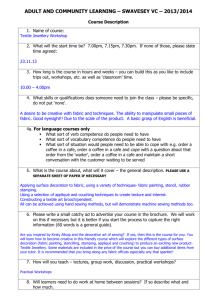

MAUI COMMUNITY COLLEGE - University of Hawai`i Maui College

advertisement

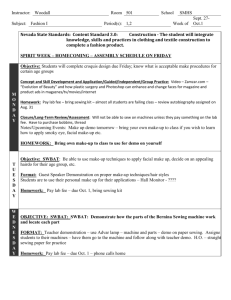

MAUI COMMUNITY COLLEGE COURSE OUTLINE 1. ALPHA & NUMBER: FT 25 COURSE TITLE: Ready-to-Wear Clothing Production NUMBER OF CREDITS: Three (3) DATE OF OUTLINE: March 8, 2004 2. COURSE DESCRIPTIONS: Explores efficient and economical techniques in fabric layout, cutting, and sewing. Offers practice in aloha shirt and blouse construction. 3. CONTACT HOURS PER WEEK: Lect./lab – Five (5) 4. PREREQUISITES: None COREQUISITES: None RECOMMENDED PREPARATION: None APPROVED BY ________________________________ DATE _______________ 5. GENERAL COURSE OBJECTIVES: To introduce students to efficient and economical industry techniques used in the production of garments, including equipment and machine attachment use, fabric layout, cutting, and sewing. 6. STUDENT LEARNER OUTCOMES: Upon completion of this course, students will be able to: a) Safely operate the industrial sewing machines and steam iron. b) Properly maintain the industrial sewing machines. c) Properly operate the industrial steam irons. d) Use the various sewing machine attachments. e) Identify the supplies, tools and notions used in sewing. f) Demonstrate an understanding of industry terminology. g) Apply mass productions techniques of marker making, laying and cutting. h) Construct garments using mass production sewing techniques. i) Demonstrate how a simple garment factory operates. 7. 8. RECOMMENDED COURSE CONTENT: A. Safety in operation of sewing machines. ( .75 hr.) B. Identification of sewing machine parts and functions. (.75 hr.) C. Operation of the sewing machine - winding bobbin, threading, backstitching, controlled handling and cleaning. Sewing and handling drill exercises. (15 hrs.) D. Solutions to machine operation problems. (1.25 hrs.) E. Operation of the steam iron. (.25 hr) F. Mass production techniques using specialty machines and attachments. (15 hrs.) Machines: serger, blind hemmer, coverstitch, sew-serge-gather, buttonholer, cutter Attachments: 1/8” roll hem foot, 1/4” roll hem foot, gathering foot, zipper foot, elastic metering attachment G. Mass production garment production -- factory set-up (47 hrs.) marker development laying fabric cutting with electric saw project construction – created to use specific techniques, machines and attachments --tote bag --drawstring pant --knit skirt with satin binding --button down aloha shirt --tab front aloha shirt --night shirt RECOMMENDED COURSE REQUIREMENTS Specific course requirements are at the discretion of the instructor. Suggested requirements might include, but are not limited to: Student projects Machine attachment and sewing techniques notebook Sewing machine competency Stitching and handling drill exercises FINAL Project Meeting deadlines and overall performance 9. TEXT/MATERIALS/SUPPLIES: Text: No text required Text may be supplemented with: Instructor handouts Oaktag patterns for demonstration samples and garments Videos--How Clothing is Made Lab supplies: Production patterns in standard sizes for all projects Marking paper Students supplies: 8” shears eraser fabric marking tool 12” C-thru ruler fabric for all projects 10. 11. EVALUATION/GRADING: Student Projects Machine attachment and sewing techniques notebook Sewing machine competency Stitching and handling drill exercises FINAL Project Meeting deadlines and overall performance METHODS OF INSTRUCTION: Suggested methods might include, but are not limited to: Lecture Demonstrations Class discussion Group work FT25 thread nippers red colored pencil 2-7” nylon zippers 3 ½ yds. muslin #2 pencil press cloth tape measure safety pins 40% 20% 15% 10% 10% 5%