HESpec - Department of Defence

advertisement

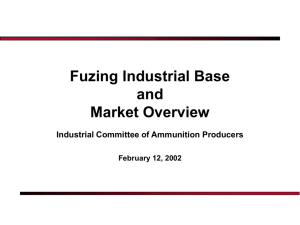

MORTAR SPECIFICATION Bomb Mortar 81 mm HE 1. GENERAL PURPOSE AND SCOPE This specification must establish the performance, manufacture, test and acceptance requirements for Bombs Mortar 81 mm HE with point detonating / Super quick / delay fuze or equivalent hereafter known as mortar bomb 2. PRINCIPLE DOCUMENTATION a. Military Specifications All applicable military specification to be listed here b. Military standards All applicable military standards to be listed here. Military Standard documents to be supplied. For example: Mil – Std – 105 E Sampling procedures and tables for inspection by attributes Mil – Std – 331 Fuze and Fuze Components, Environmental and Performance Tests for Fuze Design Safety Hazard Assessment –STANAG 4187 /MIL-STD-1316 c. Military documents To be specified here d. Other standards and specifications To be specified here e. Applicable documents Reference Numbers for drawings to be listed here and attached as Annexes f. Drawings Reference Numbers for drawings as listed above to be attached as Annexes g. Technical Product specification A complete Technical product specification is required in English to include i. Detailed specification for each component ii. All relevant quality documents 1 ANNEX A iii. A complete list of all components and materials out sourced including names and country of origin of the outsourced components / materials. h. Environmental All items relating to ammunition & packaging must conform to best International practise w.r.t to environmental safety and recycling. Compliance with all Environmental standards to be listed here. e.g. ISO 14001 3. REQUIREMENTS a. Item definition – Function ,use and deployment i. Bombs Mortar 81 mm HE with point detonating / Super quick / delay fuze or equivalent The Bomb Mortar 81 mm HE with point detonating / Super quick / delay fuze or equivalent is to be an explosive projectile shot at high angles of flight. The primary application of the mortar bomb is to be anti personnel and must be capable of being effectively used against soft skinned vehicles. The fuze must have a delay option which can be externally set, which allows penetration of heavily wooded areas and soft roofs of buildings, when necessary. On firing of the bomb the fuze must arm on set back and remain safe in front of the muzzle before being fully armed. The distance in front of the muzzle that the bomb remains safe must be provided. On impacting the target area the bomb must detonate instantaneously. If the delay option is selected the time for detonation to be supplied here. Fuzes containing a pyrotechnic train (with the exception of the delay composition) in the detonation sequence shall NOT be accepted. b. Item diagrams Cross sectional detailed drawings of mortar bomb and its packaging to be included here. c. Interface definitions Mortar Weapon. The current 81 mm Long barrel mortar in service with the Defence Forces of Ireland is the Hotchkiss Brandt 81 mm Long Barrel 81 –MO-61-L (Smooth bore). It has the following properties - inside diameter 81m Length 1450 mm Max barrel pressure 800 bar 2 ANNEX A Range tables for all charges must be supplied for this barrel d. Major components i. Point detonating / Super quick / delay fuze or equivalent The Point detonating / Super quick / delay fuze or equivalent must be double load safe. The fuze must NOT be susceptible to copper azide corrosion. The successful company must agree to the conducting of a double Load test of the fuze during quality audit / acceptance testing. The construction of the fuze must fulfil all the requirements of the norm MIL – STD – 1316 Fuze design, Safety criteria for STANAG 3525 Design Safety Principles for fuzing systems The external measurements must fulfil the requirements figure of the NATO norm. STANAG 2916 Nose Fuze Contours and matching projectile The following information is required of the fuze: 1. A complete description of the fuze 2. A complete description of all modes of operation e.g. mechanism, arming etc 3. All safeties incorporated in the fuze 4. The compositions (incl weights) of all explosive components contained in the fuze 5. Diagrams / schematics and all its modes of operation of the fuze. 6. The sealant used between fuze and bomb body. 7. Quality documents for all components and components/ materials outsourced must be supplied. 8. Name of the Manufacturer of the fuze and its identification designation. ii. Bomb Projectile Body with Explosive filling The hollow bomb projectile body must be manufactured to accommodate the tail fin assembly and fuze ( in conformance with NATO norm STANAG 2916) . The bomb projectile body is to be of a spindle shape design. 3 ANNEX A The bomb projectile body must be filled with a High Explosive filling and painted and marked in accordance with standard NATO markings. An X-Ray examination of the Bomb Body and HE filling will be conducted on a representative sample of the ammunition Lot during acceptance testing to ensure that the HE filling has been filled correctly and is NOT filled with voids or piping problems. All quality documents of components must be supplied in English. All documents relating to the out sourcing of materials for components must be supplied in English The following information is required of the HE filling 1. 2. 3. 4. Chemical compositions (incl weights) The method of filling in the bomb body The internal body lacquer between HE filling and bomb body Quality documents for all components and components outsourced must be supplied. 5. Name of the Manufacturer of the HE Filling and its identification designation. iii. Tail Fin Assembly The tail fin assembly must provide flight stability to the bomb and carry the propulsion unit of the bomb. The tailfin must be designed to accept augmenting charges. The tailfin must be either 1. Manufactured from an extruded aluminium bar as a one-piece unit. It must be glued and screwed onto the bomb body unit and torqued to ensure a locked joint or 2. An integral part of the bomb body. All quality documents of components must be supplied in English. All documents relating to the outsourcing of materials for components must be supplied in English. iv. Primary cartridge A complete description is required of the 1. Chemical compositions (incl weights) of each energetic component 2. Diagrams/schematics of Primary cartridge. 3. Details on sealant used between primary cartridge and tail fin assembly. 4. Detail on material and sealants used on primary cartridge. 4 ANNEX A 5. The maximum and minimum pressures produced following initiation 6. The history of stability tests conducted 7. Name of the propellant manufacturer and its identification designation. 8. Quality documents for all components and components outsourced. All quality documents of components must be supplied in English. All documents relating to the outsourcing of materials for components must be supplied in English v. Augmenting (Increment ) charges The augmenting charges must be identically shaped additional charges capable of being fitted securely on to the tailfin of the bomb body. The augmenting charges must consist of a celluloid moulded container (or similar manufacture) filled with ballistite or similar type propellant. The augmenting charges must be colour coded for easy identification. The augmenting charges must be capable of being fitted around the tailfin shaft next to the fin section. The augmenting charges are to be ignited by the primary cartridge. A complete description of 1. Chemical compositions (incl weights) of each energetic component 2. Diagrams/schematics of Primary cartridge 3. The maximum and minimum pressures produced following initiation 4. The history of stability tests conducted 5. Name of the propellant manufacturer and its identification designation. Swabbing Out After firing 20 rounds at charge 2/3 there should not be sufficient residue remaining in the bore to cause a misfire. A misfire caused by debris should be considered a Major DEFECT. Test firing for residue will occur during quality audit / acceptance testing. All quality documents of components must be supplied in English. All documents relating to the outsourcing of materials for components must be supplied in English vi. Detonics All detonics of the bomb must be contained in the fuze. A detailed list 5 ANNEX A of all energetic components to be supplied complete with name of manufacturer and its identification designation. vii. Obturator Ring On firing the ring must expand under pressure to provide a tight seal between the bomb and barrel. This seal must provide a consistent pressure and resultant muzzle velocity. This obturator is normally a polycarbonate split ring on spindle bomb bodies. viii. Packaging The packaging must consist of inner and outer containers manufactured from recyclable material that conforms to all environmental standards for the storage of ammunition. Inner packaging to be quiver type container capable of storing two / three bombs. Outer container to be capable of storing inner quiver containers to a maximum of six bombs. Ammunition packaging must be kept to a minimum. The packed containers must be designed for stacking on top of one another and then palletised on a wooden UN pallet (or Euro pallet). Packed containers on pallets must be capable of being stacked on top of each other to a height of three (3) meters. All chemical protection for packaging used to be listed here. e. Characteristics i. Performance characteristics 1. Launching Velocity Information to be supplied as per table below. External Ballistic Performance Charge Velocity No. (m/s) Range (m) Accuracy Longitudal (m) Lateral (m) All propellant after ignition must be completely consumed and any resulting contamination and barrel burn out must be so small that they do not result in any malfunction of the weapon system. 2. External Ballistic performance The bomb when fired from the Brandt 81 mm LBM must land at a distance between 100 m and 5000 m from the firing point. (This is dependant on the augmenting charge used, the barrel elevation and the altitude of the firing point above sea level). 6 ANNEX A Typical values must be supplied in tabular form. 3. Terminal ballistic performance The bomb must detonate on impact either instantaneously or after a delay time of + 0.05 secs depending on the setting of the fuze. Details of lethal radius, number of fragments generated and kinetic energy of fragments on detonation at a distance of 10 m from the point of detonation to be supplied. 4. Dispersion What is the maximum dispersion in dimensions X (m) and Y(m) of 10 Bombs mortar at maximum charge under normal firing conditions using our specified mortar or an alternative mortar? This will be required to be verified during quality audit / acceptance tests. 5. Technical Data The following technical data must be supplied in this format: Technical data Functional temperature range -Storage -Function Weight (Flight weight) Min Max Functional elevation range Propellant gas pressure Launch acceleration Average muzzle velocity (V) Mechanical pre-tube safety time Mechanical arming time Flight time Range Average dispersion - Length - Width Reaction time - Instant function - Delayed function 7 ANNEX A ii. Physical characteristics All information in relation to weights, dimensions and arming times of the bomb mortar to be supplied here iii. Reliability The mortar bomb must have an operational reliability level of 95%. What is the % occurrence of a functional or physical failure of a mortar bomb or an element thereof which may lead to an uncontrolled explosion and / unsafe functioning? A statement defining reliability according to the manufacturer to be supplied here. iv. Range Tables All technical information must be supplied for the programming of Hand Held Mortar Fire control systems MORFIRE during quality audit / acceptance testing. A copy of the Range Tables in English to be supplied within each box of ammunition. v. Range vs. Height A chart illustrating trajectories of the mortar bomb when fired at an elevation of 45 degrees in a 81 mm Mortar barrel ( length 1450 mm) at the different charges. The following information to supplied at different charges Charges Velocities (m/s) Pressures (Kg/cm2) vi. Maintainability The ammunition must be maintenance free for a minimum of 10 years while contained in the specifically designed packaging and stored in temperature conditions ranging between – 10 degrees C and 50 degrees C. The shelf life of each component to be listed. The shelf life of the Bombs mortar to be stated. vii. Environmental conditions The 81 mm HE Mortar bomb must be resistant, safe and functional under all environmental conditions in accordance with MIL-STD-331. These tests to include 1. Transport Vibration. The bombs must be capable of withstanding a transport vibration test 2. Temperature extremes The bombs must be capable of being stored and fired in 8 ANNEX A temperature extremes between –20 degrees C and + 60 degrees C without deleterious effect. 3. Salt Spray The bombs must be capable of withstanding the salt spray test 4. Water tightness test. The bombs must be capable of withstanding the water tightness test before lot acceptance test viii. Transportability When the ammunition is packed and palletised, it must be capable of being stored, transported by road, rail, ship or aircraft without any detrimental effect to its functional and safety characteristics. Any ammunition packed in containers must be secured and shored to prevent accidental spillage. f. Design and construction i. Materials, processes and parts 1. Materials All materials used must comply to the specifications agreed and approved upon and shall be accepted and tested according to these specifications. All documents relating to the out sourcing of materials for components must be supplied in English 2. Manufacturing Processes All manufacturing processes must be such that a Lot or Batch of ammunition can be assembled and its components manufactured in one continuous and unchanged process. The process must be capable of manufacture within the dimensional and attributed requirements for characteristics that influence safety, form, fit and function parameters of the ammunition and include control measurements which are capable of identifying any changes in the process from its inherent capabilities. 3. Parts and Assemblies. All parts and assemblies are to be in conformance with the conditions and qualities as specified on the applicable drawings and specifications. ii. Electromagnetic compatibility The mortar bomb must not be influenced by electromagnetic fields generated in its immediate environment. iii. Identification and marking. The mortar bomb is to be painted and marked in accordance with approved marking drawings, NATO standard markings and to client specification. 9 ANNEX A iv. Workmanship. The workmanship and finish is to be of an acceptable quality and in conformance with standards used and expected in manufacturing military ammunition in accordance with International Best Practise. v. Interchangeability All components must be interchangeable for assembly purposes. vi. Safety 1. Muzzle safety. The fuze must not arm up to a minimum distance ( to be specified here) from the muzzle of the mortar barrel when fired at charge 0. This test is to be conducted during fuze Lot acceptance. Military Standard test reference to be listed and submitted. 2. Body safety. Empty bomb bodies are to be subjected to an internal pressure test during the manufacture process. Certification of test results conducted to be supplied. Military Standard test reference to be listed and submitted. 3. Double Load The fuze must have a double load safety feature, which will prevent detonation in the case of accidental double loading of mortar bombs in the barrel. Double Load test to be conducted during quality audit / ammunition acceptance tests. Military Standard test reference to be listed and submitted. 4. Drop Safety The ammunition must safely withstand a drop from 1.5 m both in its inner packing and without its inner packing. Military Standard test reference to be listed and submitted. vii. Engineering Design The design and construction of the ammunition must be such that there are no additional precautions to be employed by the user other than standard Ammunition and Explosive Regulations. g. TECHNICAL AND TRAINING MATERIALS i. Technical, Training and Instruction Materials (in English) must be made available as part of the contract. Specification, layout, electronic software (CDs, Charts, Software Programs etc.) and quantities to be agreed with customer prior to the awarding of contract ii. There is a requirement for the following to be supplied as part of the contract 10 ANNEX A 1. 2. 3. 4. 10 x Inert rounds c / w drawings 10 x Sectioned rounds c / w drawings 4 x sectioned Fuzes c / w drawings Operation and Function sequences of bomb and fuze on CD. h. QUALITY ASSURANCE PROVISIONS i. General 1. Responsibility for tests The manufacturer shall be responsible for the provision to an acceptance authority all gauges and target facilities necessary for the performance of the acceptance inspection of the complete mortar bomb. The acceptance authority reserves the right of inspection of Laboratory analysis certificates as well as production quality control certificates of raw materials and components used during the manufacturing of the applicable lot of ammunition The manufacturer shall use their own facilities or any commercial laboratory. The manufacturer shall be responsible for advising the client of the date, time and location of the required inspections and it is the client’s responsibility to ensure attendance of this representative, if required, at his own cost. The Director of Ordnance reserves the right to conduct a Quality Assurance Audit prior to the awarding of any contract. A test firing of ammunition may occur during this audit at the manufacturers location. The Department reserves the right to procure 100 Bombs Mortar for the Director of Ordnance for evaluation in Ireland as part of the tender evaluation The successful manufacturer must be capable of conducting firing tests on a Hotchkiss Brandt 81 mm Long Barrel 81 –MO61-L (Smooth bore) during acceptance tests. A Hotchkiss Brandt 81 mm Long Barrel 81 –MO-61-L (Smooth bore) will be supplied if necessary. The Country of the manufacturer / location of the acceptance tests must be capable of importing a Hotchkiss Brandt 81 mm Long Barrel 81 –MO-61-L (Smooth bore) for duration of acceptance tests if necessary. 2. Certificates The manufacturer shall be responsible for the performance of all inspections and tests to ensure that the bombs produced by him are fully in accordance with the specification. The manufacturer shall provide to the client when submitting a lot 11 ANNEX A of ammunition for acceptance the following certificates a. Certificate of Conformance This certificate shall state that the whole of the supplies detailed thereon have been subject to planned close control of all supply and manufacturing activities, and have been inspected and tested in accordance with this specification. It shall state: i. ii. iii. iv. The number of units of product inspected The results of inspection The number of items in the Lot The date submitted. b. Release Certificate. The release certificate of the propellant used and its manufacturer. c. Ammunition Record Sheet This certificate will consist of a detailed list of components reflecting lot numbers, date of manufacture and manufacturer’s monogram of each controlled released item used during production of the applicable batch. d. Quality Documentation All relevant quality documents of components must be supplied in English. All documents relating to the outsourcing of materials for components must be supplied in English. e. Tabular Information All relevant information in attached Table to be completed in same format (See Annex A1 attached) ii. Quality conformance inspection and tests 1. Tests to accept sub assemblies from suppliers Sampling inspections to accept sub assemblies from suppliers are to be performed on items when received from suppliers. 2. Test methods for the mortar bomb All tests conducted on 81 mm HE Mortar Bomb to be listed. Test reference standards to be listed. Tests as per MIL-STD 331 or similar acceptable standard to include a. Mechanical tests 12 ANNEX A b. c. d. e. f. g. Vibration tests Visual and Dimensional Tests Environmental & climatic Tests Safety, arming and functioning tests Static Tests Dynamic Tests i. PREPARATION FOR DELIVERY i. General On completion of all inspections and tests the ammunition shall be packed and palletised according to customer’s orders and specifications. ii. Detailed preparation 1. Preservation and packaging The packaging must consist of inner and outer containers manufactured from recyclable material that conforms to all environmental standards for the storage of ammunition. Ammunition packaging must be kept to a minimum. The packed containers must be designed for stacking on top of one another and then palletised on a wooden UN pallet (or Euro pallet). Packed containers on pallets must be capable of being stacked on top of each other to a height of three (3) meters. 2. Marking for shipment as per specification 3. Explosives classification All relevant information to be supplied IMDG Code: Ammunition UN No. Hazard Division Compatibility Group NEQ 13 - ANNEX A