[CLIENT/CUSTOMER]

advertisement

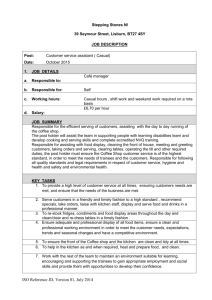

![[CLIENT/CUSTOMER]](http://s3.studylib.net/store/data/007806357_2-9fc4782574267a313620f4726d8cc5b8-768x994.png)

[CLIENT/CUSTOMER] [PROJECT] VELFAC 200 Specification [DOCUMENT REF] [REVISION] [DATE] 1. GENERAL INFORMATION / REQUIREMENTS 1.1. EVIDENCE OF PERFORMANCE. All relevant test data, technical information or other form of certification demonstrating compliance with specification will be provided upon request for CA approval. 1.2. DIMENSIONS Construction drawings will be prepared in accordance with design team details and agreed dimensions for CA approval. 1.3. CONTROL SAMPLES Section samples will be provided upon request. Any further project specific samples shall be identified and agreed for CA approval prior to instruction. 2. COMPONENTS 2.1. TIMBER / ALUMINIUM COMPOSITE WINDOWS Drawing References: [TO BE COMPLETED] Manufacturer: VELFAC LTD, The Old Livery, Hildersham, Cambridge, CB21 6DR. Telephone: 01223 897100, Facsimile: 01223 897101 Web site: www.velfac.co.uk Product reference: VELFAC 200 SERIES COMPOSITE WINDOWS. Type: Windows and window walling are to be a unitised composite aluminium/wood system, with an independent thermally isolated aluminium sash. Aluminium sash profiles will be fully ventilated and drained through concealed drainage channels and incorporate an aluminium glazing rebate. The window system will have slim 54mm external profiles and all opening and fixed lights will have consistent sightlines. Framing will facilitate the integration of concealed trickle ventilators and electrically controlled window actuators where required. All elements will be delivered fully finished with all ironmongery fitted and factory dry glazed with EPDM co-extruded single piece gaskets and internal glazing beads. Manufacture: Window production facilities will operate an ISO 9001 quality control system, and will manufacture in accordance with the technical provisions of the Danish Window Certification Scheme (DVC). Each individual window will be permanently labelled with a unique production reference concealed in the rebate of the frame to aid replacement and/or conversion and/or repair. The identification label system will form part of the manufacturing quality control and associated audit tracing. Warranty & design life: The window system will have an expected design life of at least 40 years and a schedule of maintenance will be provided. The complete window inclusive of framing, gaskets, ironmongery and glazing will be covered by a 12 year warranty from date of manufacture. Environment: Independent assessment of life cycle analysis and design life using EDIP method will be provided for CA approval. Manufacturing facilities will operate an ISO 14001 environmental policy as will key suppliers. All timber will be supplied from sustainable sources accredited under PEFC or FSC forestry management schemes and 85% of aluminium will be procured from hydro-electric sources with a recycled content of at least 50%. Page 2 of 13 Version: 106746239 3. OPENING FUNCTIONS [DELETE AS APPROPRIATE] V201 Side hung opening window Manufactured from profiles providing uniformity of sightlines across all functions. Sashes to incorporate butt hinges with number dependant upon size and weight and fitted with adjustable friction brake. Side hung windows to be independently tested and certified to BS 7950 and licensed under the Secured by Design initiative V207 Side hung projecting window Manufactured from profiles providing uniformity of sightlines across all functions. Sashes to incorporate sliding hinge blocks, steel guide rails and adjustable friction brakes to provide internal cleaning facility. V210 Fixed window Manufactured from profiles providing uniformity of sightlines across all functions. Sashes to be internally retained through concealed fixings. Fixed lights to be independently tested and certified to BS 7950 and licensed under the Secured by Design initiative V212 Top hung projecting window Manufactured from profiles providing uniformity of sightlines across all functions. Sashes mounted on steel guide rails with balance arms incorporating built in adjustable friction brake. Top hung projecting windows to be independently tested and certified to BS 7950 and licensed under the Secured by Design initiative. V220 Glass to glass corner window Manufactured from profiles providing uniformity of sightlines across all functions. Sashes to be internally retained through concealed fixings. Adjoining edges of glazing units to be stepped and fully sealed with SG18 UV resistant silicone. Cover trims bonded to the face of the glass will not be acceptable. V229 Reversible opening window Manufactured from profiles providing uniformity of sightlines across all functions. Sashes mounted on aluminium guide rails with balance arms incorporating built in adjustable friction brake and opening safety restrictor. Window to be fully reversible to facilitate internal cleaning and include automatic engagement of safety catch when placed into the cleaning position. V231 Patio window/door Manufactured from profiles providing uniformity of sightlines across all functions. Sashes to incorporate butt hinges with number dependant upon size and weight and fitted with adjustable friction brake. Window/doors to include non-skid profiled aluminium tread plates at cill [OR] low level thermally isolated profile for disabled access in accordance with Approved Document M and BS 8300. Patio window/doors to be independently tested and certified to BS 7950 and licensed under the Secured by Design initiative. Page 3 of 13 Version: 106746239 V237 Sliding window/door Manufactured from profiles providing uniformity of sightlines across all functions. In closed position, opening leaf to be flush with adjacent fixed framing and to move in an outward direction prior to sliding parallel to face of adjacent fixed frame. Sashes mounted on aluminium guide rails with nylon rollers and stainless steel control rods. Doors to incorporate concealed 6 point locking system with secure night vent provision operated by 2 number espagnolette handles and anti-lift facility all in accordance with the recommendations of the Secured by Design initiative. V200 Fire Windows Manufactured from profiles providing uniformity of sightlines across all functions and to be visually identical to adjacent elements. Windows to be tested to BS EN 1363-1, BS EN 1363-2, BS EN 1364-1 and provide class E60 (integrity) fire resistance in the following functions: [DELETE AS APPROPRIATE] V250 Fixed window V251 Side hung opening window V272 Top hung projecting window V279 Reversible opening window V261 Fire Window/doors Manufactured from profiles providing uniformity of sightlines across all functions and to be visually identical to adjacent elements. Window/doors to be tested to BS EN 1363-1, BS EN 1363-2, BS EN 1634-1 and provide class E30 (integrity) fire resistance. V210 Ventilated Fire Panel Manufactured from profiles providing uniformity of sightlines across all functions and to be visually identical to adjacent elements. Window/doors to be tested to BS EN 1363-1, BS EN 1363-2, BS EN 1634-1 and provide class EI60 (integrity & insulation) fire resistance. V200 Smoke Ventilators Manufactured from profiles providing uniformity of sightlines across all functions and to be visually identical to adjacent elements. Windows to be tested certified and CE marked in accordance with BS EN 12101-2 and a Certificate of Conformity is to be issued in accordance with the Construction Products Directive. Smoke Ventilators are to be provided in the following functions: [DELETE AS APPROPRIATE] V201 Side hung window V208 Top hung window V207 Side hung projecting window V212 Top hung projecting window V229 Reversible opening window Page 4 of 13 Version: 106746239 4. MATERIALS 4.1. INTERNAL FRAMING: North European Pine (Pinus Sylvestris), density 500kg/m 3 measured at 12% moisture content. Permissible moisture content between 9% and 15%, typically 84% of material will have a moisture content of 12% +/- 2% measured in accordance with BS EN 14220: 2006. Growth rate will not exceed 4mm when determined in accordance with BS EN 1310: 1997 4.1.1. Timber quality: Timber will be graded according to INSTA 142 and meet the requirements of category T3 in accordance with BS EN 14081: 2005, and strength class C30 in accordance with BS EN 1912: 2004. An auditable quality control system should be in place to ensure material consistency. Timber sections will be independently tested and assessed in accordance with EN 384 to identify characteristic bending strength an mean E values. Frame joint arrangements will be independently tested and assessed in accordance with EN 380 to identify loading capacities. Design of the structural timber framing will be in accordance with BS 5268: 2002. 4.1.2. Construction: Frames/mullions/transoms will be constructed from three to six laminates dependant upon the section. Frame dimensions: 50 x 90 mm and/or 50 x 115 mm 4.1.3. Sourcing All timber will be supplied from sustainable sources accredited under PEFC or FSC forestry management schemes. 4.1.4. Finish: VACUMAT preservative treated and factory finished with two coats of solvent free, micro-porous clear lacquer or acrylic paint containing anti-mould fungicide, in accordance with EN 152-1:1998. Dipped, brushed or site applied finishes will not be acceptable. Minimum dry film thickness: 100 – 225 microns. Colour: [TO BE COMPLETED] to gloss level 20% 4.2. EXTERNAL SASH: Extruded aluminium profiles in accordance with BS EN 755-2 (mechanical properties), BS EN 12020-2 & BS EN 755-9 (dimensional accuracy). Alloys: EN AW-6060 T5, EN AW-6063 T5, EN AW-6082, EN AW-6005 Dimensions: 54 mm face dimension. 4.2.1. Finish: Polyester powder coat in compliance with BS EN 6496, BS EN 6497, & DIN 50939 with applicators to be registered under the European Qualicoat and/or GSB quality assurance schemes. Minimum dry film thickness: 60–120 microns Colour: [TO BE COMPLETED] to gloss level 77%. [OR] Page 5 of 13 Version: 106746239 Finish: Anodised finishes in accordance with BS EN 12373. Anodizing pre-treatment E6 in accordance with BS EN 12373 Part 1: 2001 Table B.1. Anodic oxidation coating thickness Class 20 according to BS EN 12373-1:2001 with minimum average thickness of 20 microns and minimum local thickness of 16 microns. Light reflectance in accordance with BS EN 12373-11/12/13/14 with gloss level 12% ±5% Comparative fastness to ultra violet light and heat in accordance with BS EN 12373 Part 8. Visible defects in accordance with BS EN 12373 Part 1: 2001 with no visible defects on significant surfaces when viewed from a distance of 5m in daylight. Anodising colour reference: [TO BE COMPLETED]. 5. IRONMONGERY/ACCESSORIES 5.1. LOCKING SYSTEM 5.1.1. Concealed espagnolette multipoint locking system operated by a single handle per sash (or two handles per sliding window/door). Locking points to incorporate anti-tamper locking pins on espagnolette bolts and double stage keeps providing secure night ventilation. 5.1.2. Handles to be a matt chrome finish and are non-locking [OR] and include an integrated child safety button [OR] and include integrated key locking facility where applicable. 5.1.3. Concealed opening restrictors incorporating a socket key release mechanism providing an approximate clear opening of 100mm [OR] 210mm. 5.2. VENTILATION 5.2.1. Background ventilators: Externally concealed trickle ventilators will be incorporated into the framing sections to provide a free area of 4000mm 2. Equivalent free areas will be tested in accordance with BS EN 13141-1: 2004 and will provide 2418mm 2 when ventilators are placed in the frame head and 2800mm2 when ventilators are placed in the frame jamb. The windows will be marked with the equivalent area (EA) of each background ventilator. Over frame, glazed in or canopy ventilators will not be acceptable. 5.2.2. Automated windows: Electrically controlled opening sashes via fully concealed, 24 volt factory fitted chain actuators. Actuators must be analogous with window system and equivalent to window size with closing forces coordinated to provide gasket life protection. Actuators to be programmable to individual requirements for operational speed, sound level, traction force and reverse function to protect from over compression of window seals. Where multiple actuators are placed within one opening window they shall be fully synchronised through direct communication to ensure that no adverse forces are applied to the window system resulting in twist or racking of the opening sash. Surface mounted actuators will not be acceptable. Actuator model reference: [TO BE COMPLETED] Chain stroke: [TO BE COMPLETED] 5.2.3. Smoke ventilators: Where automated smoke ventilators are required, the complete system (i.e. window, actuator and control unit) will be tested in accordance with BS EN 12101-2: 2003 and CE marked with appropriate performance level. A Certificate of Conformity and the aerodynamic free area (Aa) of each window will be provided for CA approval. Actuator model reference: WMX 827 [OR] WMX 927 [OR] WMX 27m Chain stroke: 500mm to provide 440mm clear opening Page 6 of 13 Version: 106746239 6. GLAZING 6.1. VISION GLAZING 6.1.1. General: Windows will be delivered to site pre-glazed with insulating glass units conforming to: BS 952: 1995: Glass for Glazing – Part 1: Classification BS EN 572: 2004: Glass in building – Basic soda lime silicate glass products – Part 2: Float glass BS EN 12150: 2000: Glass in building – Thermally toughened soda lime silicate safety glass – Part 1: definition and description BS EN ISO 12543: 1998: Glass in building – Laminated safety glass BS EN 12600: 2006: Specification for Impact Performance BS EN 1279: 2002: Glass in building – Insulating glass units BS 6262: 1982: Code of practice for glazing for buildings BS 6262: 2005: Glazing for buildings – Part 4: Code of practice for safety related to human impact BS 6206: 1981: Specification for impact performance requirements for flat safety glass and safety plastics for use in buildings BS EN 6180: 1999: Barriers in and about buildings – Code of practice 6.2. VISION GLAZING: [ADD AS APPROPRIATE] Type: [TO BE COMPLETED] Inner pane: [TO BE COMPLETED] Cavity: [TO BE COMPLETED] Outer pane: [TO BE COMPLETED] Centre pane thermal transmittance (U-value) calculated in accordance with BS EN 673: 1998: not exceeding [TO BE COMPLETED] W/m2K Spectrophotometric data in accordance with BS EN 410: Glass in building – Determination of luminous and solar characteristics of glazing Total solar energy transmission of normal incident solar radiation (maximum G-value): [TO BE COMPLETED] Total light transmission (minimum LT-value):[TO BE COMPLETED] Weighted sound reduction index (Rw) within 100 to 3150 Hz frequency range to BS EN ISO 717-3 (BS EN 5821-3) between internal and external surfaces of window (minimum): Rw [TO BE COMPLETED] [OR] Individual frequency responses as detailed below [ADD FREQUENCY RESPONSES] Location Page 7 of 13 Rw C:Ctr 63 125 250 500 1000 2000 4000 Version: 106746239 6.3. NON-VISION GLAZING [DELETE AS APPROPRIATE] Type: VELFAC Ventilated enamel glass panel External material: 6mm toughened enamelled glass External glass colour: [TO BE COMPLETED] Spacer & cavity: Fully ventilated cavity with vacuum impregnated timber spacer profiles. Internal material: 9mm glass-fibre reinforced, humidity proof and diffusion open paper covered plaster board Loose fill insulation: Insulation to be provided by window installer. Internal facing board: Chipboard manufactured in accordance with BS EN 312 and class E1 according to BS EN 120 with formaldehyde content of less than 7 milligram per 100 gram of board. Board to include integral vapour barrier and to be mounted with concealed clips. Face fixed boards and visible fixings will not be acceptable. Internal finish: RAL [TO BE COMPLETED] to match frames [OR] vertically grained pine veneer Type: VELFAC Ventilated aluminium panel External material: Aluminium sheet in compliance with EN AW-1055 or EN AW-1050 for polyester powder coating [OR] Aluminium sheet in compliance with EN AW-5005 for anodising. External finish: Polyester powder coat in compliance with BS EN 6496, BS EN 6497, & DIN 50939 with applicators to be registered under the European Qualicoat and/or GSB quality assurance schemes. Polyester powder coat minimum dry film thickness: 60 – 120 microns [OR] Anodising in accordance with EN 12373. External colour: RAL [TO BE COMPLETED] to gloss level 77% [OR] Anodising colour reference: [TO BE COMPLETED] gloss level 12% Spacer & cavity: Fully ventilated cavity with vacuum impregnated timber spacer profiles. Internal material: 9mm glass-fibre reinforced, humidity proof and diffusion open paper covered plaster board Loose fill insulation: Insulation to be provided by window installer. Internal facing board: Chipboard manufactured in accordance with BS EN 312 and class E1 according to BS EN 120 with formaldehyde content of less than 7 milligram per 100 gram of board. Board to include integral vapour barrier and to be mounted with concealed clips. Face fixed boards and visible fixings will not be acceptable Internal finish: RAL [TO BE COMPLETED] to match frames [OR] vertically grained pine veneer Page 8 of 13 Version: 106746239 Type: VELFAC V280 Rainscreen Panel External material: Aluminium sheet in compliance with EN AW-1055 or EN AW-1050 for polyester powder coating [OR] Aluminium sheet in compliance with EN AW-5005 for anodising. External finish: Polyester powder coat in compliance with BS EN 6496, BS EN 6497, & DIN 50939 with applicators to be registered under the European Qualicoat and/or GSB quality assurance schemes. Polyester powder coat minimum dry film thickness: 60 – 120 microns [OR] Anodising in accordance with EN 12373. External colour: RAL [TO BE COMPLETED] to gloss level 77% [OR] Anodising colour reference: [TO BE COMPLETED] gloss level 12% Intermediate material: Weather tight cement bound woodchip board consisting of 30% Wood and 70 % cement fixed and sealed to timber mainframe. Loose fill insulation: Insulation with to be provided by window installer. Internal facing board: Chipboard manufactured in accordance with BS EN 312 and class E1 according to BS EN 120 with formaldehyde content of less than 7 milligram per 100 gram of board. Board to include integral vapour barrier and to be mounted with concealed clips. Face fixed boards and visible fixings will not be acceptable Internal finish: RAL [TO BE COMPLETED] to match frames [OR] vertically grained pine veneer Type: VELFAC PPC aluminium sandwich panel External & internal material: Aluminium sheet in compliance with EN AW-1055 or EN AW-1050 for polyester powder coating. Core insulation: Polyurethane board with core density of 39.8 – 41.2kg/m3. External & internal finish: Polyester powder coat in compliance with BS EN 6496, BS EN 6497, & DIN 50939 with applicators to be registered under the European Qualicoat and/or GSB quality assurance schemes. Polyester powder coat minimum dry film thickness: 60 – 120 microns. External colour: RAL [TO BE COMPLETED] to gloss level 77%. Internal colour: RAL [TO BE COMPLETED] to gloss level 77%. Type: VELFAC Anodised aluminium sandwich panel External material: Aluminium sheet in compliance with EN AW-5005 for anodising. Internal Material: Aluminium sheet in compliance with EN AW-1055 or EN AW-1050 for polyester powder coating. Core insulation: Polyurethane board with core density of 39.8 – 41.2kg/m3. External finish: Anodising in compliance with EN 12373. Internal finish: Polyester powder coat in compliance with BS EN 6496, BS EN 6497, & DIN 50939 with applicators to be registered under the European Qualicoat and/or GSB quality assurance schemes. Polyester powder coat minimum dry film thickness: 60 – 120 microns. External colour: Anodising colour reference: [TO BE COMPLETED] gloss level 12% Internal colour: RAL [TO BE COMPLETED] to gloss level 77%. Page 9 of 13 Version: 106746239 Type: VELFAC Cedar panel: External material: Diffusion open, water resistant plywood panel clad with Western Redwood Cedar tongue and groove horizontal slats glued and fixed with concealed screws. External finish: Western Redwood Cedar is supplied untreated and naturally weathers. Loose fill insulation: Insulation to be provided by window installer. Internal facing board: Chipboard manufactured in accordance with BS EN 312 and class E1 according to BS EN 120 with formaldehyde content of less than 7 milligram per 100 gram of board. Board to include integral vapour barrier and to be mounted with concealed clips. Face fixed boards and visible fixings will not be acceptable Internal finish: RAL [TO BE COMPLETED] to match frames [OR] vertically grained pine veneer Type: VELFAC Architectural louvre panel Material: Extruded aluminium alloy profiles in accordance with BS EN 755-2 (mechanical properties), BS EN 12020-2 & BS EN 755-9 (dimensional accuracy). Alloys: EN AW-6060 T5, EN AW-6063 T5, EN AW-6082, EN AW-6005 External finish: Polyester powder coat in compliance with BS EN 6496, BS EN 6497, & DIN 50939 with applicators to be registered under the European Qualicoat and/or GSB quality assurance schemes. Polyester powder coat minimum dry film thickness: 60 – 120 microns [OR] Anodising in accordance with EN 12373. External colour: RAL [TO BE COMPLETED] to gloss level 77% [OR] Anodising colour reference: [TO BE COMPLETED] gloss level 12% Other requirements: Insect mesh to be incorporated within perimeter framing directly behind louvre blades. [OPTIONS – DELETE AS NECESSARY] Intermediate blanking plate: Weather tight cement bound woodchip board consisting of 30% Wood and 70% cement fixed to timber mainframe. Internal facing board: Chipboard manufactured in accordance with BS EN 312 and class E1 according to BS EN 120 with formaldehyde content of less than 7 milligram per 100 gram of board. Board to include integral vapour barrier and to be mounted with concealed clips. Face fixed boards and visible fixings will not be acceptable Internal finish: RAL [TO BE COMPLETED] to match frames [OR] vertically grained pine veneer 7. PERFORMANCE 7.1. WEATHERTIGHTNESS: To BS 6375 Part 1: 2004 Exposure category: 1600 Pa Air permeability: Tested to 600 Pa in accordance with BS EN 1026: Class 4 to BS EN 12207 Watertightness: Tested to 1500 Pa in accordance with BS EN 1027: Class E1500 to BS EN 12208 Resistance to wind: Tested to 1600 Pa in accordance with BS EN 12211: Class A4 to BS EN 12210 – 1600 Pa wind serviceability / 2400 Pa wind safety Page 10 of 13 Version: 106746239 7.2. INTEGRITY: 7.2.1. Window installation shall resist the specified wind loads, dead loads and design live loads, and accommodate deflections and movements without damage. 7.2.2. Design wind pressure: Calculated in accordance with BS 6399-2: 1997 either on the following statistical factors or the design wind pressure, both provided by the CA Consulting Engineer. The windows shall accommodate the specified structural deflections and applied environmental loads with no deformation or damage. Wind loading assessments and/or formal calculations by a chartered engineer will be provided for CA inspection. Basic wind speed (Vb): [TO BE COMPLETED] Altitude factor (Sa): [TO BE COMPLETED] Direction factor (Sd): [TO BE COMPLETED] Seasonal factor (Ss): [TO BE COMPLETED] Probability factor (Sp): [TO BE COMPLETED] Terrain and building factor (Sb): [TO BE COMPLETED] Size effect factor (Ca): [TO BE COMPLETED] External pressure coefficients (Cpe): -1.3 (unless otherwise advised) Internal pressure coefficients (Cpi): 0.2 (unless otherwise advised) Design wind pressure: [TO BE COMPLETED] 7.2.3. Permanent imposed loads: No permanent loads to be transmitted to windows 7.2.4. Temporary imposed loads: Static 500 N load applied horizontally through a square of 100mm sides arising from maintenance 7.3. THERMAL PROPERTIES: 7.3.1. The window system shall be tested in accordance with BS EN ISO 10077-2: 2003. All thermal data and calculations supplied must be for the complete window units. Centre pane U-values for insulating glazing units alone will not be acceptable. A thermal data sheet must be supplied to detail all individual U-values for each window type, and a weighted average U-value for all units within the same order for CA approval. 7.4. ACOUSTIC PERFORMANCE: 7.4.1. The complete window system including the specified glazing will be tested in accordance with BS EN ISO 140-3: 1995 (BS 2750-3: 1995). All acoustic data supplied must be for complete window units, not the insulating glazing units alone. Full acoustic test reports must be supplied where appropriate for CA approval. Weighted sound reduction index (Rw) within 100 to 3150 Hz frequency range to BS EN ISO 717-3 (BS EN 5821-3) between internal and external surfaces of window (minimum): Rw: [TO BE COMPLETED] Page 11 of 13 Version: 106746239 7.5. SECURITY: 7.5.1. The window system will be tested to BS 7950: 1997 and independently certified to the requirements of Secured by Design through accredited factory audits and shall be registered as a licensed product. The following window operations will conform: [DELETE AS NECESSARY] V201 Side hung window V210 Fixed window V212 Top hung projecting window V231 Patio window/door (single leaf) 8. INSTALLATION 8.1. FRAME REINFORCING Mild steel frame reinforcement sections to relevant sections of BS 7668, BS EN 10029, BS EN 10113, BS EN 10137, BS EN 10155, BS EN 10210. Protective coating: Hot dip galvanised to BS EN ISO 1461 Dimensions: To be sized according to environmental loads in accordance with VELFAC structural assessment and/or calculations. 8.2. PROTECTION OF COMPONENTS General: Do not deliver to site components that cannot be installed immediately or placed in clean, dry floored and covered storage. Stored components: Factory packed vertically or near vertically on wooden pallets, separated with spacers to prevent damage, all pallets to be shrink-wrapped, referenced and labelled prior to dispatch from factory. 8.3. BUILDING IN Not permitted unless indicated on drawings. 8.4. WINDOW INSTALLATION GENERALLY Installation: Install windows into suitably prepared openings, maintaining a clearance of 15 mm (+0 / 5mm) between the frame edge and the surrounding construction. Distortion: Install windows without twist or diagonal racking. Accuracy of installation: ± 2mm for adjoining windows limited to ± 5mm from notional datum/position on all axis. 8.5. DAMP PROOF COURSES IN PREPARED OPENINGS Location: Ensure correct positioning in relation to window frames. Do not displace during fixing operations. 8.6. FIXING OF COMPOSITE FRAMES Spacing: Position fasteners strictly in accordance with VELFAC installation guide unless specifically indicated otherwise on VELFAC construction issue drawings. Page 12 of 13 Version: 106746239 8.7. SEALANT JOINTS 8.7.1. External Sealant: Apply pre-compressed external sealant tape immediately following frame installation in accordance with the manufacturer’s recommendations. The seal is applied to the timber frame perimeter behind the aluminium sash to provide UV protection. The use of sealant placed in the outermost plane of the windows/screens in order to seal between units and/or other adjacent materials will be unacceptable. External seal manufacturer: Tremco Illbruck Product reference: Compriband 600 certified under BBA 96/3309 Type: Mimimum 20mm depth – width to suit finished joint. Colour: Black. [OR] External Sealant: Apply silicone seal immediately following frame installation in accordance with the manufacturer’s recommendations. The seal is applied to the timber frame perimeter behind the aluminium sash to provide UV protection. The use of sealant placed in the outermost plane of the windows/screens in order to seal between units and/or other adjacent materials will be unacceptable. Ensure all surfaces are clean, dry and free from contamination and prepare the joint using an approved cleaning wipe. Insert closed cell, cross-linked, foam polyethylene backing rod or bond breaker tape to provide a seal width/depth ratio of 2:1 limited to minimum 6mm deep. Solidly fill the joint and tool to finish. External seal manufacturer: Adshead Ratcliffe Product reference: ARBOSIL 1090 Type: Low modulus one part silicone sealant, Type A in accordance with BS 5889 Colour: black. 8.7.2. Internal seal: Apply silicone seal immediately following frame installation in accordance with the manufacturer’s recommendations. Ensure all surfaces are clean, dry and free from contamination and prepare the joint using an approved cleaning wipe. Insert closed cell, cross-linked, foam polyethylene backing rod or bond breaker tape as required and solidly fill the joint and tool to finish. Internal seal manufacturer: Adshead Ratcliffe Product reference: ARBOSIL 1090 or ARBOSIL LM according to colour Type: Low modulus one part silicone sealant, Type A in accordance with BS 5889 Colour: To match or compliment window frames 8.8. IRONMONGERY Ironmongery selected from VELFAC standard range of components. Fixing: All ironmongery fitted to frames prior to dispatch from factory. Checking/ Adjusting/ Lubricating: Carry out at completion and ensure correct functioning. Page 13 of 13 Version: 106746239