Core–shell structured Fe 3 O 4 @OMS

advertisement

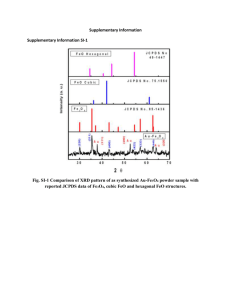

Core–shell structured Fe3O4@OMS-2 catalysts for efficient decomposition of organic dyes in aqueous solution with peroxymonosulfate 魏明瑜 1,孙彬哲 1,程龙 1,段练 1,李晓霞 2,徐爱华 1* (1. 武汉纺织大学环境工程学院 武汉 430073 2.武汉纺织大学化学与化工学院 武汉 430073) Abstract: In this study, a Fe3O4@OMS-2 core–shell nanocomposite was synthesized by a solventfree process and characterized by X-ray diffraction, Field-emission transmission electron microscope, N2 adsorption/desorption isotherms, Fourier transform infrared spectroscopy and Xray photoelectron spectroscopy (XPS), to develop a magnetically recyclable catalyst for heterogeneous activation of peroxymonosulfate (PMS) and organic dyes degradation. It was found that in this catalyst the cryptomelane-type OMS-2 shell with nanorod morphology coats closely on the Fe3O4 core, and exhibits excellent activity toward the oxidation of organic dyes in water due to the presence of mixed-valence manganese species and a large surface area. The nanocomposites can be easily recovered with the assistance of an external magnetic field and be reused for at least 8 successive cycles. The degradation mechanism and the effect of several parameters on the degradation efficiency were also discussed. Therefore, the results presented herein imply that Fe3O4@OMS-2 could be used as an effective recyclable catalyst for organic dyes degradation with PMS. Keywords: OMS-2; Fe3O4; Organic dye; Degradation; Peroxymonosulfate 1. Introduction Nanosized manganese oxides such as MnO2, Mn3O4, Mn2O3, MnO and their composites with other oxides have attracted considerable research interest as low cost, efficient, and environmentally friendly materials [1-3]. Cryptomelane-type manganese oxide octahedral molecular sieves (K-OMS1 2, KMn8O16) belong to a group of manganese oxides with a 2×2 tunnel structure formed by edge and corner sharing of manganese oxide (MnO6) octahedra, resulting in a one dimensional (1-D) channel [4,5]. Due to the salient features like porous structure, mixed-valence (2+, 3+, and 4+) of Mn species, easy release of lattice oxygen and acidic sites, the materials have been extensively investigated for diverse applications of catalytic reactions [6-17] . For example, in the liquid-phase catalytic oxidation of p-chlorotoluene to p-chlorobenzaldehyde, OMS-2 showed much higher catalytic activities than MnO2, Mn3O4, Mn(OAc)2 as well as than some other transition metal oxides such as Co2O3, V2O5 and Fe2O3. The impregnation of Ag in K-OMS-2 improved the activity of the catalyst by decreasing concentration of acidic sites and increasing basic sites for the oxidation of 5hydroxymethylfurfural to 2,5-diformylfuran [10]. In our previous work, it was also found that OMS2 showed excellent activity and stability for organic dyes decompositions in aqueous solution in the presence of peroxymonosulfate (PMS) [11]. However, the performance of the present OMS-2 catalysts still does not meet the needs of practical applications because of the inconvenience of recycling the catalysts from solution. Thus, the development of a simple and environmentally friendly strategy to prepare OMS-2 with a facile separation property is of great interest. Recently, magnetic nanoparticles in particular Fe3O4 with excellent superparamagnetism and low toxicity have been extensively applied in designing magnetically separable materials [18]. Heterostructured catalysts composed of the magnetic component, including Fe3O4@CuMgAllayered double hydroxide [19], g‑C3N4−Fe3O4 [20], Fe3O4@WO3 [21] and TiO2/Fe3O4 [22], have shown improved performance, due to their unique properties and potential applications that could not be achieved solely with a single-component catalyst. However, until now few works have been done to functionalize magnetic nanoparticles by coating them with the manganese oxides OMS-2. Zhang al. synthesized magnetic OMS-2 adsorbent and photocatalyst by grafting Fe3O4 on the surface of OMS-2 and OMS-2/TiO2 nanowires via a coprecipitation method, respectively [23, 24]. But in oxidation reactions, the external Fe3O4 nanopartials can be easily oxidized by dioxygen or other oxidants, leading the loss of superparamagnetism. On the hand, the covering of OMS-2 with Fe3O4 nanoparticles could decrease the availability of its surface reactive sites. Thus, the magnetic OMS- 2 2 with Fe3O4 as the core a ideal material with great potential to be used in oxidation reactions. In this work, a type of core–shell structured Fe3O4@OMS-2 catalysts was successfully synthesized by a solvent-free method. The as-prepared nanocomposites were structurally characterized by X-ray diffraction, FTIR spectroscopy, transmission electron microscopy, N2 adsorption/desorption isotherms and X-ray photoelectron spectroscopy. To evaluate the activity and the stability of the nanocomposite, the decomposition of Acid Orange 7 by PMS was selected as the model reaction, as heterogeneous activation of the oxidant to sulfate radical for efficient removal of organic pollutants has become an important way due to its high oxidizing ability [25-28]. 2. Experimental section 2.1 Materials The oxidant potassium peroxymonosulfate (KHSO5), derived from the triple salt, Oxone (2KHSO5·KHSO4·K2SO4, containing 47% KHSO5), and Fe3O4 nanopowder (20 nm particle size, 99.5% purity) were obtained from Aladdin Industrial Inc. Acid Orange 7 (AO7) was purchased from Aldrich. KMnO4, Mn(Ac)2•4H2O, tert-butanol (TBA), ethanol (EtOH),, Methylene Blue (MB), Reactive Brilliant Red X-3B (X-3B), Methyl Orange (MO), and Rhodamine B (RhB) from Sinapharm Chemical reagent Co., Ltd. were used without further purification. The sample solutions were prepared with deionized water (DW) throughout all the experiments. 2.2 Synthesis Fe3O4@OMS-2 was synthesized by a solvent-free method similar to that reported on the literature [29]. In a typical reaction, 9.48 g KMnO4, 22.05 g Mn(Ac)2 •4H2O and 5 g Fe3O4 powders were mixed and ground homogeneously in a mortar for 30 min. The mixed powders were then placed in a capped glass bottle and maintained at 80°C for 2 h. The resulting black product was thoroughly washed with deionized water four times to remove the remained ions, and finally dried at 80°C in air overnight. 2.3 Characterization X-ray diffraction (XRD) patterns were recorded on a Bruker D8 Advance X-Ray diffractometer for crystalline phase identification. FT-IR spectra were recorded on a Bruker 3 VERTEX 70 spectrometer. The size and morphology of the catalysts were examined by fieldemission transmission electron microscope (FETEM, Tecnai G2 F20). The magnetic properties (MH curve) were measured at room temperature on a MPMS XL-7 magnetometer made by Quantum Design Corp. The Brunauer−Emmett−Teller (BET) surface area and pore size distribution were measured by N2 adsorption and desorption at 77 K on a full-automatic multi-purpose adsorption instrument (3Flex, Micromertics). X-ray photoelectron spectra (XPS) were measured on a multifunctional imaging electron spectrometer with AlKa radiation as the exciting source. Charging effects were corrected by adjusting the binding energy of C 1s to 284.6 eV. 2.4 Organic Pollutants Degradation Degradation reactions were performed in a 100 mL open flask at ambient temperature and under normal laboratory light. The flask was putted in a shaker at a stirring speed of 150 rpm. After the desired amount of organic dye in 50 mL of the aqueous solution was added into the reactor, the reaction was initialized by adding OMS-2 and PMS. Since PMS is an acidic oxidant, the addition of PMS led to a significant decrease of pH, and the experiment was conducted at acidic medium (pH 3.84, no adjustment). For studying the effect of solution pH on the rate of AO7 degradation, H2SO4 (20 mM) and NaOH (20 mM) was used to adjust the solution pH after PMS was added into the solution. For the recycling experiment, the catalyst was separated by magnetic separation without any treatment after each recycle, and then the next reaction was started by adding a fresh solution of AO7 and PMS. To monitor the degradation process of organic dyes, solution samples were taken out at given time intervals with solid removal and measured immediately on a Varian Cary 50 Scan UV–Vis spectrophotometer. All the measurements were conducted in triplicate to ensure the reproducibility of experimental results. For the dyes AO7, KN-R, MB, RhB, X-3B and MO, their maximum absorption wavelengths are 484 nm, 592 nm, 664 nm, 555 nm, 538 nm and 464 nm, respectively. The Mn and Fe ions leaching were monitored by atomic absorption spectroscopy. 3. Results and discussion 3.1 Catalyst Characterization 4 As nano Fe3O4 is easy to dissolve in strong acid solution and highly susceptible to oxidation when exposed to the atmosphere, the preparation of Fe3O4-based magnetic nanocomposite cannot be carried out under harsh conditions such as high temperatures and low solution pH. As pure phase cryptomelane K-OMS-2 has been successfully synthesized by a solvent-free reaction under temperatures as low as 80 °C within a very short time [29], this fast and mild method was used here to prepare the magnetic Fe3O4@OMS-2 nanocatalysts. The product as well as bare OMS-2 and Fe3O4 were then characterized in terms of the particle size, surface morphology, chemical composition, oxidation state and magnetic properties. Fig.1 gives the XRD patterns of the synthesized materials. For the bare OMS-2 shown in Fig.1(1), all peaks could be indexed to pure cryptomelane phase (JCPDS No. 29-1020) [29]. Fig.1(2) shows the pattern of the Fe3O4, which could be assigned to a spinel phase (JCPDS No.19–0629) [21]. Fig.1(3) shows the XRD pattern of the Fe3O4@OMS-2, which indicates that the products are a composite that contains cryptomelane-type OMS-2 (marked *) and spinel-type Fe3O4 (marked •). No other crystalline materials were detected in the products. The peak broadness in Fig.1(1) and (3) is indicative of the small crystal size of OMS-2. By using the Scherrer equation for the (211) peak, the size for pure OMS-2 and OMS-2 on Fe3O4 was calculated to be 12.4 nm and 11.3 nm, respectively. The results demonstrated that the addition of Fe3O4 did not result in a phase change in the structure of the OMS-2 nanoparticles. According to AAS analysis, the actual OMS-2 content in the Fe3O4@OMS-2 composites can be calculated to be ∼71.5 wt %. This is very similar to the theoretical value 73.4%, indicating that all of the Mn species from KMnO4 and Mn(Ac)2 were incorporated into OMS-2. OMS-2 Fe O (3) 3 4 10 20 30 40 50 2 theta (degree) 5 (440) (521) (2) 60 (002) (541) (422) (511) (600) (411) (400) (301) (211) (310) (200) (110) (220) Intensity (311) 70 (1) 80 Fig. 1 XRD patterns of OMS-2 (1), Fe3O4 (2) and Fe3O4@OMS-2 (3) Fig.2 shows the FT-IR spectra of pure OMS-2, pure Fe3O4, and the Fe3O4@OMS-2 nanocomposites. In the spectrum of OMS-2, the bands at around 3430 and 1630 cm-1 are due to the stretching and bending vibration of hydroxyl groups. The peaks at about 717, 531 and 478 cm-1 could be attributed to the vibrations of the MnO6 octahedral framework, which are the characteristic peaks of cryptomelane [30]. In the spectrum of Fe3O4, only the broad Fe-O band in the region from 520 to 800 cm−1 is clearly visible [19]. The spectrum of Fe3O4@OMS-2 is very similar to that of OMS-2. Clearly, the strong band at 583 cm-1 for Fe-O is greatly weakened compared to the pure Fe3O4 sample, indicating that the as prepared material may have a core@shell structure and the absorption of the Fe-O mode of the Fe3O4 phase may be therefore less pronounced because of the lower fraction of Fe3O4 in the surface. (1) Transmittance (%) 717 478 (2) 531 (3) 4000 583 3500 3000 2500 2000 1500 1000 500 -1 Wavenumber (cm ) Fig. 2 FT-IR spectra of OMS-2 (1), Fe3O4 (2) and Fe3O4@OMS-2 (3) TEM studies in Fig.3 reveal the details of the morphologies for the prepared nanoparticles. Similar to results reported in literature, the pure OMS-2 catalysts consist of a fine, uniform nanorod [29]. The range of diameters of these nanorods is about 8-12 nm, and the range of lengths is about 20-100 nm. The pure Fe3O4 shows a smooth surface and a mean diameter of about 100 nm with a narrow size distribution. After coating with OMS-2, the Fe3O4@OMS-2 has a very rough surface due to tightly attached rods-like particles. The OMS-2 shells are about 7-20 nm in thickness, and almost no individually separated OMS-2 particles are observed. Compared with pure OMS-2, the OMS-2 on Fe3O4 is more irregular and shorter (lower than 30 nm), indicating that it is harder for 6 OMS-2 to become longer in the presence of Fe3O4. These observations strongly suggest that the obtained composite catalysts possess well-defined core@shell structures with OMS-2 nanorods being effectively deposited on the surface of the Fe3O4 core particles by the solvent-free method, which not only do which effectively protect Fe3O4 nanoclusters from oxidation during reaction, also improve the dispersibility of OMS-2. The images of Fe3O4@OMS-2 in Fig 3(3) also demonstrate that OMS-2 nanorods randomly grow up and accumulated everywhere on the surface of Fe3O4, probably due to the presence of strong electrostatic attraction between OMS-2 and Fe3O4, as well as the particle–particle interactions of the OMS-2 nanoparticles. Fig. 3 TEM images of OMS-2(1), Fe3O4 (2) and Fe3O4@OMS-2 (3) Magnetization curves are measured for the as-synthesized Fe3O4@OMS-2 at room temperature with the results shown in Fig.4. The magnetization saturation value is about 22 emu g-1, which is much lower than that of the pure Fe3O4 (107 emu g-1). The sharp decrease in magnetic saturation can be explained by the decreasing of Fe3O4 content after deposition of OMS-2 (28.5%). Despite the reduction in magnetic strength, the materials are still strongly magnetic and can be concentrated by an external magnet, as shown in the inset. When the magnet was removed, the Fe3O4@OMS-2 were well dispersed again in the aqueous solution by shaking, demonstrating that the nanocomposites have good water dispersive ability. The excellent water-dispersive ability and 7 magnetic response allow for the tracking or separation of such particles in a magnetic gradient, paving the way for their sensitive detection and recycled catalytic degradation of organic pollutants. Fig. 4 M–H hysteresis loops of Fe3O4@OMS-2. Inset is the photographs of a vial containing Fe3O4@OMS-2 and AO7 before (i) and (ii) after addition of PMS and magnetic separation. N2 adsorption−desorption measurements were performed to investigate the Brunauer−Emmett−Teller (BET) specific surface area and the pore size of pure OMS-2, pure Fe3O4, and as-prepared Fe3O4@OMS-2. As shown in Table 1, the specific surface area, the total pore volume and the average pore size of OMS-2 were evaluated to be 129 m2/ g, 0.347 cm3/g and 10.5 nm, respectively. The mesopore volume was 0.326 cm3/g, constituting about 94 % of the total pore volume. The BET surface area (110 m2/g) and pore volume (0.259 cm3/g) of Fe3O4@OMS-2 was smaller that of pure OMS-2. However, the real values for OMS-2 on Fe3O4 will increase by taking the very minor contribution of Fe3O4 into account, as the BET surface area of pure Fe3O4 is only 5.26 m2/ g, and most of the oxide surface was occupied by OMS-2. Indeed, the BET surface area and total pore volume was calculated to be 154 m2/ g and 0.362 cm3/g by dividing the value of Fe3O4@OMS-2 by the content of OMS-2, respectively. They are larger than the values of pure OMS-2, in good agreement with the smaller size of OMS-2 on Fe3O4 surface. Table 1 BET surface areas of as-synthesized materials 8 A typical type II adsorption isotherm (hysteresis loop) for OMS-2 and Fe3O4@OMS-2 is shown in Fig.5(a); and Fig.5(b) gives a mesopore size distribution calculated by the Barrett-Joyner-Halenda (BJH) method, which exhibits a narrow pore size distribution in the range of 2-35 nm for the both materials. The pure OMS shows 2.4 nm and 17 nm of pore size at a maximum distribution, while the pore size for Fe3O4@OMS-2 is 2.4 nm and 11 nm. The average pore diameter of Fe3O4@OMS2 is slightly smaller than that of pure OMS-2. (b) 210 Desorption Dv (cm /g nm) 180 150 3 3 Volume adsorbed (cm /g) (a) 120 OMS-2 90 60 30 0 0.0 Fe3O4@OMS-2 0.2 0.4 0.6 0.8 1.0 0.016 0.014 Fe3O4@OMS-2 0.012 OMS-2 0.010 0.008 0.006 0.004 0.002 0.000 0 10 20 30 40 50 60 70 Pore diameter (nm) P / P0 Fig. 5 (a) N2 adsorption/desorption isotherm curve and (b) the pore size distribution of OMS-2 and Fe3O4@OMS-2 catalysts by BJH method. XPS was carried out to identify the surface elemental composition of the Fe3O4@OMS-2 nanocomposites. The survey spectra indicate that the Fe3O4@OMS-2 sample contains Mn, Fe, O and K with a mole ratio of Mn to Fe of 10:1. This result suggests that most of the iron oxides were coated by OMS-2, and is consistent with the above TEM analysis. Fig 6 shows the high-resolution XPS spectra of Mn 2p and Fe 2p. For comparison, the results of pure OMS-2 are also given. Gaussian-Lorentzian curve fitting was performed to describe the oxidation states. For Mn 2p 3/2 spectra of Fe3O4@OMS-2 shown in Fig.6(a), three peaks at 640.6, 641.3 and 642.8 eV with a ratio of 12.3:32.1:55.6 were obtained, which can be assigned to Mn(II), Mn (III) and Mn (IV) oxidation states, respectively [8], indicating that OMS-2 on Fe3O4 has a mixed-valent manganese framework with the coexistence of Mn(IV), Mn(III) and a minor amount of Mn(II). Fig.6 (b) shows the highresolution XPS spectra of Fe 2p. The respective binding energies of 710 eV and 724 eV indexed to Fe 2p3/2 and Fe 2p1/2, are consistent with the reported values of Fe3O4 9 [19]. For the pure OMS-2 nanorods, the Mn 2p XPS spectra in Fig 6 (c) are very similar to that of Fe3O4@OMS-2 with a ratio of 11.3:34.9:53.8 for Mn(II):Mn(III):Mn(IV) were obtained, suggesting that the grafting process did not destroy the oxidation states of Mn in OMS-2. No Fe was detected by the Fe 2p XPS spectra in Fig 6 (d). It is important to note that the presence of mixed valences of Mn can endow the Fe3O4@OMS-2 as a powerful candidate for the catalytic activation of PMS. Mn 2p 3/2 100000 (a) 120000 (c) 100000 Mn 2p 1/2 60000 40000 20000 5000 (b) 60000 40000 20000 635 640 645 650 655 0 630 660 Binding energy (eV) 3500 (d) Fe 2p 3/2 2500 Fe 2p 1/2 Intensity Intensity 3000 635 640 645 650 655 660 Binding energy (eV) 3000 4000 2000 1000 Fe 2p 2000 1500 1000 500 0 700 Mn 2p 1/2 80000 Intensity Intensity 80000 0 630 Mn 2p 3/2 710 720 730 740 Binding energy (eV) 0 700 710 720 730 740 Binding energy (eV) Fig. 6 Mn 2p and Fe 2p XPS spectra for Fe3O4@OMS-2 (a and b), and OMS-2 (c and d). 3.2 Catalytic activity The catalytic activity of the present Fe3O4@OMS-2 core-shell structures was evaluated with the decomposition of AO7 in aqueous solution in the presence of PMS. As shown in Fig.7(a), Fe3O4@OMS-2 showed high efficiency for AO7 degradation with a removal of 97 % after 15 min in the presence of 0.4 g/L PMS; while the addition of the same amount of PMS in the absence of the catalyst brought about only 14 % of AO7 removal. For the experiment with only Fe3O4@OMS2, the removal of AO7 was 51 %, probably due to the adsorption of AO7 on the surface of the catalyst. When pure Fe3O4 was stirred in the presence or absence of PMS for 15 min, there was also no apparent change in the concentration of AO7. In addition, the activity of the Fe3O4@OMS2/PMS system for degradations of other organic dyes such as KN-R, MB, RhB, X-3B and MO was 10 examined under similar conditions. All the pollutants could also be completely decomposed as shown in Fig.7(b). All the results clearly indicated that the Fe3O4@OMS-2/PMS was an efficient catalytic system for remediation of dyes wastewater. (a) (b) 1.0 0.8 0.8 0.6 0.6 Fe3O4@OMS-2/PMS Fe3O4@OMS-2 0.4 0.4 Fe3O4/PMS Fe3O4 0.2 0.0 0.2 PMS 0 3 6 9 RhB X-3B MB MO KN-R C/C0 C/C0 1.0 12 0.0 15 0 3 Time (min) 6 9 12 15 Time (min) Fig. 7 (a) AO7 degradation with different systems and (b) degradation of other organic dyes with Fe 3O4@OMS-2/PMS system. Manganese oxides at different oxidation states can activate PMS to produce SO4-• and SO5-• [31]. The reaction of SO4-• with H2O can further generate other species such as HO• [32]. Then the high reactivity SO4-• and HO• species can decompose organic pollutants efficiently. When addition of ethanol to the Fe3O4@OMS-2 system, which contains α-hydrogen and can react with HO• and SO4-● radicals at significant high rates [32], the catalyst efficiency decreased, suggesting the reaction following the radical mechanism. As the presence of a mixed-valent manganese species in Fe3O4@OMS-2 (Mn(IV), Mn(III) and Mn(II)), the mechanism of the catalyst for pollutants degradation can be proposed with involving the reduction of Mn(IV) and Mn(III) ions and also the oxidation of Mn(III) and Mn(II) ions by PMS. As shown in the following equations: HSO5MnIV + MnIII + SO5(1) + H+ MnIII + HSO5- MnIV + SO4- + OH- (2) MnIII + HSO5- MnII + SO5- + H+ (3) MnII + HSO5- MnIII + SO4- + OH- (4) SO4- + H2O HO + SO42- + H+ (5) SO4- + AO7 Products + SO42- + H+ (6) HO + AO7 Products + H2O + H+ (7) 3.3 Reusability 11 To study the stability of the as-prepared Fe3O4@OMS-2, the used catalyst was collected by magnetic separation, and redispersed in the fresh AO7 solution without any treatment. Then, 0.02 g PMS was added, and the second cycle of degradation was conducted. These steps were repeated several times. As shown in Fig.8 (a), there is little change of AO7 removal during the eight runs, which only decreased from 94% to 89%, indicating the high stability of the Fe3O4@OMS-2. The slight decrease in the oxidation capacity might be attributed to the adsorption of AO7 and its intermediate products on the surface of catalyst. In Fig.8 (b), the Mn concentration in the reaction solution was found to be less than 0.05 mg/l by using AAS spectroscopy, and no any Fe ions was detected. Previously, Anipsitakis and Dionysiou have found that Mn2+ could activate PMS to produce reactive radicals, but the rate of reaction was rather low [33]. Indeed, in our experiment with 5 mg/L Mn2+, only 14 % of AO7 was removed after 15 min, similar to the result with only PMS. These results confirmed that the leaching of metal ions into the liquid phase during the reactions was negligible, and the observed catalysis was intrinsically heterogeneous. (a) (b) Leached metal ions (mg/L) AO7 removal (%) 100 80 60 40 20 0 1 2 3 4 5 6 7 8 Run 0.10 0.08 0.06 0.04 Mn Fe 0.02 0.00 0 2 4 6 8 10 Time (min) Fig 8. (a) Degradation of AO7 using the recycled Fe3O4@OMS-2 catalyst and (b) leaching of Mn and Fe from Fe3O4@OMS-2 during the first run. 3.4 Effect of several parameters Further investigations were conducted to understand the effect of reaction conditions on AO7 degradation with the Fe3O4@OMS-2 catalyst. Fig.9 (a) shows the degradation efficiency at different AO7 concentrations. With increased AO7 concentration, the amount of dye in solution required more time to achieve a complete removal, which could be due to the same concentrations of produced reactive radicals under the same concentrations of the catalyst and PMS. For example, at a concentration of 10 mg/L, the complete AO7 removal was achieved in about 10 min, while at a 12 high concentrations of 200 mg/L, the time needed for nearly complete removal of the dye was 30 min. However, if we plot of the initial rate of AO7 degradation against its concentration, it can be seen that the degradation efficiency enhances lineally with the increasing of AO7 concentration, in consistent with most of the kinetic model. 1.0 1.0 10 mg/L 20 mg/L 50 mg/L 100 mg/L 200 mg/L 0.8 0.8 0.6 C/C0 C/C0 0.6 0.4 0.4 0.2 0.2 0.0 0.05 g/L 0.1 g/L 0.2 g/L 0.4 g/L (a) 0 5 10 15 20 25 0.0 30 (b) 0 5 1.0 0.024 g/L 0.05 g/L 0.1 g/L 0.2 g/L 0.4 g/L 15 20 25 30 3.75 5.18 7.04 9.25 0.8 0.6 C/C0 C/C0 1.0 10 Fe3O4@OMS-2 AO7 0.5 0.4 0.2 0.0 (c) 0 5 10 15 20 25 0.0 30 (d) 0 5 10 15 20 25 30 pH PMS Fig.9 Degradation of AO7 with Fe3O4@OMS-2/PMS system under different conditions: (a) Effect of AO7 concentration (Cat 0.4 g/L, PMS 0.4 g/L), (b) Effect of Fe3O4@OMS-2 concentration (PMS 0.4 g/L, AOII 20 mg/L), (c) Effect of PMS concentration (Cat 0.4 g/L, AO7 20 mg/L) and (d) Effect of initial solution pH (Cat, 0.4g/L, PMS 0.4 g/L, AO7 20 mg/L). Fig.9 (b) illustrates the change of AO7 concentration with time at different catalyst dosages. As expected, an enhancement of AO7 degradation was observed by increasing Fe3O4@OMS-2 concentration from 0.05 g/L to 0.4 g/L. The fact is evidently attributed to the increased concentration of active sites for reaction with PMS, which will generate more reactive radicals. In addition, the dye adsorbed on the catalyst increased with Fe3O4@OMS-2 dosage, which could also enhance the degradation rate. However, even at a low of 0.05 g/L, a 83 % removal of AO7 was reached within 30 min, suggesting the high efficiency of the catalyst. Under the conditions, the contribution of adsorption was minor. In what concerns the treatment process efficiency and operational costs, PMS has a high impact. To elucidate the role of PMS concentration on the degradation of AO7, some experiments were 13 carried out by varying the initial PMS concentrations. As shown in Fig.9(c), AO7 was slowly degraded in the presence of 0.024 g/L PMS. Under the conditions, the molar ratio of PMS/AO7 was 1.54. The incomplete removal of AO7 was probably due to lack of sufficient oxidant amount. When PMS concentration increased to 0.2 g/L, the degradation rate increased significantly, as more active radicals could be produced under a high concentration of PMS. However, further increase in PMS concentration to 0.4 g/L did not result in the same increasing trend of the degradation efficiency. The fact may be due to that the reaction proceeds via radical mechanism. The rate is limited by radical generation under low concentrations of PMS, but by radical attraction to the dye under a high PMS concentration. The influence of initial solution pH on AO7 degradation was also studied at five different pH values of 3.75, 5.18, 7.04 and 9.25, respectively. The results in Fig. 9(d) demonstrated that the degradation rate decreased as pH rose from 3.75 to 9.25. In acidic medium, the dye could be nearly completely degraded within 20 min. At an initial pH of 7.04, the degradation rate became much slower; however, a removal of 82 % could still be achieved within 30 min, implying that the catalyst still exhibited a good catalytic activity under neutral conditions. When the oxidation was carried out in alkaline medium (pH 9.25), a rapid degradation of AO7 during the first 2.5 min followed by a linear decreasing with a final removal of 57 % after 30 min was observed. In the whole pH range, AO7 and PMS are presented as negative ions [34]; while the rise of solution pH also increases the amount of negative surface charge on the catalyst [35]. This possibly inhibits the static interactions among OMS-2, AO7 and PMS, and consequently results in a slower rate of reactive species production and dye degradation. In addition, self-dissociation of PMS mainly through non-radical pathways increases with increase in solution pH, which would additionally reduce the degradation efficiency of target contaminant [36]. 4. Conclusions In summary, novel magnetic nanocatalysts involving deposition of OMS-2 particles on Fe3O4 cores have been synthesized for the first time by a solvent-free method. The composite catalysts obtained show well-defined core@shell structured spherical nanoparticles with a shell thickness of 14 about 7-20 nm and superior magnetic susceptibility. The as-prepared nanocatalysts exhibit remarkably higher catalytic activity in organic dyes degradation with PMS. Moreover, after separation with an external magnetic field, the catalyst retains a comparable activity. The present work not only provides a facile strategy for the fabrication of magnetically recyclable hierarchical core@shell structural nanocatalysts, but also opens a widely applicable route for alternative possible applications of magnetic hierarchical structured materials in related catalysis areas. References [1] M. Piumetti, D. Fino, N. Russo, Appl. Catal. B: Environ. 163 (2015) 277-287. [2] E. Rezaei, J. Soltan, N. Chen, Appl. Catal. B: Environ. 136-137 (2013) 239-247. [3] A. Zhang, W. Zheng, J. Song, S. Hu, Z. Liu, J. Xiang, Chem. Eng. J. 236 (2014) 29-38. [4] L. R. Pahalagedara, S. Dharmarathna, C. K. King’ondu, M. N. Pahalagedara, Y-T. Meng, C-H. Kuo, S. L. Suib, J. Phys. Chem. C (2014), DOI: 10.1021/jp505306q. [5] N. N. Opembe, C. K. King’ondu, A. E. Espinal, C-H. Chen, E. K. Nyutu, V. M. Crisostomo, S. L. Suib, J. Phys. Chem. C 114 (2010) 14417-14426. [6] J. Hou, L. Liu, Y. Li, M. Mao, H. Lv, X. Zhao, Environ. Sci. Technol. 47 (2013) 13730-13736. [7] H. Huang, Y. Meng, A. Labonte, A. Dobley, S. L. Suib, J. Phys. Chem. C 117 (2013) 25352-25359. [8] H. C. Genuino, Y. Meng, D. T. Horvath, C-H. Kuo, M. S. Seraji, A. M. Morey, R. L. Joesten, S. L. Suib, ChemCatChem 5 (2013) 2306-2317. [9] Y-Q. Deng, T. Zhang, C-T. Au, S-F. Yin, Appl. Catal. A: Gen. 467 (2013) 117-123. [10] G. D. Yadav, R. V. Sharma, Appl. Catal. B: Environ. 147 (2014) 293-301. [11] S. Luo, L. Duan, B. Sun, M. Wei, X. Li, A. Xu, Appl. Catal. B: Environ. 164 (2015) 92-99. [12] S. Dharmarathna, C. K. King’ondu, L. Pahalagedara, C-H. Kuo, Y. Zhang, S. L. Suib, Appl. Catal. B: Environ. 147 (2014) 124-131. [13] Y. Yang, J. Huang, S. Zhang, S. Wang, S. Deng, B. Wang, G. Yu, Appl. Catal. B: Environ. 150–151 (2014) 167178. [14] A. S. Poyraz, W. Song, D. Kriz, C-H. Kuo, M. S. Seraji, S. L. Suib, ACS Appl. Mater. Interfaces 6 (2014) 10986-10991. [15] J. Nie, H. Liu, J. Catal. 316 (2014) 57-66. [16] C. Almquist, M. Krekeler, L. Jiang, Chem. Eng. J. 252 (2014) 249-262. [17] H. C. Genuino, M. S. Seraji, Y. Meng, D.Valencia, S. L. Suib, Appl. Catal. B: Environ. 163 (2015) 361-369. [18] E-J. Kim, C-S. Lee, Y-Y. Chang, Y-S. Chang, ACS Appl. Mater. Interfaces 5 (2013) 9628-9634. [19] H. Zhang, G. Zhang, X. Bi, X. Chen, J. Mater. Chem. A 1 (2013) 5934-5942. [20] S. Kumar, S. T, B. Kumar, A. Baruah, V. Shanker, J. Phys. Chem. C 117 (2013) 26135-26143. [21] G. Xi, B. Yue, J. Cao, J. Ye, Chem. Eur. J. 17 (2011) 5145 -5154. [22] S. Xuan, W. Jiang, X. Gong, Y. Hu, Z. Chen, J. Phys. Chem. C 113 (2009) 553-558. [23] T. Zhang, X. Zhang, J. Ng, H. Yang, J. Liu, D. D. Sun, Chem. Commun. 47 (2011) 1890-1892. [24] T. Zhang, X. Yan, D. D. Sun, J. Hazard. Mater. 243 (2012) 302-310. [25] J. Zou, J. Ma, L. Chen, X. Li, Y. Guan, P. Xie, C. Pan, Environ. Sci. Technol. 47 (2013) 11685-11691. [26]. Y. Yao, C. Xu, J. Qin, F. Wei, M. Rao, S. Wang, Ind. Eng. Chem. Res. 52 (2013) 17341-17350. [27] M. M. Ahmed, M. Brienza, V. Goetz, S. Chiron, Chemosphere 117 (2014) 256-261. 15 [28] Z. Huang, H. Bao, Y. Yao, W. Lu, W. Chen, Appl. Catal. B: Environ. 154–155 (2014) 36-43. [29] Y. Ding, X. Shen, S. Sithambaram, S. Gomez, R. Kumar, V. M. B. Crisostomo, S. L. Suib, M. Aindow, Chem. Mater. 17 (2005) 5382-5389. [30] A. Iyer, H. Galindo, S. Sithambaram, C. King’ondu, C-H. Chen, S. L. Suib, Appl. Catal. A: Gen. 375 (2010) 295-302. [31] E. Saputra, S. Muhammad, H. Sun, H-M. Ang, M. O. Tadé, S. Wang, Appl. Catal. B: Environ. 142-143 (2013) 729-735. [32] Y. Ding, L. Zhu, N. Wang, H. Tang, Appl. Catal. B: Environ. 129 (2013) 153-162. [33] G. P. Anipsitakis, D. D. Dionysiou, Environ. Sci. Technol. 38 (2004) 3705-3712. [34] T. Zhang, H. Zhu, J-P. Croué, Environ. Sci. Technol. 47 (2013) 2784-2791. [35] M. J. Kosmulski, J. Colloid Interf. Sci. 275 (2004) 214-224. [36] A. Rastogi, S. R. Ai-Abed, D. D. Dionysiou, Appl. Catal. B: Environ. 85 (2009) 171-179. 16