Pipe Grid Specification

advertisement

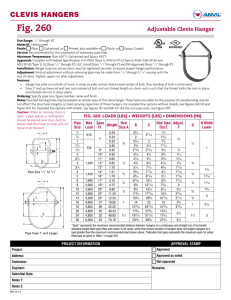

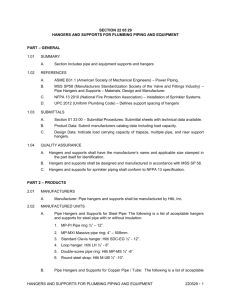

PIPE GRID SPECIFICATION SECTION 1.1 PIPE GRID A. Pipe Grid: Construct from 1-1/2 inch I.D. Schedule 40 black iron pipe. B. Live Load Capacity: 30 lbs/lineal foot. C. Fabricate pipe with a minimum number of splices with sections shorter than 21’-0” to be located in center of batten. D. Use an internal sleeve for splices with sleeve at least 18 inches long and secured with four (4) plug welds or four (4) 3/8-inch bolts with half-height "Nyloc" nuts. Threaded and coupled connections are not acceptable. E. Paint pipe grid with recognized high quality paint. F. Install pipe grid battens in a crossing pattern 90 degrees to each other in four (4) foot by four (4) foot bays. G. Join intersecting pipes with a 1/8-inch ASTM A36 HR steel formed intersection plate and two (2) 5/16-inch U-bolts, lock washers and hex nuts. H. Fabricate support hangers from 1/2-inch ASTM A193 Grade B7 threaded rod. Make connection of the hanger to the pipe grid by means of drop forged yoke end with a clevis pin and cotter pin to a two-piece pipe clamp. Form pipe clamp from 7-gage x 2- inch ASTM A36 HR steel joined with two (2) 3/8-inch Grade 5 hex bolts, lock washers and hex nuts. I. Rigidly mount support hangers to building’s support structure. Maximum spacing between hangers not to exceed 10’-0” in either direction and no more than 24-inches from a wall. J. Attach support hangers to lower pipes of grid. K. Support hangers shall have a 750 lb load capacity. L. End pipes two (2) inches off wall. Install internally sleeved wall flanges to prevent lateral movement of pipe grid. Attach wall flanges to building using construction appropriate fasteners for type of wall construction encountered. M. Size per Drawings and schedules. END OF SECTION 11060-1