocks

Shop or site test;

Erection stresset;

Bad operation of safety devices during filling such al non-operation of air valves which would create vacuum inside during

empting operation of penstocks;

d) Pressure rise caused due to unforeseen operation of regulating

equipment of turbine/pump distribution:

i) In case of impulse turbine. pressure rise due to needle slam

on JOSI of oil pressure or mechanical failure; and

ii) In case of reaction turbine, turbine gates may be closed

instantaneously at any time by action of governor manual

control of main relay valve or by the emergency solenoid

device.

e) Stresses developed due to resonance in penstock (A. rar as

possible, the frequency of penstock pipe in any reach shall not

match with the frequency of machine, frequency of vortex shedding in the draft tube, frequency of the system, etc, and resonance

shall be avoided )j and

f) Seismic forces.

6

IS I 1163. ( Part I ) • 1• •

5. STRESSES IN PENSTOCK SHELL

5.1 The streases in the penstock shell of surface penstocks are subjected to

circumferential and longitudinal Itrelsel. The Itreuel in pipe at the

mid-span and at the lupports are as below:

a) AI mid-J/Jdn:

i) Hoop strelses developed due to internal pressure equal to

sum of static pressure due to maximum water level in reservoir or surge tank plus the dynamic pressure due to water

hammer al calculated for operating conditions,

ii) Longitudinal stressel developed due to its own weight aDd

weight of water by beam action,

iii) Longitudinal streue. developed due to sliding friction over

the supports, and

iv) Longitudinal stresses developed due to expanaion or contraction of penltock shell due to variation of temperature.

b) AI supports:

i) Circumferential Itresses developed at the supports due to

bending caused by internal pressure,

ii) Longitudinal Itresses due to secondary bending moments

caused by the restraintl imposed by ring girder or stiffener

rings,

iii) Longitudinal stresses developed at the supports due to beam

action, and

iv) Longitudinal stresses developed by forces enumerated in 4.1.

5.2 The stresses in penstock shell shall also be checked to withstand the

stresses developed due to intermittent and exceptional loading and for

the following forces:

a) Longitudinal stresses developed due to earthquake and wind,

b) Circumferential stresses developed due to pressure rise called by

non-operation a8 specified in 4.2.3 (d),

c) Longitudinal stresses developed due to wind, and

d) Stressel developed due to filling and draining of penstocks.

6. METHOD 01' CALCULA.TlON

or STRESSES IN PIPE SHELL

6.1 The streues for different force. shall be calculated .. given in 6.1.1

to 6.1.7.

7

.. r

11639 ( Part 1 ) .1986

6.1.1 Hoop Stress Du« to Int"."al p"uu"

'.1.1.1 The hoop stress developed due to internal pressure i. given

by:

S =- .!!-

t

NOTB - The internal pressure P is due to stacic head

+ dynamic head.

1.1.2 Longiludinal Joint Effiei,,,e} ( , )

6.1.2.1 It Shall be taken as 1-0 for fully radiographed joint.

6.1.3 LOfI,;tudinal StrtSJtJ DUI to B,arn Action

6.1.3.1 The stress developed due to self-weight and weight of water

pipe Ipanning over supports due to beam action .hall be calculated by

the following formula:

M

f - T N /m l

where

AI - bending moment caused due to self-weight and weight

of water.

NO'1'JI - BeDdiq moment, M. at mid-span and at support shall be calculated for

each ca.. eoDiideriDi the pipe a. a beam Ipaoninl continuoUily over intermediate

supporta

6.1.3.2 The longitudinal stre,sea developed due to radial strain

eaused by internal pressure may be taken equal to 0'303 times the hoop

ten'ion.

1.1.3.1 The longitudinal atressel developed due to seismic forces in

the pipe spanning over the support due to beam action is equivalent to

seismic coefficient times stresses calculated in 6.1.3.1. These stresses

should be added to stresses calculated in 6.1.3.1.

6.1.3.4 The longitudinal stresses developed due to wind or snow

load acting on the pipe spanning over the support are calculated as given

in 6.1.3.1, where bending moment, M, is caused due to wind load or snow

load.

6.1.t Longi'~tlinal S"'SJ DIAl to Sliding Fritl;t)n

6.1.t.l The maximum longitudinal stress developing over all

supports within a section between an expansion joint and the subsequent

support .haJl be calculated by the formula:

I'.

IPf + aEP/

J2 = -Awhere

Pf =- total sliding friction in section between an expansion

joint and subsequent support = ,..W, Cos ~,

---r-'

8

IS I 11639 ( Part 1 ) • III'

a

= eccentricity of frictional force relative to centre line of

Z

= section modulus of pipe shen, and

penstock,

~ =

angle of section under consideration with the horizontal.

The coefficient of friction, "" between shell and support shaU be

taken from Table 1.

TABS 1 DICTION COEFFICIENTS FOR DIPnRENT MATERIALS

( Claus, 6.1.4.1 )

SL

No.

TVI'E OJ' SOI'I'ORT

i) Steel OD concrete

ii) Steel on concrete with asphalt rootiDI paper in

hetwe~n

iii) Steel on steel ( rusty )

iv) Steel OD ItMI ( Irea~ed )

v) Steel on steel with two layers of

service .heets in between

vi) Rocker support

vii) Roller support

Yiii) Concrete on concrete

0"60

0'50

graphite

0'15

0'10

0'75

6.1.5 T emplraturl StrlSS

6.1.5.1 Longitudinal stresses caused due to expansion or contraction

of pipe shell shall be calculated by the following formulae:

a) Pipe shell without expansion joint

fa = EccT

b) Pipe shell with expansion joint

fa = 1-'1, PAc,

where

1-'1 = coefficient of friction between packing material and pipe

shell. and

Ac -=- contact area between penstock shell and packing material

in rnrn'[,

6.1.6 Circumfirent;al Bending Stress,s at SupjJorts

6.1.6.1 Circumferential stresses at supports due to bending caused

by internal pressure shall be calculated by the following formula:

M - C PI r

9

II • 1113. (Part 1 ) • 1986

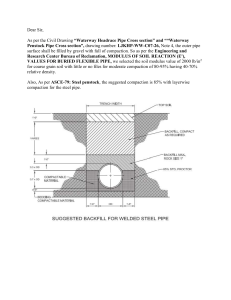

The value of C for different angles of support is given in Fig. 1. The

effective length or shell resisting the bending moment is equal to 4 times

the radiu. of the shell.

0·10

I I I I

I

I

I I I I "

, I '"

0-08

,~,

.' .

0-08

I

~I

'.

j

,

u

.....

~ 0-0'

u

\:

I

Pw.~~Tt~o=fACT~N

J

I

'I

OF

,. RADIUS OF SHELL

-1"'l'iI~

\£.

~

0·02

u

MOMENT

""'lli

,.. ...

r-_ ......

---

"'"

"......

..... ~~ "-

- "" ....

~

~

~

......

40

60

~AlU£S

'I

J

I

IJ

'~~:'V

~

~,....~~

~

J

J

J

I

j

,~,_,: If

~"'" --.... ~

0'02

20

J

• ~~j

~:,,- v

~~ ~""""

Fro. 1

I

I I I I

IV

~

J

j

M.CX~'

1

~

- .....

80

~~J

,f/

l/

V

100

120

Of 8 IN OEGRE ES

VARIATION OP CIRCUMPBRBNTlAL MOMENT AROUND

SHELL RBSTINO ON SADDLB SUPPORT

6.1.7 Longiludin41 B",ding StrlSI DUI to &sl,a;,. by Rin, Girders or Sti/fi"".

Rill,s (JI IhI Supports

6.1.7.1 The secondary bending strea due to restrain shall be

calculated by the formula:

It ==

1°82 ( A' -~

+ 1-561 ttl "

A,

x.!!t

NOTa - Thil stre.. is local and tbe efFect shall b. talkeD for a distance of Slf where

f - 1°285 on either side of tb. supportiq riaa and pipe thickness shall be increased.

tIrt

if required, in this zoneo

10

IS I 11639 ( Part 1 ) • 1118

7. EQ,UIV ALENT STRESSES

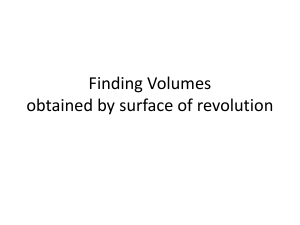

7.1 The circumferential and longitudinal stresses obtained as lpecified in

6.1.1 to 6.1.7, shall be combined to obtain equivalent strellel in accordance with Hencky Mises Theory, given by the formula:

s, = ttl Szl + 811 ±

5 , S.,

z

= fz ;

SX S"

f., :l: 4~(~/s~--2-Ji~.,~)ir--+-r

where

Iz - longitudinal stress,

!., hoop stress, and

q = shear strel.

c=

The equivalent stresses may be readily obtained from Fig. 2.

8. LINER THICKNESS

8.1 The liner thickness of an exposed penstock shall withstand the

equivalent stress as specified in 7_

8.2 Notwithstanding the thickness obtained as specified in 8.1 and

regardless of pressure, a minimum thickness of liner shan be provided to

resist the distortjon during fabrication and erection. A minimum thickness of D

~o50

em is recommended where D i. the diameter of shell

in em.

8.3 No corrosion allowance i. recommended. Instead, it is suggested to

paint the inside and the outside surface of pipe with a paint conforming

to the relevant Indian Standard.

9. WORKING STRESSES AND FA.CTOR OF SAPETY

9.1 Normal Operatbal CODdidoa

9.1.1 It is recommended that under normal operating condition AI

specified in 4.2.1, the working stresses with a factor of safety of 3 based

on the minimum ultimate tensile strength shall be adopted for design

but in no case the maximum stress.s obtained in 7.1 shall exceed 0'5

times the specified minimum yield strength of material.

9.2 latermltteat LoacU•• CODdltlo.

9.2.1 I t is recommended that under intermittent loading condition as

specified in 4.2.2, the working stre••es with a factor of safety of 2-5 based

on minimum ultimate tensile strength shall be adopted for designs but in

no case the maximum lueues obtained in 7.1 shan exceed 2/3 the

specified minimum yield strength of material.

11

18 • 11639 ( Part 1 ) • 1986

,"""

~ ~~

"""

,L

l/

2 ..........

~

O~

~

8~

~

6~

~

4./

.J!I'"

2~

~

~

~

~

~

~

~

I.-"'""'

~

~

~

~I"""'"

.....

,

-.. "' "- -, 1/ V I' \

r--- -, "- r'\ /'

r'\ ~ \

r"""-~

~ ~~ """"'"

~

, V'\ '\ \ ,

- ---- - V""'- ''\"" r\ \ \ I' ,

- -_ - "-V V" " \ , ,

'V '\ " ,

' ,

, I

----

~~

~

r-,

.....~ ~

r""'~

~

~

.....

"""'" ~

"-

~

~/

\

<, /

/ l\

\

,.....V \/, \1 \J

~

- /' ~

,

~

\

\

,

l

~

"..

:J

.l

J

J I I J J J J

J J J 1/ I l I I I I

r

if

1/

II I I{ II If

'

~

I J J J J

I I I

J

J

I I I JI I

I

If If f

v

,

I

rJj

V I I I v if I

~

/

l/ ~

/ If V V !/ / / 1/ / / / / / /

,V ~V ~ V / V 1/ J I ~ :,J ) J j I j J

V

:/ ~ ) ~~ lf~ J ~~ v / /

i> ~v /

v / V V V / V / 1/ /

6[/ ~V / [/ I)(

~/

~V / / / / / / ) )

./

V /~ ~ P' / / / / ~

8/

l/ ~';'~V V )< / ~ ,.~ v V /

1/

1/ ~ l / ./'" v: l/ /'). V V V

,/V

~ l/ ~' r\ V /

/

,/' l/ ~'"

V / ~ V V ~

1/

V 1/ / " V V

~

l/ .,..

"""'" ~ ./

I' V

..1../ ~ /" V V

if""'"

L/ ,.,.. ,;' ~" V .-/" V

V ~V Y ~~

6/

~

V .,V t>

l/

/ (

f

~

~

~

~

~

,,

l

J

l I I

/ 1/ 1/ 1/ II II 1/ V 1/ II.

oV ~ ~ if I 1/ 1/ 1/ a,

l>< ) 2/ J rt.j J ltij I j to) / ~21 J tV / ~/ /

2[/ ~

~

'--

,-..

~~~

~

./

/ '\

"-

I

J 20

,

x

,

"

~

ill"""

ill"""

~

TENSION. THOUSANDS

2 EQ.UIV ALENT STRESS DIAGRAM

9.3 Exceptio. COllciltloD

9.3.1 Under exceptional loading condition as specified in 4.2.3, it is

recommended that the working stresses with a factor of safety 2'0 based

on minimum ultimate strength shall be adopted for design but in no

case the maximum stresses obtained in 7.1 shan exceed 0'8 times the

specified minimum yield strength of material.

Flo.

12

IS a 1163' ( Part I ) · 1986

( Conl;nu,dfrom pag. 2 )

Mmabers

R,prls,nt;",

Kerala State Electricity Board, Trivandrum

A. R. RAGHAVAN

Tamil Nadu Electricity Board, Madras

Snn r T. RAMASWAMY

Indian Hume Pipe Co Ltd, Bombay

81)1\1 B. RAMA8WAMY (AII,rnat,)

DR H. R. SUAHMA

Central Electricity Authority, New Delhi

SlUU B. TnoMA8

Central Water & Power Research Station, Pune

SHRI R. VIJAYAN'

In personal capacity ( ECONS-Engi",,,s & Corantltllllts,

35/136 KamalhHath LAn" eIKh", )

SURl N. G. KURUP ( Altlf"a/, )

SlUU

SHRI

c. GENlt8A PILLAl

13

INTERNATIONAL SYSTEM 0. UNITS ( 81 UNITS)

•••• VDlt.

SYIIBOL

Q;UAlftl'l'Y

UNIT

LenKth

Mau

Time

Electric current

Thermodynamic

temperature

LuminoUi intenalty

Amount of substance

metre

kllopam

second

ampere

llelvin

K

candela

mole

cd

mol

m

kl

A

...........tarJ Valt.

Q.uAlCTnr

Plane augle

Solid IUIIle

Ul'II'r

radiaD

Iteradian

SYMBOL

rad

It

Derlyed Ualta

Q,U.&.NTITY

UlfIT

8'1'1180£

Porce

EnefIY

Power

Flus

Flus deDiity

Prequency

Electric conductance

Electromotive forc.

newton

joule

N

Pr-.ur., Itrea

watt

weber

t.labuts

,iemea

volt

palCal

J

W

Wb

T

H.

S

V

P.

n.rmJTIOK

N =- 1 kl.m/sl

J-1N.m

I w- t J/s

1 Wb - 1 v.,

1 T .. 1 Wb/ml

I Hz - I cIs (a-I)

I S-IA/V

I V-IW/A

I P. - I N/m l