6.6.2 Use of a membrane bio-reactor (MBR) for enhanced biological

advertisement

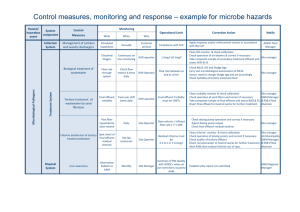

6.6.2 Use of a membrane bio-reactor (MBR) for enhanced biological effluent treatment Description MBR treatment is considered to be an emerging technique with a major potential in waste water treatment. The MBR technique is a combination of activated sludge treatment that employs membrane filtration to retain all the bio-mass in the bio-reactor. The technique ensures that a much higher solids concentration can be accommodated than with conventional biological treatment. This reduces the size of the plant compared to conventional treatment. The MBR can be fitted with a hollow fibre membrane to supply bubbles of dissolved oxygen to the biological treatment plant in a highly efficient manner. The principal reason for using this technique is to meet discharge limits by reducing suspended solids, COD, and BOD levels. The system can also reduce levels of specific substances that might be a problem, such as chromium or insecticide residues. Achieved environmental benefits The MBR technique provides a relatively compact alternative to conventional effluent treatment options, producing very little excess sludge and a high quality effluent even at high and varying organic loading rates. Substantial reductions of COD, BOD and suspended solids discharge are possible. The MBR permeate can be polished by reversed osmosis, which enables 'salt-free' water recycling. Cross-media effects No significant cross-media effects have been identified apart from a small generation of excess sludge. Applicability The technique can be applied by both new and existing installations. This technique is a secondary treatment. It is particularly relevant where discharges are direct to the aquatic environment; it is less relevant where the discharge is to sewer, that is, unless charging for external effluent treatment is based on the organic matter content. Economics According to the suppliers, the technique is a relatively low-cost process which can be successfully applied for tannery effluent treatment. In some circumstances, charges for external effluent treatment can be reduced. Driving force for implementation The main driving force for the use of the technique is the need or desire to reduce organic matter in the effluent. Status of development The technique has been used on a full-scale with success. Reference literature [102, Scholz et al. 2006].