aluminum to alum lab report

advertisement

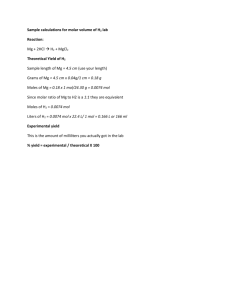

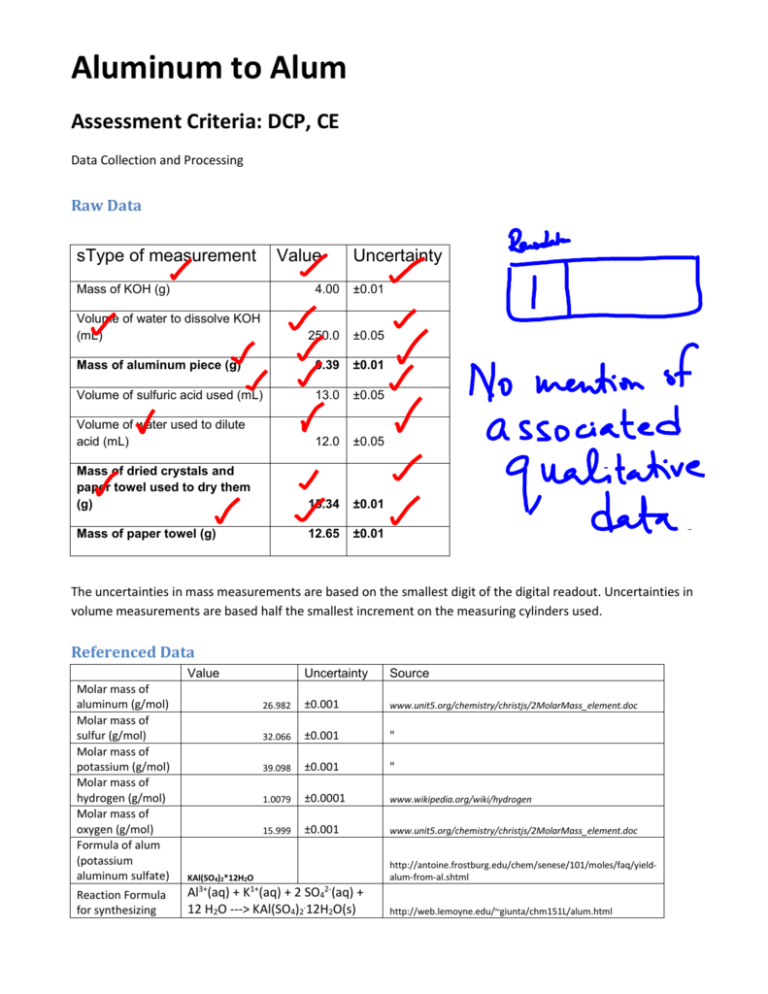

Aluminum to Alum Assessment Criteria: DCP, CE Data Collection and Processing Raw Data sType of measurement Value Mass of KOH (g) Uncertainty 4.00 ±0.01 250.0 ±0.05 Mass of aluminum piece (g) 0.39 ±0.01 Volume of sulfuric acid used (mL) 13.0 ±0.05 Volume of water used to dilute acid (mL) 12.0 ±0.05 Mass of dried crystals and paper towel used to dry them (g) 15.34 ±0.01 Mass of paper towel (g) 12.65 ±0.01 Volume of water to dissolve KOH (mL) The uncertainties in mass measurements are based on the smallest digit of the digital readout. Uncertainties in volume measurements are based half the smallest increment on the measuring cylinders used. Referenced Data Value Uncertainty Source 26.982 ±0.001 www.unit5.org/chemistry/christjs/2MolarMass_element.doc 32.066 ±0.001 " 39.098 ±0.001 " 1.0079 ±0.0001 www.wikipedia.org/wiki/hydrogen 15.999 ±0.001 www.unit5.org/chemistry/christjs/2MolarMass_element.doc Molar mass of aluminum (g/mol) Molar mass of sulfur (g/mol) Molar mass of potassium (g/mol) Molar mass of hydrogen (g/mol) Molar mass of oxygen (g/mol) Formula of alum (potassium aluminum sulfate) KAl(SO4)2*12H2O http://antoine.frostburg.edu/chem/senese/101/moles/faq/yieldalum-from-al.shtml Reaction Formula for synthesizing Al3+(aq) + K1+(aq) + 2 SO42-(aq) + 12 H2O ---> KAl(SO4)2.12H2O(s) http://web.lemoyne.edu/~giunta/chm151L/alum.html Alum from Aluminum Data Processing and Calculations Calculation of Yield Moles of Aluminum = Mass Al. Consumed /Molar mass = 0.39g/ 26.982 g/mol =0.014mol Mole ratio of Aluminum to Alum in Reaction = 1:1 Moles of Alum theoretically yielded= moles of Al used x mole ratio = 0.014mol x 1/1 =0.014mol Molar mass of Alum = MK + MAl + 2MS + 8MO +12 MH2O = 474.384 g/mol Theoretical mass of Alum yielded = moles of Alum theoretically yielded x molar mass of Alum = 0.014mol x 474.384 g/mol = 6.9g Actual Mass yield = Combined mass of crystals and paper towel – mass of paper towel = 15.34g – 12.65 g =2.69g % yield = (Actual yield/Theoretical yield) x 100% = (2.69g/6.9g)100% =39% Processed Data Table Quantity Moles of AL used (mol) Mole Ratio of Al:Alum Theoretical mole yield of Alum (mol) Molar mass of Alum (g/mol) Theoretical mass yield of Alum (mol) Actual Mass yield op Alum (g) Percent yield (%) Value 0.014 1 to 1 0.014 474.384 6.9 2.69 39 Uncertainty Calculations Unc. In mol of Al = ((0.01/ 0.39) + (0.001/26.982))*100% =2.56781% Unc. In Molar Mass of Alum = 0.001+ 0.001 + 0.001 + 0.0001 + 0.001 = ±0.0041g/mol % err. = (0.0041 / 474.384)*100% =0.0008% Uncertainty in Theoretical mass yield=2.56781% + .0005% = 2.5687% Uncertainty Actual mass yield= 0.01 + 0.01 =0.02g % err. =(0.02/2.69)*100% = 0.74349% Uncerainty in Final % Yield = 2.5687% + 0.74349% = 3.312% * 39.2 =±1.30% To proper significant figures = ±1% Final Value : 39 % Yield, ± 1% Conclusion and Evaluation Conclusion The final crystals formed were of a very wide range of sizes, with some barely visible, to others as large as approximately 1 cm3. Most of the crystals were quite clear, showing few signs of impurities. The percent yield of the experiment was 39% ± 1%. This was based on the mole ratio of Aluminum to alum in the reactions used, the moles of aluminum used in the reaction, calculated from the mass used, the theoretical value of moles and mass of alum supposedly to be produced. The actual mass of crystals measured was then compared to the theoretical value to acquire the final percent value. The yield is far below the perfect yield of 100%, but the difference can, and will, be explained in the evaluation. Evaluating Procedure The measurements taken were precise in this experiment. The final uncertainty was within 1% error, a strong point of this procedure. However, the procedure lacked the accuracy and high yield desired. Firstly, allowing the aluminum to dissolve in the Potassium hydroxide solution for only 15 minutes as per indicated in the procedure was not sufficient. Even though the aluminum piece used was torn into minute pieces in order to speed up the reaction, by the end of the 15 minutes, small pieces of aluminum remained. There were also several problems with the filtration process. The paper used needed to be folded in order to fit into the funnel to be used. This crease in turn was a weak point. Sometime during filtration, the paper tore, and some of the black precipitate from the aluminum, potassium and hydroxide solution was able to pass through. Moreover, the collection and decanting of the liquid from the crystal did not occur as effectively as possible. No matter how quickly the liquid was poured out of the beaker, some of the tinier crystal could not be retrieved, and when removing the crystals from the paper towel, not all could be removed for certain. Some residue could well have remained on the paper. Many crystals were lost in transport as well, when placing the crystal to dry, when carrying them over to the scale, etc. The container used to carry them around was unstable. Improving the Investigation First of all, instead of arbitrarily estimating the reaction time of the for Al to dissolve in the KOH solution, allowing all of the aluminum to dissolve, and ensuring that it does by step like stirring, should improve the yield. Instead of folding the filter paper into the cone to pour our liquid in to, taking the time to properly make a cone, using some adhesive tape to cover any crease, would reduce our risk of another contamination. Using a larger cone would increase the surface area of paper for the cone to be used during both filtration and decanting of the liquid from the crystals. This would be especially useful in the decanting step as all the liquid could be poured in at once, and none of the crystal would settle at the bottom of the beaker, unable to be poured out. Furthermore, placing the dried crystals and filter paper in a solid container could reduce the loss of crystal during handling when compared to just the paper.