Production Design & Engineering Course Outline

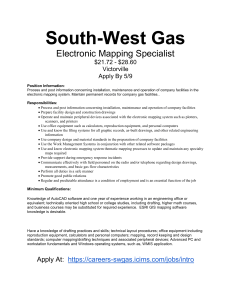

advertisement

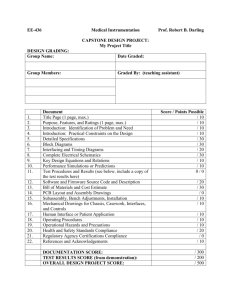

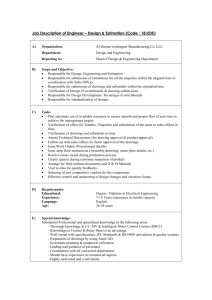

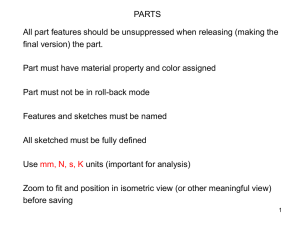

COURSE IDENTIFICATION COURSE TITLE: Production Design & Engineering PREFIX NO. MDR 1264 SEMESTER CREDIT HOURS: LCHS 1 and WITCC 3 . LECTURE CONTACT HOURS LAB CONTACT HRS OTHER (e.g., coop, clinical) Per Term: Per Term: Specify: ___________ Hours Per Term: . DEPARTMENT: Manufacturing & Engineering Technology (Instructor) Bill Dalton OFFICE LOCATION: C15 OFFICE PHONE : (712) 546-4153 OFFICE HOURS : 8:00 AM – 4:00 PM COURSE DESCRIPTION & PRE-REQUISITES / CO-REQUISITES: In a combined lab and lecture environment the student will explore practices and techniques used in today’s competitive production and manufacturing environments. Students will develop skills in Computer Assisted design using 3DModeling “Inventor” software to design and develop a project. Examples of projects will be remote control car parts and assembles, and weight lifting machines. Teaming will be used to complete part assemblies of the above projects. Students will be exposed to manual and automation systems. Student will see their part drawings printed on WITCC 3d model printer. PREREQUSITE: None COURSE NEED STATEMENT: REQUIRED TEXTBOOKS AND / OR MATERIALS: Title: None Edition: Author: Publisher: MATERIALS: . ISBN: COURSE OBJECTIVES: Upon completion of this course, the student will be able to: 1. 2. 3. 4. 5. 6. 7. 8. 9. Use Inventor commands as tools for creating Solid model drawings. Plot drawings in paper and using WITCC 3d model printer Create part drawings using Inventor. Create assembly drawings using inventor. Create 2 drawings (front, side, top, sectional and isometric drawing using Inventor. Dimension drawings using Inventor. Add annotation to drawings and balloon notes to Inventor drawings. Create avi (Media Player) presentation from part assemblies in Inventor Create a project (weight lifting machine) with a team of students using Inventor. COMPETENCIES: Knowing/Performance Use geometry constraints (add geometry constraints to control sketches). Use dimensions to control sketches. Model and edit parts from sketched features (extrude and revolve geometry). Create sketched, placed, and work features (creating drilled holes and threads). Generate 2d drawings from 3d part files (Create sheets, borders, and title blocks, create custom title blocks and templates, create standard view ports of part files, create and edit 2d drawing dimensions. Create assembly files from 3D part files (place the first base instance, redefine the default isometric view, place instances of other existing part files, create and edit assembly constraints-insert-mate-tangent- and angle constraints, toggle degrees of freedom icons on and off, simulate assemblies-drag part instances to test constraints. Model parts inside assembly files (design parts using geometry in other parts, build in design clearance between parts, analyze assemblies to find interference between parts, measure distances and angles). Presenting your 3D designs (Creating new presentation files-use templates to create new presentations, create exploded assembly views, animate exploded views to create animation re-assemble parts, record animations into avi files). Create assembly drawings (generate drawing views of assemblies, generate bill of materials-create and edit part lists, create individual balloons, define custom parts by assigning custom parts to a parts list, and generate section views of a part file). AMERICANS WITH DISABILITIES ACE (ADA) If you have a disability, please feel free to set up an appointment with the instructor to discuss “reasonable” accommodations, which might be of assistance. For additional information and/or assistance, contact the Student Success Center in the Dr. Robert H. Kiser Building (A), Extension 1247, or any of the extended campuses at Cherokee (Extension 1240) or Denison (Extension 1458). Manufacturing Technologies.-DUAL CREDIT (No Textbook required) Credits: 1 LCHS- 3 WITCC Elective/Required: Elective Prerequiste: Production Design & Engineering Grade Level: 10,11,12 In a combined lab and lecture environment the student will explore practices and techniques used in today’s competitive production and manufacturing environments. Students will design a product using “Inventor” software in teams and use CAD\CAM CNC Lathe and Milling machines to bring their part from design to the end process. Teaming will be used to complete part assemblies of the above projects. Students will be exposed to fundamental of automation with controls and sensors, manual mechanisms, fluid power, electricity and electronics in manual and automated systems.