Industrial Technology and Design Activity

advertisement

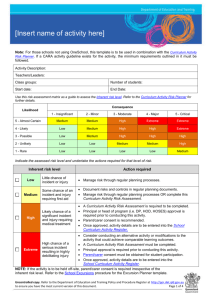

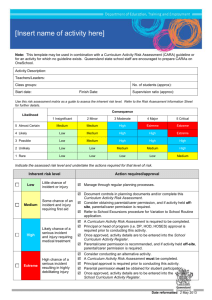

Industrial Technology and Design Activity Activity Scope* *Due to the complex nature of ITD activities, additional sections can be completed on this word document and uploaded to OneSchool as an attachment. This Industrial Technology and Design (ITD) Activity Curriculum Activity Risk Assessment (CARA) has been designed to document the risk assessment of specific ITD practical activities, where several key elements (e.g. plant and equipment, hazardous materials and manufacturing processes) have the potential to expose staff and students to foreseeable hazards and risks. Note: This risk assessment document is a guideline, and should be prepared in conjunction with the ITD CARA Managing a Practical ITD Workspace. Depending on the nature of the activity, you may need to also consider CARAs completed for other ITD activities and equipment such as: Chemical Hazards in the Curriculum, Compressed Air Equipment, Electrics and Electronics, Fixed Machines, Mechanics, Metalworking, Plastics, Fibre Reinforced/Composites or Plastics, Thermoforming, Portable Electric Power Tools, Soft Soldering, Spray Painting, Welding, Electric Arc or Welding, Gas Heating and Cutting, or Woodworking. The key elements of an ITD activity might include: the use of machinery, power tools and construction materials physical exertion or manual handling manipulating and processing construction materials through the fabrication of artefacts the use of, and exposure to, chemicals, vapours and wood dusts changeable workspace environments the use of electrical power (both AC and DC or 3-phase) ITD Activity description Student at workshop © Education Queensland Date modified: 30 January 2014 Overall Risk Level calculator The overall risk level for a specific ITD activity will equate to the highest risk level of any key elements identified. 1. Identify and list the key elements associated with the delivery of this ITD activity. 2. Indicate if your school has previously completed and approved a risk assessment document for each item of plant and equipment listed, for all hazardous materials listed, and for any other ITD CARAs incorporated within this specific 'ITD Activity' CARA. 3. Indicate the Risk Levels (e.g. L=Low, M=Medium, H=High, E=Extreme) previously determined for each assessment listed (as documented by your school). 4. Indicate if a 'Safe Operating Procedure' (SOP) is displayed on or near any potentially hazardous machinery, equipment or portable power tool to be used in the delivery of this activity. ITD Activity – Overall Risk Level SOPs Displayed Assessment Risk Level 5. Details (optional) 4. Give a brief description of each element of the activity 3. Equipment, Materials and Processes 2. 1. Approved Risk Assessment 5. Then you may give a brief description of each key element listed. Note: The overall risk level will equate to the highest risk level of any key element listed. Uncontrolled when printed Industrial Technology and Design Activity — Page 2 of 4 Inherent Risk Level When considering the inherent level of risk associated with this specific ITD activity, consider the following: a) the nature of the intended activity b) the participants involved c) the machinery, tools and hazardous materials to be used d) the environment in which the activity is occurring. Ask yourself: Which groups of students would normally be involved? Who will be planning and leading this activity? Will extra supervision and support be required? Are there specifically designed ITD workspaces? Are all emergency management procedures in place? Are all SOPs available and prominently displayed? What plant and machinery or power tools would normally be used by students in the delivery of this activity? Have plant risk assessments been completed (and remain current) for high to extreme risk machinery and power tools? Have hazardous substance risk assessments been completed (and remain current) for any toxic materials, glues, solvents, oils, paints or potentially dangerous gases likely to be used? Minimum activity-specific qualifications for supervisors A registered ITD teacher with demonstrated competency and ability to undertake this activity (e.g. as documented in an ITD staff profile), OR A registered teacher with: o a related trade background and formal trade qualifications, OR o certified training in a course directly related to this activity and recognised experience working in an ITD practical workspace, OR A leader other than a registered teacher with expertise (formal trade qualifications) in a trade where appropriate practical workshop skills were a component of the trade qualifications. Note: Under these circumstances, a registered ITD teacher must take overall responsibility for this activity. Activity-specific equipment/facilities Completed Curriculum Activity Risk Assessment for Managing a Practical ITD Workspace for each practical workspace or classroom to be utilised in the course of this ITD practical activity. Any other relevant completed Curriculum Activity Risk Assessments. Activity-specific hazards/risks and suggested control measures Ensure the Curriculum Activity Risk Assessment for Managing a Practical ITD Workspace is adhered to. Ensure that any other completed CARAs relevant to this activity are adhered to. Ensure there is adequate adult supervision. Student numbers should be determined by the risk of the activity, space available, tools and equipment used, ability of students, and experience of the teacher. Ensure student “Workplace Safety Induction” is managed and documented (e.g. a licensing process). Useful activity-specific links Chemical Hazards in the Curriculum – Curriculum Activity Risk Assessment guideline http://education.qld.gov.au/curriculum/carmg/doc/chemical-hazards-template.doc Chemical Hazards Guidance Notes http://education.qld.gov.au/curriculum/carmg/doc/guidance-notes.doc Compressed Air Equipment – Curriculum Activity Risk Assessment guideline http://education.qld.gov.au/curriculum/carmg/pdf/compressed-air-equip.pdf Uncontrolled when printed Industrial Technology and Design Activity — Page 3 of 4 Electrics and Electronics – Curriculum Activity Risk Assessment guideline http://education.qld.gov.au/curriculum/carmg/pdf/electrics-and-electronics.pdf Fixed Machines - Curriculum Activity Risk Assessment guideline http://education.qld.gov.au/curriculum/carmg/pdf/fixed-machines.pdf Health and Safety – Hearing Protection Fact Sheet http://education.qld.gov.au/health/pdfs/healthsafety/hearing-protection-factsheet.pdf ITD Plant/Equipment Resources for Education Queensland sites http://education.qld.gov.au/health/safety/hazards/equip-resources.html#sop Managing a Practical ITD Workspace – Curriculum Activity Risk Assessment guideline http://education.qld.gov.au/curriculum/carmg/pdf/managing-practical-itd-workspace.pdf Managing Noise and Preventing Hearing Loss at Work – Code of Practice 2011 http://www.deir.qld.gov.au/workplace/resources/pdfs/noise-preventing-hearing-loss-cop-2011.pdf Mechanics – Curriculum Activity Risk Assessment guideline http://education.qld.gov.au/curriculum/carmg/pdf/mechanics.pdf Metalworking – Curriculum Activity Risk Assessment guideline http://education.qld.gov.au/curriculum/carmg/pdf/metalworking.pdf Plastics, Fibre Reinforced/Composites – Curriculum Activity Risk Assessment guideline http://education.qld.gov.au/curriculum/carmg/pdf/plastics-fibre-reinforced.pdf Plastics, Thermoforming – Curriculum Activity Risk Assessment guideline http://education.qld.gov.au/curriculum/carmg/pdf/plastics-thermoforming.pdf Portable Electric Power Tools – Curriculum Activity Risk Assessment guideline http://education.qld.gov.au/curriculum/carmg/pdf/portable-electric-tools.pdf Soft Soldering – Curriculum Activity Risk Assessment guideline http://education.qld.gov.au/curriculum/carmg/pdf/soft-soldering.pdf Spray Painting – Curriculum Activity Risk Assessment guideline http://education.qld.gov.au/curriculum/carmg/pdf/spray-painting.pdf Welding, Electric Arc – Curriculum Activity Risk Assessment guideline http://education.qld.gov.au/curriculum/carmg/pdf/welding-electric-arc.pdf Welding, Gas Heating and Cutting – Curriculum Activity Risk Assessment guideline http://education.qld.gov.au/curriculum/carmg/pdf/welding-gas-heating-cutting.pdf Woodworking – Curriculum Activity Risk Assessment guideline http://education.qld.gov.au/curriculum/carmg/pdf/woodworking.pdf Disclaimer: This document is developed and distributed on this website by the State of Queensland for use by Queensland state schools. Use or adaptation of, or reliance on, this document or information in this document by persons or organisations other than the State of Queensland is at their sole risk. All users who use, adapt or rely on this document or any information in this document are responsible for ensuring by independent verification its accuracy, currency and appropriateness to their particular circumstances. The State of Queensland makes no representations, either express or implied, as to the suitability of this document or the information in this document to a user’s particular circumstances. To the full extent permitted by law, the State of Queensland disclaims all responsibility and liability (including without limitation, liability in negligence) for all expenses, losses, damages and costs arising from the use or adaptation of, or reliance on, this document or any information in this document. Links in this document to external websites are for convenience only and the State of Queensland has not independently verified the information on the linked websites. It is the responsibility of users to make their own decisions about the accuracy, currency, reliability and correctness of the information at these external websites. Uncontrolled when printed Industrial Technology and Design Activity — Page 4 of 4