Open_Channel_Design_project_final

advertisement

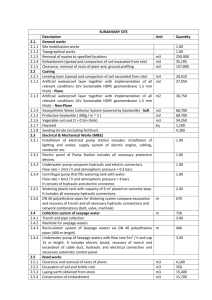

Submitted by: Thomas Dark Brian Billy Jed Parker, Naoki Mizukami CVEEN5450 Open Channel Flow Table of Contents 1. Introduction……………………………………………………………………………………. 3 2. Descriptions of rides……………………………………………………………………………..4 3. Destign method………………………………………………………….………………………5 3.1 Design criteria………………………………………………………………..….….…5 3.2.Hydraulic analysis and results…………………………………………………………5 3.2.1. Broad crested Weir analysis………………….………………………..….…….…...6 3.2.2. Pump analysis……………………………………………………………………….8 3.2.3 Head loss in the main looping channels……………………………………………....9 3.2.4 Water surface elevation for the slides…………………………………………….….10 4. Remaks…………………………………………………………………………………………14 Appendix A-1 Pump calculation (Excel Spreadsheet) A-2 Plan view (CADD Drawing) A-3 Profile view - two slides (CADD Drawing) A-4 Detail - Apex pool (CADD Drawing) Page 2 2/16/2016 1. Introduction One attraction that every water park must consider implementing is a lazy river. A lazy river can typically be defined as a lengthy continuous oval channel with a constant flow rate. Patrons can relish in the leisure of these attractions for many reasons. Typically on a lazy river people can lounge on their inflated tubes which go around the river at a snails pace. There are often multiple entrances and exits, eliminating any need for lines or regulations. For the patron who desires a simple and unrestrictive ride, the lazy river is ideal. Of course not everyone comes to a water park to lounge around on a tube. Some people enjoy fast paced rides in addition to the more tranquil lazy river settings. Lazy rivers also tend to use up large amounts of land and can require substantial amounts of water and maintenance. Certainly more efficient utilization of the lazy river concept could be achieved. This is why we propose the not-so-lazy river, a perfect synergy of tranquil tube riding combined with exciting fast paced slides. In this report, the descriptions of river rides and unique features are described in the next section. The details of hydraulic analysis are described that evaluate flow conditions in the channels and determine the size of hydraulic items (pumps) in the section 3. The issues related to maintenance, safety, operational cost are discussed in the section 4. Finally, CAD drawings are attached in the Appendices. Page 3 2/16/2016 2. Description of rides The conceptual design features a single looping channel extending upwards to a height of 10 ft to the park’s feature landmark, Mt. Olympus. Upon reaching the apex, two slide channels begins a sharp descent until it reaches the base of the ride where rougher waters are expected to be encountered. The ride culminates in enjoying a continuous, lazy, relaxing ride through looping channels. The conceptual design of the channel and its related structures are described here. Details of geometries of channels are shown in the CADD drawings in the appendix. The looping channel does not have slope; however, continuous flow will be created by supplying the pressure head with a pump. A diversion channel is split from the main looping channel where patrons are allowed to dismount the ride and provide for additional safety. The sliding channels (longer and gentler, and shorter and steeper) commence at the top of the mound (10 ft height) and feed into the main channel. A shallow pool (20 ft x 20 ft) and the ride station will be situated on the top of the mound adjacent to the main channel. Patron will be allowed access to the station utilizing stairs. Pumps will be utilized for pumping water from the looping channel to the upper pool in order to maintain the water height. The flow velocity and depth in the sliding channels will be controlled by adjusting the discharge rate from the pumps which will be controlled by the water levels in the pool. An additional pump will be utilized to control the discharges into the looping channel (24 in. water line). An orifice will be installed to discharge the water out of the channel in order to maintain the designed flow depth level of approximately 3 ft. The design also incorporates a pumping system that will inject water into the channel to provide additional energy to ensure design flow parameters are maintained. Page 4 2/16/2016 3. Design method The design proceeded in an iterative manner by comparing hydraulic analysis with the specified design constraints to determine the final geometry of the slide and channel profile. This section describes design criteria and hydraulic analysis methods and results. The hydraulic analysis described in this section is based on the final dimensions of the slide and main looping geometry. The hydraulic analysis and calculations were based upon the principles of open channel flow. 3.1 Design Constraints The design criteria as outlined by the client specify the following parameters based upon safety and park dimensions: The river rides are constructed within 20 acres of flat land. The starting point of ride and ending point are within 100 ft laterally. The starting point of ride and ending point are within 10 ft vertically. The ride velocity is maximum 10 ft/sec. Maximum channel depth is 5 feet. 3.2 Hydraulic analysis and results The following hydraulic calculations were conducted in details in order to ensure that the system is functional given the design criterion. Broad-crested weir analysis: The objective of this analysis is to determine discharge rate and pump head to convey water from the main channel to the apex pool so that the water storage is maintained in the apex pool. Pump analysis: the head requirements for the pump conveyance requirements were calculated utilizing the Hazen-Williams, Darcy-Weisbach, and Bernoulli’s equations for steel pipe. It was also indicated in the assumptions that a 24-inch water main would be situated adjacent to park and be capable of delivering an unlimited supply of water at 100 psi. Headloss estimate in main channel: The objective of this analysis is to determine the pump head to compensate for headloss in the main channel flow. HEC-RAS analysis: The objective of this analysis is to evaluate the hydraulic condition in the system as well as estimates of water surface elevation for each slide and main channel. Page 5 2/16/2016 3.2.1. Broad-crested weir analysis Broad-crested weir analysis was performed to determine discharge for each slide. Both the gentle slide and steep slide have the same invert elevation; consequently the discharge rate is equal. The discharge rate is assumed to be controlled by opening geometry for slide as shown in Figures 1A and 1B. The slides start with 7 feet long flat rectangular section immediately after opening. This rectangular section ties into the half circular shaped slide with 7 feet of radius that slide down to the main looping channel at the bottom. The pool depth at the apex is 4000 sq-ft in square shape with 5 ft deep wall. Water depth in the pool (y) is assumed to be constant. Water depth is set to be 4.4 ft from the bottom of the pool. In this analysis, water depths at the beginning of the slides are estimated. The water depth at the beginning of slide is assumed to be critical depth generated by the broad-crested weir. This water depth was used as boundary conditions for water surface profile analysis in HEC-RAS described later. yc y Q P The bottom of pool Figure 1A. Schematic side view of opening of slide. L yc y P The bottom of pool Figure 1B. Schematic cross section view of opening of slide. Page 6 2/16/2016 Because the discharge rate for each slide affect the water surface profiles downstream, this analysis necessitates iterative processes of adjusting slide invert height (P), water surface profile analysis, and adjustment of the slide geometry (slide profile). Equation for broad-Crested weir can be used to calculate the discharge [cfs] for each slide given the geometry. Discharge for broad-crested weir is given by Q Cv C d 2 2 g 3 3 12 LH2 3 1 where Cv is approach velocity coefficient, Cd is discharge coefficient, L is channel opening width [ft], H is head [ft]. Given the water depth (y) in the pool and height of slide channel opening (P), the head, H, can be obtain by H = y – P. Cd is 0.848 for broad-crested weir. Cv is given by H Cv e H 23 2 He is energy head at the weir (in this case, slide opening), and given by 2 Q L 2 He 3 g 13 3 In this case, there is no approaching velocity. a) Discharge and water depth for slides With initial guess of Cv and iteration, the discharges rate was calculated as follow. L-width [ft] 7 P-Height of weir [ft] 4 y-Water Depth [ft] 4.4 Cv-velocity coeff 1.164 Cd-discharge coeff. 0.848 Q-Discharge [cfs] 5.399 Compute Page 7 2/16/2016 b) Critical depth calculation The invert for slide 1 was determined to be located 4 ft above from the bottom of the pool. Opening of invert is 7 ft wide. The critical depth (yc) was computed with the critical depth equation, q2 yc g 13 5.40 7 2 32.2 13 0.26ft 4 This depth is assumed to be initial depth for each slide 3.2.3. Pump Calculations A pump will be utilized to convey water a height of 12 feet to the apex pool (Qgentle+Qsteep = 11.8 cfs). A 10-inch steel pipe was selected for the suction line and an 8-inch steel pipe was selected for the discharge line. Pumping water at a flow rate of 11.8 cfs is assumed to guarantees steady state condition within the pool. This design discharge was then incorporated into the following pump calculations. The schematic in figure 2 shows the parameters used in the pump analysis. The initial portion of the analysis was performed by designating the length of both the suction (Ls) and discharge lines (Ld). The frictional losses were accounted for by using the following Hazen-Williams relationship: 1.852 V 2 Q hLs K L L 0.285CD 2.63 2 g 5 The Energy equation was then used to evaluate the conditions at beginning of the suction line (point 1), which is the bottom main channel and the point of discharge (point 2), which is the apex pool. V2 P V 2 z1 1 h p 2 z 2 2 ht hL 2 g 2 g 1 2 P1 6 where P is the hydrostatic pressure, z is elevation, V is flow velocity, hp is pump head, ht is energy loss due to turbine, and hl is the frictional loss. Since the pressures at points 1 and 2 are considered atmospheric they can be eliminated from the equation. In addition, since there is no turbine the equation the equation becomes: h p z 2 z1 hL Q2 7 2449 2 gAD 2 The calculations for the head requirement were determined to be 150 feet. Suitable pumps for this application are subject to the discretion of the client. The remaining calculations and analysis is contained in appendix of this report. Page 8 2/16/2016 Patm Discharge line: Ld Apex pool V2 P Patm Z2 V1 Main channel Suction line: Ls Z1 Datum Figure 2. Schematic of pump system 3.2.4. Estimate of head loss in main looping channel This analysis is to determine the energy input from a pump based on head loss in main looping channel given a channel geometry and flow condition. Pump that discharge into the main looping channel is only driving force for continuous flow in the main channel because of flat channel. Energy supplied by flows from each slide is assumed to be minimal, and not included for the calculation. Energy head supplied by pump needs to be large enough that the flow can return to the pumping point. The following energy balance is considered: V V f Vave L y ave h p y ave 2g 2g 4 Rh 2g 2 2 2 8 where y is average flow depth in the main channel [ft], V is average velocity [ft2/s], L is flow length of the main channel (in this case, channel perimeter), f is friction factor, and Rh is hydraulic radius [ft]. LHS of the equation is the initial flow energy supplied by the pump and RHS is energy held by the flow after a lap. The last term of LHS indicates head supplied by pump. The last term of RHS indicates pressure drop due to friction; headloss. This energy balance equation assumes that flow depth and velocity does not change significantly. The equation is simplified as, f Vave L hp 4 Rh 2g 2 9 Friction factor f depends on Reynolds number ( Re Vave 4 Rh ) and relative roughness of channel materials. For fully rough turbulent flow, friction factor f is given by Page 9 2/16/2016 2 Rh f 2.03 log k 2 10 in which P B 1 2 1 0.9 B D 0.3 11 where P is wetted perimeter [ft], B is channel top width [ft], D is hydraulic depth [ft], and k is roughness height. The main channel is predetermined as concrete rectangular channel with 10 ft in width, 5 ft height. Flow in the main channel is maintained as 3 ft/sec and 3 ft in depth. Based on these parameters, the pump head required is computed as follow, Given parameters V ft/s 3 L ft 2261 y ft 3 B ft 10 A ft^2 30 P ft 16 D ft 3 Rh ft 1.88 σ 1.08 Constant μ lbm/ft/s 0.001038 ρ lbm/ft^3 62.42 g ft/s^2 32.2 k ft 0.0033 Roughness height (concrete) Computed parameters Re 1.35E+06 -> fully devloped flow k/Rh 0.00176 f 0.016 hp ft 0.72 Given this condition, minimum 0.72 ft of pump head needs to be supplied to overcome friction loss over one rap. 3.2.5. Water surface profiles for slides Once the slide geometry and profile were determined, water surface profiles were evaluated using HEC-RAS model. The purpose of this analysis is determine whether or not hydraulic jump occurs within the slides or not, and flow velocity at the exit of the slide is less than 10 ft/sec. This is consideration of safety issues. Page 10 2/16/2016 The following boundary conditions were used to simulate water surface profile for each slide (Table 1). The boundary condition upstream and flow was determined in the broad-crested weir analysis (subsection 3.2.1). Boundary condition downstream used normal depth given flow and slope in the lower section of the slides. Table 1. Boundary condition for water surface profile simulation in HEC-RAS. Flow Upstream Downstream Steep slide 5.40 cfs Critical depth = 0.26 ft Normal depth = 0.44 ft Gentle slide 5.40 cfs Critical depth = 0.26 ft Normal depth =0.86 ft The water surface profile computation requires manning’s equations to estimate energy grade slope for each cross section. This equation requires cross sectional geometry and manning’s roughness coefficient. The geometry of the slides is determined to be half circular shaped with 7 feet of radius. The material used in the slides is Polyvinyl chloride (PVC). The manning’s roughness coefficient is assumed to be 0.01.This cross section and roughness coefficient are defined in the HEC-RAS model. There is transition of the cross section of the slides from rectangular shape to circular shape at the top. This causes channel contraction (rectangular section is greater flow area than circular given the same width), resulting in energy loss. This was taken into account by defining head loss coefficient in HECRAS (KL = 0.1). First, subcritical flow condition was used to run models. However the results show water surface profile is match up with the critical depth. This means that the slide is classified as hydraulically steep channel since there is no solutions to subcritical depth for given the flow and slide geometries. Therefore supercritical flow condition was simulated next. Finally mixed flow simulation (both subcritical and supercritical flow may occur) was used to identify the possibility of hydraulic jump. It was found that the water surface profiles from supercritical flow and mixed flow analysis was identical for both gentle slide and steep slide case. Details features of water surface profiles for each slide are discussed separately as follows. a) Water surface profile for gentle slope As shown in the water surface profile along with critical depth, flow starts with critical flow and then becomes supercritical flow. This flow transition happens immediately past the flat entrance of slide. There is no indication of hydraulic jump even at the end of the slide. Rather, water depth remains constant, implying flow is nearly uniform flow. The fast flow indicated by average flow velocity happens in steep part around 600 ft from the downstream end (table 2), but it slows down toward the Page 11 2/16/2016 end of slide. The flow depth is typically shallow (~ 0.3 ft). This may cause contact between a raft bottom and slide itself. openchannel Plan: Plan 02 11/13/2006 s teep 1 16 Legend EG PF 1 Crit PF 1 14 WS PF 1 Ground Elevation (ft) 12 10 8 6 4 0 100 200 300 400 500 600 700 800 Slide Distance (ft) Figure 2. W.S profile for gentle slide. Table 2 Hydraulic variable at cross sections for gentle slide STA Dis. ft 8 707 7 700 6.5 650 6 600 5 500 4 384.94 3 300 2 200 1 100 0 0 Chnl Bott Elev W.S. Elev Crit Depth E.G. Elev E.G. SlopeAve. Vel Froude # ft ft ft ft ft/ft ft/s 14 14.33 14.26 14.42 0.002036 2.33 0.71 14 14.26 14.26 14.4 0.004238 2.92 1 13.05 13.48 13.63 13.96 0.013025 5.55 1.82 12.12 12.52 12.7 13.12 0.018192 6.24 2.12 10.27 10.67 10.85 11.27 0.018029 6.22 2.12 8.13 8.52 8.71 9.15 0.018966 6.33 2.17 7.22 7.67 7.8 8.09 0.010943 5.22 1.68 6.15 6.6 6.73 7.02 0.010657 5.18 1.65 5.07 5.52 5.65 5.94 0.010842 5.21 1.67 4 4.45 4.58 4.87 0.010992 5.23 1.68 b) Water surface profile for steep slope General flow conditions are similar to ones in gentle slope slide, as shown in the water surface profile and table. The flow starts with critical flow and then becomes supercritical flow past the flat entrance part. There is no indication of hydraulic jump even at the end of the slide. The fastest flow Page 12 2/16/2016 happens in the steepest part of the slide (approximately 413 ft from the downstream end), but it slows down toward the end of slide. The channel profile and flow condition are adjusted so that the greatest flow velocity dose not exceed the maximum allowable velocity (10 ft/s). Like the gentle slide, the flow depth is typically shallow (~ 0.4 ft), which may cause direct contact between raft and the bed of the slide. openchannel Plan: Plan 02 11/13/2006 gentle 1 16 Legend EG PF 1 Crit PF 1 14 WS PF 1 Ground Elevation (ft) 12 10 8 6 4 0 100 200 300 400 500 Slide Distance (ft) Figure 3. W.S profile for steep slide. Table 3 Hydraulic variables at cross sections for steep slide STA 5 4 3 2 1 0 Dis. Chnl Bott Elev W.S. Elev Crit Depth E.G. Elev E.G. SlopeAve. Vel Froude # ft ft ft ft ft ft/ft ft/s 433.1 14 14.31 14.26 14.41 0.001529 2.5 0.8 426.1 14 14.26 14.26 14.4 0.002508 2.92 1 413 11.82 12.09 12.4 14.01 0.057098 10 4.62 378 10.07 10.35 10.65 12.11 0.050281 9.98 4.35 323 8.42 8.73 9 10.01 0.031788 9.08 3.52 100 4 4.37 4.58 5.1 0.014061 6.85 2.41 Page 13 2/16/2016 4. Remark As a remark, safety issues, cost effectiveness and other appealing points are discussed. One of the most important features of the river slides is the two different slopes– “gentle” and “steep”. This allows patrons the option of riding slides with varying degrees of descent. Each slide is designed to ensure that the expected maximum slide velocity is no more than 10 ft/sec to account for safety issues. Assuming that the channel flow velocity is equivalent to the riding velocity there will be approximately 3 ft/sec difference between gentle and steep sloped rides. The apex pool is hexagonal shaped and situated at the top of the mound. Given this orientation it is possible to install an additional slide if necessary. For ease of installation composite plastic or fiberglass are viable options for tank material. The overall maintenance of the pool would be greatly simplified due to the lightweight, durable material. The construction of the river rides will not require any frame structures to gain the necessary elevation of the slide. Instead, earthwork will be required to build the 10 feet high mound. This is considered to be superior to the frame as far as safety’s concern for at least two reasons. First, there is no risk of collapse of the slide due to framing failure. It would also require routine inspections to prevent failure due to fatigue. In the past, a 17-year-old girl was killed and 32 teenagers were injured when a water slide collapsed at Waterworld USA park in Concord, California in 1997. In addition, the mound based slide also eliminates the possibility of falling accidents. This river ride system will recycle the water since water volume loss at the apex pool due to discharge to the slides is compensated from the main looping channel at the bottom via the pump. The water supply will be used for two purposes. One is to discharge to main loop channel to add the energy which is equal to head loss in the main looping channel using the main channel pump. However, the analysis shows this is minimal. The other purpose is to refresh the water in the entire system in a certain time interval. Page 14 2/16/2016 Appendix A1 - Pump Calculation summary Page 15 2/16/2016 Appendix A2 – Plan view Page 16 2/16/2016 Appendix A3 – Profile view of slides Page 17 2/16/2016 Appendix A4 – Detail for the apex pool Page 18 2/16/2016