Влияние температуры расплава на структуру

advertisement

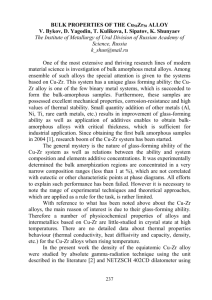

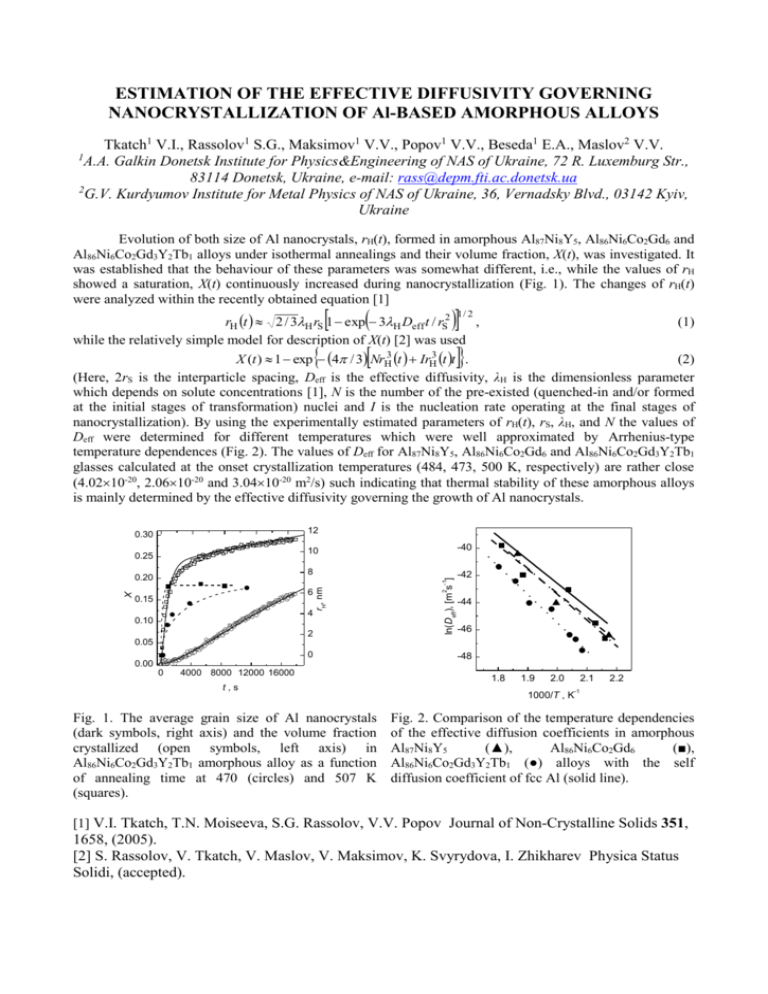

ESTIMATION OF THE EFFECTIVE DIFFUSIVITY GOVERNING NANOCRYSTALLIZATION OF Al-BASED AMORPHOUS ALLOYS Tkatch1 V.I., Rassolov1 S.G., Maksimov1 V.V., Popov1 V.V., Beseda1 E.A., Maslov2 V.V. A.A. Galkin Donetsk Institute for Physics&Engineering of NAS of Ukraine, 72 R. Luxemburg Str., 83114 Donetsk, Ukraine, e-mail: rass@depm.fti.ac.donetsk.ua 2 G.V. Kurdyumov Institute for Metal Physics of NAS of Ukraine, 36, Vernadsky Blvd., 03142 Kyiv, Ukraine 1 Evolution of both size of Al nanocrystals, rH(t), formed in amorphous Al87Ni8Y5, Al86Ni6Co2Gd6 and Al86Ni6Co2Gd3Y2Tb1 alloys under isothermal annealings and their volume fraction, X(t), was investigated. It was established that the behaviour of these parameters was somewhat different, i.e., while the values of rH showed a saturation, X(t) continuously increased during nanocrystallization (Fig. 1). The changes of rH(t) were analyzed within the recently obtained equation [1] rH t 2 / 3H rS 1 exp 3H Deff t / rS2 , while the relatively simple model for description of X(t) [2] was used 1/ 2 (1) X (t ) 1 exp 4 / 3 NrH3 t IrH3 t t . (2) (Here, 2rS is the interparticle spacing, Deff is the effective diffusivity, λH is the dimensionless parameter which depends on solute concentrations [1], N is the number of the pre-existed (quenched-in and/or formed at the initial stages of transformation) nuclei and I is the nucleation rate operating at the final stages of nanocrystallization). By using the experimentally estimated parameters of rH(t), rS, λH, and N the values of Deff were determined for different temperatures which were well approximated by Arrhenius-type temperature dependences (Fig. 2). The values of Deff for Al87Ni8Y5, Al86Ni6Co2Gd6 and Al86Ni6Co2Gd3Y2Tb1 glasses calculated at the onset crystallization temperatures (484, 473, 500 K, respectively) are rather close (4.0210-20, 2.0610-20 and 3.0410-20 m2/s) such indicating that thermal stability of these amorphous alloys is mainly determined by the effective diffusivity governing the growth of Al nanocrystals. 12 -40 8 -42 6 0.15 4 0.10 2 2 -1 X 0.20 10 ln(Deff), [m s ] 0.25 rH, nm 0.30 -44 -46 0.05 0 0.00 0 4000 8000 12000 16000 t,s Fig. 1. The average grain size of Al nanocrystals (dark symbols, right axis) and the volume fraction crystallized (open symbols, left axis) in Al86Ni6Co2Gd3Y2Tb1 amorphous alloy as a function of annealing time at 470 (circles) and 507 K (squares). -48 1.8 1.9 2.0 2.1 2.2 -1 1000/T , K Fig. 2. Comparison of the temperature dependencies of the effective diffusion coefficients in amorphous Al87Ni8Y5 (▲), Al86Ni6Co2Gd6 (■), Al86Ni6Co2Gd3Y2Tb1 (●) alloys with the self diffusion coefficient of fcc Al (solid line). [1] V.I. Tkatch, T.N. Moiseeva, S.G. Rassolov, V.V. Popov Journal of Non-Crystalline Solids 351, 1658, (2005). [2] S. Rassolov, V. Tkatch, V. Maslov, V. Maksimov, K. Svyrydova, I. Zhikharev Physica Status Solidi, (accepted).