Laboratory 1c - Workforce3One

advertisement

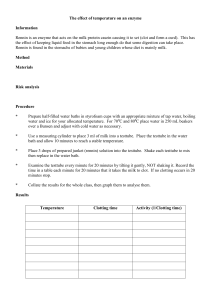

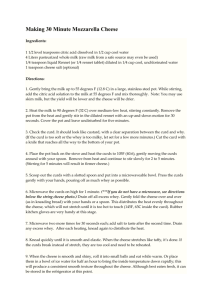

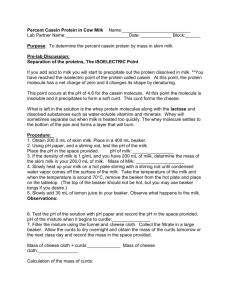

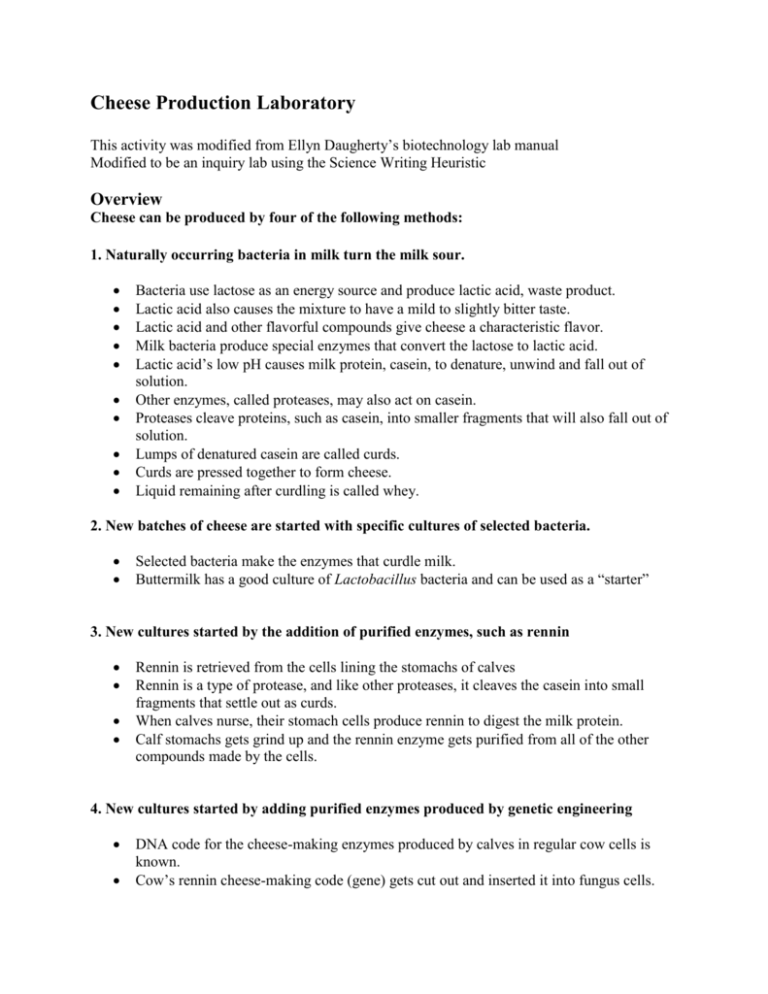

Cheese Production Laboratory This activity was modified from Ellyn Daugherty’s biotechnology lab manual Modified to be an inquiry lab using the Science Writing Heuristic Overview Cheese can be produced by four of the following methods: 1. Naturally occurring bacteria in milk turn the milk sour. Bacteria use lactose as an energy source and produce lactic acid, waste product. Lactic acid also causes the mixture to have a mild to slightly bitter taste. Lactic acid and other flavorful compounds give cheese a characteristic flavor. Milk bacteria produce special enzymes that convert the lactose to lactic acid. Lactic acid’s low pH causes milk protein, casein, to denature, unwind and fall out of solution. Other enzymes, called proteases, may also act on casein. Proteases cleave proteins, such as casein, into smaller fragments that will also fall out of solution. Lumps of denatured casein are called curds. Curds are pressed together to form cheese. Liquid remaining after curdling is called whey. 2. New batches of cheese are started with specific cultures of selected bacteria. Selected bacteria make the enzymes that curdle milk. Buttermilk has a good culture of Lactobacillus bacteria and can be used as a “starter” 3. New cultures started by the addition of purified enzymes, such as rennin Rennin is retrieved from the cells lining the stomachs of calves Rennin is a type of protease, and like other proteases, it cleaves the casein into small fragments that settle out as curds. When calves nurse, their stomach cells produce rennin to digest the milk protein. Calf stomachs gets grind up and the rennin enzyme gets purified from all of the other compounds made by the cells. 4. New cultures started by adding purified enzymes produced by genetic engineering DNA code for the cheese-making enzymes produced by calves in regular cow cells is known. Cow’s rennin cheese-making code (gene) gets cut out and inserted it into fungus cells. Fungus cells then read the cow DNA and synthesized the rennin enzyme. Recombinant Rennin is called “chymosin.” Genetically engineered enzymes are used to speed curdling. Fungal cultures produce the curdling enzymes in a faster, cheaper manner, and in larger amounts that can be produced inside big, multicellular organisms, such as cows. Procedures You will be given milk and 4 different curdling agents and your classmates must divide into groups and design your experiments. Keep in mind that a true experiment must have a control and must be rum several times To make cheese for this lab you will need 7mL of milk and 250μL of each of the curdling agents (buttermilk, rennin, and chymosin) One a particular agent is been added to the milk incubate for 15 minutes Note when curdling starts When no more curdling is produced separate whey from curds what is the best way and why? How much curds are produced? How could this be determined? Data collection Put together some form of a table with the variables that you think you will be collecting and the ones you think you might need to calculate Analysis How does your results compare with your classmates? What can be learned from the results collected? 1. Time took for curdling 2. Amount of curdles produced 3. Amount of whey produced What claim can you make concerning the different agents used to produce cheese? Use class data to put a graph together showing any trends Think about using averages for each variable when graphing why would this be helpful? Post Lab Questions Are there any anomalies in your data? What went wrong? How could you fix that? What other methods for separating cheese from whey can be used? Teachers Notes: Table put together by students must have the following features Curdling Agent Time to Curdle (min) Volume of Whey (mL) Volume of Curds (mL) Mass of Curds (g) Buttermilk Rennin Chymosin Milk (control) Chymosin produces the most amounts of curds in the shorter amount of time Rennin comes next Followed by buttermilk There should be nothing happening with the milk, control This project is funded by a grant awarded under the President’s Community Based Job Training Grant as implemented by the U.S. Department of Labor’s Employment and Training Administration (CB-15-162-06-60). NCC is an equal opportunity employer and does not discriminate on the following basis: against any individual in the United States, on the basis of race, color, religion, sex, national origin, age disability, political affiliation or belief; and against any beneficiary of programs financially assisted under Title I of the Workforce Investment Act of 1998 (WIA), on the basis of the beneficiary’s citizenship/status as a lawfully admitted immigrant authorized to work in the United States, or his or her participation in any WIA Title I-financially assisted program or activity. This product was funded by a grant awarded under the President’s High Growth Job Training Initiative, as implemented by the U.S. Department of Labor’s Employment & Training Administration. The information contained in this product was created by a grantee organization and does not necessarily reflect the official position of the U.S. Department of Labor. All references to non-governmental companies or organizations, their services, products, or resources are offered for informational purposes and should not be construed as an endorsement by the Department of Labor. This product is copyrighted by the institution that created it and is intended for individual organizational, non-commercial use only.