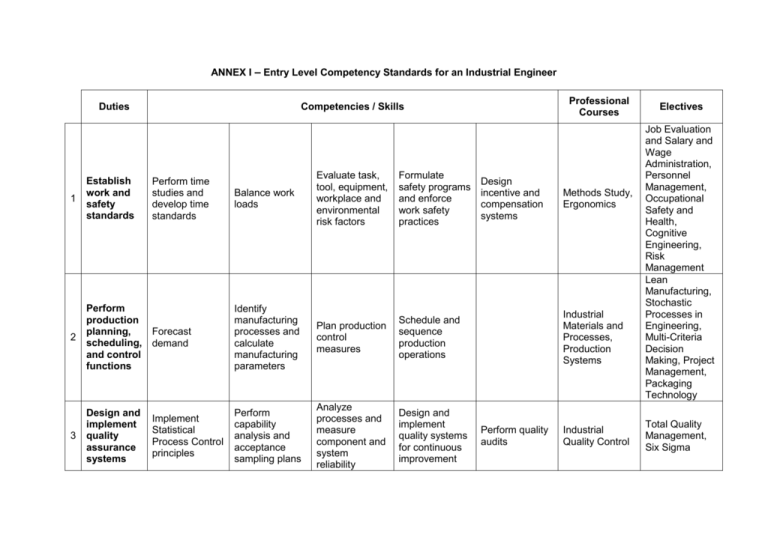

ANNEX I – Entry Level Competency Standards for an Industrial

advertisement

ANNEX I – Entry Level Competency Standards for an Industrial Engineer Duties Professional Courses Competencies / Skills Balance work loads Evaluate task, tool, equipment, workplace and environmental risk factors Formulate safety programs and enforce work safety practices 1 Establish work and safety standards 2 Perform production planning, Forecast scheduling, demand and control functions Identify manufacturing processes and calculate manufacturing parameters Plan production control measures Schedule and sequence production operations 3 Design and implement quality assurance systems Perform capability analysis and acceptance sampling plans Analyze processes and measure component and system reliability Design and implement quality systems for continuous improvement Perform time studies and develop time standards Implement Statistical Process Control principles Design incentive and compensation systems Methods Study, Ergonomics Industrial Materials and Processes, Production Systems Perform quality audits Industrial Quality Control Electives Job Evaluation and Salary and Wage Administration, Personnel Management, Occupational Safety and Health, Cognitive Engineering, Risk Management Lean Manufacturing, Stochastic Processes in Engineering, Multi-Criteria Decision Making, Project Management, Packaging Technology Total Quality Management, Six Sigma Duties Professional Courses Competencies / Skills 4 Prepare logistics plan Design inventory control systems Design warehousing operations Design distribution network and fleet management 5 Draw up facilities design and layout Calculate resource and space requirements Optimize flow of resources, materials, people, and information Select method for materials handling 6 Develop efficient information systems Conduct systems analysis to define information requirements Formulate systems and procedures, forms flow and design Identify appropriate data collection and processing systems 7 Conduct research and development Formulate the appropriate design of experiment Undertake an experiment Analyze and validate data Operations Research 1, Operations Research 2 Conduct capacity and process flow analysis Plan, design, and implement a computerbased information system Draw conclusions and recommendations from the results of the experiment Facilities Planning and Design Write and present technical reports Electives Enterprise Resource Planning, Supply Chain Management Strategic Planning, ComputerAided Manufacturing, Total Productive Maintenance and Reliability, Energy Management Systems Engineering, Information Systems Computer Applications in IE, Systems Simulation Advanced Statistics, Project Feasibility, Undergraduate Research Product Design and Development, Special Topics in IE, Special Problems in IE