CURRICULUM VITAE - Electronics and Computer Science

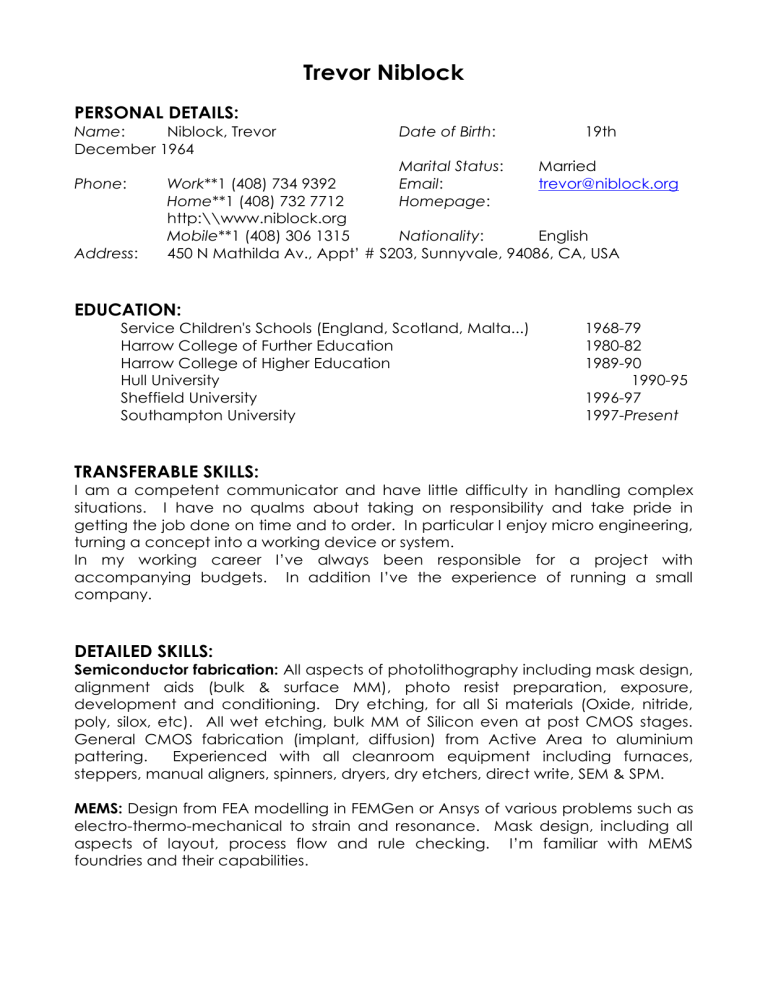

Trevor Niblock

PERSONAL DETAILS:

Name: Niblock, Trevor

December 1964

Phone: Work**1 (408) 734 9392

Home**1 (408) 732 7712 http:\\www.niblock.org

Date of Birth: 19th

Marital Status:

Email:

Homepage:

Married trevor@niblock.org

Mobile**1 (408) 306 1315 Nationality: English

Address: 450 N Mathilda Av., Appt’ # S203, Sunnyvale, 94086, CA, USA

EDUCATION:

Service Children's Schools (England, Scotland, Malta...)

Harrow College of Further Education

Harrow College of Higher Education

Hull University

Sheffield University

Southampton University

1968-79

1980-82

1989-90

1990-95

1996-97

1997-Present

TRANSFERABLE SKILLS:

I am a competent communicator and have little difficulty in handling complex situations. I have no qualms about taking on responsibility and take pride in getting the job done on time and to order. In particular I enjoy micro engineering, turning a concept into a working device or system.

In my working career I’ve always been responsible for a project with accompanying budgets. In addition I’ve the experience of running a small company.

DETAILED SKILLS:

Semiconductor fabrication: All aspects of photolithography including mask design, alignment aids (bulk & surface MM), photo resist preparation, exposure, development and conditioning. Dry etching, for all Si materials (Oxide, nitride, poly, silox, etc). All wet etching, bulk MM of Silicon even at post CMOS stages.

General CMOS fabrication (implant, diffusion) from Active Area to aluminium pattering. Experienced with all cleanroom equipment including furnaces, steppers, manual aligners, spinners, dryers, dry etchers, direct write, SEM & SPM.

MEMS: Design from FEA modelling in FEMGen or Ansys of various problems such as electro-thermo-mechanical to strain and resonance. Mask design, including all aspects of layout, process flow and rule checking. I’m familiar with MEMS foundries and their capabilities.

DQM (Design for Quality and Manufacture): familiar with most production processes and capabilities. Detailed knowledge of production engineer and design. Well versed in taking a MEMS device and packaging it to give the optimal interface with its environment whilst optimising cost and maintaining device performance (e.g. maximising quality).

QUALIFICATIONS:

Five O' levels: Math's, Physics, Accountancy, Economics and English

B.Eng. (Hons 2.1) Engineering Design and Manufacture (Mechanical Engineering)

M.Res (Master of Research/M.Sci) in Micro Electro Mechanical Systems (MEMS).

Ph.D. in MEMS ”Micro Scanning Probes” (see below)

Academic background

Ph.D.: Design & fabrication of a Micro Scanning Probe system. In essence a SPM on a chip. The main project components were conceptual design, modelling, process planning and fabrication followed by the testing of the device. The project involved the development of new processing techniques in photolithography, dry etching and bulk micro-machining. Testing involved the implementation of analogue electronics with a PCLabcard.

M.Res(M.Sci) Project: Design, fabrication and evaluation of a micromachined accelerometer.

M.Res taught subjects: Semiconductor Materials and Devices, Finite Elements for

Engineering Design, Analysis Techniques, Professional Skills, Commercial Awareness in R&D, Innovation and Project Management, Information Management.

B.Eng. Final Year Projects:

(DESIGN); Micro Linear Actuator & (RESEARCH); Finite Element Analysis of Low

Dimensional structure

B.Eng. Final year Subjects include: Semiconductor Technology, Finite Element

Analysis, Flexible Automation, Reliability, Control of Manufacturing Operations,

Design for Quality and Manufacture in Industry.

COMPUTER SOFTWARE:

L-Edit, AutoCAD, ANSYS, Pascal & C, MathCAD, MS Office and most engineering software.

I am at ease working in DOS, Win** or UNIX systems. I can find my way around most software packages, operating systems and networks. I have little difficulty learning new software.

OTHER QUALIFICATIONS, SKILLS & AWARDS

Barns Wallis Award for Engineering, Mechanical Engineering Workshop Proficiency

(Level 1 & 2), London Chamber of Commerce - Elementary book keeping, P1

Glider Pilots license (not current), RYA Sailing levels 1 & 2, RYA Power boating levels

1,2 & coastal endorsement, Carpentry, Full UK (since 1982) and Californian Driving

Licenses.

WORK EXPERIENCE:

Oct 01 to Present,

Inc.,

MEMS Program Manager, Analatom

The company produces MEMS devices, unique in that the finished packaged product is 100 m thick. My engineering duties include product modelling, design, testing and commercial production. One of my achievements has been producing ‘world first’ thin silicon devices and getting them into full-scale production. In addition, I write proposals, publish papers, and manage accounts -

I am responsible for a ($250kpa) budget to manage along with a team of two people. I also deal with present and potential customers and am solely responsible for bringing in $1.2m turnover into the company.

Design engineer, Geodetic technology LTD, Jan 96 to Aug,

UK

Develop prototype hexapod into a practical production model.

November 95, Design engineer, MBM Technology, UK

Contracted to aid in the design and production for a miniature reluctance motor for the Eurofighter.

July - October 94 Engineer, Philips, Eindhoven, Holland

Two projects: 1- Fault diagnoses on micro hexapod & 2- Development of a linear actuator.

February 85 - May 90 Proprietor Metro Fitting, UK

I set up and ran this company, which specialised in the fitting of clean rooms.

August 83 - February 85 Manager, Miranda Leisure LTD, UK

Responsible for the budget, hiring and management of 13 staff members.

ACTIVITIES, INTERESTS AND ACHIEVEMENTS:

My early childhood was spent in various countries throughout the commonwealth.

I spent the majority of my teens in Malta, where I was fortunate enough to enjoy a lively but responsible upbringing. In the early eighties I moved back to the UK and ran a show in a London hostess club, which in addition to being enjoyable gave me a good insight into 'different' lifestyles.

In 1985 I opened a specialist (clean room) fitting company with the aim of tapping into a lucrative gap in the market. This proved originally successfully, but the recession of the late eighties bit hard into profits, making the business no longer such an attractive proposition.

In 1989 I turned my attention to studying, as I was particularly interested in the new emerging micro/nano technologies. I entered into to the second year of an ONC course at the Polytechnic of Central London. The following year I began an engineering degree at the University of Hull. Whilst at the University I enjoyed studying and the academic environment. I showed particular ability to create and develop practical solutions to engineering problems, winning the Barnes

Wallis award for innovation and academic achievement.

My engineering interests lie in the development of a micro-machining/fabrication cell, which utilises devices and techniques other than (and addition to) those of current micromachining. This requires the use of a new low dimension design philosophy aimed at the selection of specific molecular and atomic structural properties.

REFEREES:

Professor Rob Yates, Gillette Advanced Technology Centre (UK), 460 Basingstoke

Road, Reading, Berkshire RG2 OQE, UK

Professor H. Kemhadjian, Head of Microelectronics group, ECS, Southampton

University, Soton, UK.

Professor K Swift, Department Of Engineering Design & Manufacture, University of

Hull, Cottingham Road, Hull, North Humberside. HU6 7RX

Mr. Pete van Renes, Group Leader, Mecatronics, Philips CFT, Stripe, Eindhoven,

Holland.