Seafood Processing Plant Waste Management

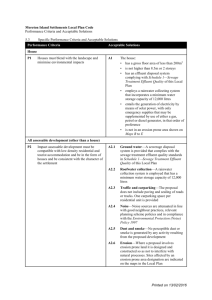

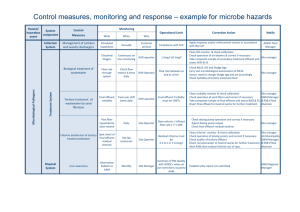

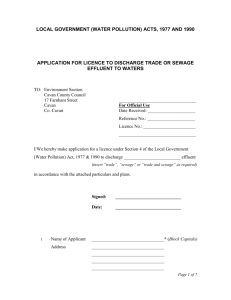

advertisement

Seafood Processing Plant Waste Management In past years, many seafood processing plants, especially those in coastal areas have disposed of their effluents in drainage systems or other convenient disposal routes without properly treating them to remove or reduce solid and organic wastes rich in nutrients. Environmental and regulatory agencies are under pressure to come up with recommendations to establish practices to monitor and treat effluents to minimize the impact of discharged wastes into the environment. One of the recommendations has been to recycle wastes, then treat them before they are released. Effluent quality would have to be measured and quantified to assure it meets industry water quality standards. Most countries are using standards proposed by the National Environmental Quality Act and CECC Directive 91-271 BE 2539 (1992). Waste water from processing is normally loaded with organic and inorganic substances to include remnants of by products, floating and suspended solids, chemicals, disinfectants and additives used in processing and often heavy concentrations of nutrients, especially nitrogen, phosphorus, sulfide and particulate organic carbon which contribute to eutrophication of the receiving waters. The objectives of a good waste disposal program for seafood processing plants should be to treat the solid waste and waste water efficiently to prevent eutrophication of waters receiving the effluent. . Principles For Waste Management at Seafood Processing Plants: Plants must be properly licensed to dispose of wastes and will be required to establish a monitoring system that is appropriate for the volume of effluent and load. The solid waste should be removed before it becomes part of the effluent and disposed of separately, preferably on land in a contained area. Monitoring and verification systems should target continuous improvements for waste reduction. If you cannot quantify and measure waste, you cannot manage it efficiently. Plants should implement Best Management Practices (BMP) to treat wastes with a goal of meeting or exceeding industry standards for the area or country involved. BMPs should include: minimizing process water by recycling when possible which would conserve water used. Solid plant wastes like byproducts of processing should be kept off the floor and removed before they become part of the effluent discharge. Effluent strength and volume can be reduced by collecting solids and inorganic wastes in catch basins and by periodic removal and disposal. Some of the more suitable primary and secondary treatment systems for effluents and industrial waste water being discharged at processing plants include: Mechanical screening of effluents to remove suspended solids. Dissolved air floatation techniques that use fine air bubbles to float and suspend solids, oil and grease. Sedimentation reservoirs or basins to remove solids by gravity settlement or through use of chemicals to flocculate suspended and colloidal solids. Aerobic and anaerobic biological treatments for removing or reducing biological oxygen demand (BOD) and chemical oxygen demand (COD) levels. Waste treatment using trickling filters and the activated sludge process promote biochemical oxidation of organic matter in waste. In many countries, the processing plants must also comply with industrial effluent standards. Some of the more important industry standards for seafood facilities are listed in Table 1. Critical effluent components for seafood processing plants include pH values, total suspended solids, BOD, total ammonia nitrogen, soluble phosphorus, objectionable odor, and fat, oil and grease levels. Table 1. A list of industrial effluent standards values and the recommended method for examination is shown in the table below: Effluent Standards Parameter Method of Examination Status ACC required standard Effluent Standard Value 6.0 - 9.5 initially and 6.0 - 9.0 after 5 years. Industrial standard is 5.5 - 9.0 Total Dissolved Solids (TDS) Industrial Standard not required by ACC * not more than 3,000 mg/l depending on receiving water or type of industry Drying/Gravimetric Analysis Total Suspended Solids (TSS) ACC required standard Initially, not more than 100 mg/l and not more than 50 mg/l after 5 year. Industry standard for wastewater treatment not to exceed 150 mg/l. Drying/Gravimetric Analysis Not more than 40ºC - no more than 3ºC rise Thermometer during sampling Not more 5.0 mg/l depending on receiving water or type of industry but not to exceed 15 mg/l Solvent Extraction by Weight pH Temperature Fat, Oil and Grease (FOG) Industrial Effluent - not required by ACC Industrial Effluent Standard under consideration by ACC pH meter Biological Oxygen Demand (BOD) ACC required standard 50 or less initially and 30 or less after 5 years. Industrial requirement is no more than 60 mg/l depending on type of industry. Azide Modification at 20ºC for five days Total Kjedahl Nitrogen (TKN) Industrial Standard not required by ACC Not more than 200 mg/l depending on receiving waters. Kjedahl Nitrogen method Chemical Oxygen Demand (COD) Industrial Standard not required by ACC Not more than 400 mg/l depending on receiving waters Potassium Dichromate Digestion Free Chlorine Industrial Standard not required by ACC Not more than 1 mg/l Iodometric method. ACC required standard Currently under evaluation Flow Injection Analysis ACC required standard Currently under evaluation Flow Injection Analysis Soluble Phosphorus Total Ammonia Nitrogen (TAN) Suggestion Regarding Processing plant Effluent sampling at processing plants Sampling should be done at select points based on the following considerations: At point of discharge of the raw effluent into the treatment system (lagoons, oxidation tanks, settling tanks, etc). At the point the treated effluent leaves the treatment facilities At the point where the discharge enters the environment (canal, river, estuary, etc). or at the point the discharge leaves the facility property (especially important if other facilities are discharging into the canal). If the effluent is being treated by an industrial park facility or some other authority is responsible for treating the effluent for your facility, you would need to show permit and name of responsible party. How to interpret samples: The BOD, total suspended solids, pH, total ammonia nitrogen reading must comply with the BAP standards either under the limits shown. Soluble phosphorus and dissolved oxygen must be shown but allowances may be made based on the treatment system and the parameter readings. However it will be on a case by case consideration depending on the treatment method. In any case, the total phosphorus readings must be taken and reported along with the volume of water discharged from the plant over a 24 hour period on the day the reading is taken. If the plant has high suspended solids in a lagoon system where the water is treated with aerators, you may need a settling pond before and after the area where the water is aerated or a settling basin (can be a serpentine canal) to allow further settling of the water. Water should always be decanted off of the surface to reduce the mixing of bottom sediments with the effluents. Sediments from the settling pond may have to be removed periodically and stored on land in contained area.