Standard Operating Procedure: Ultra Hair Protein Additive - Bio-Link

advertisement

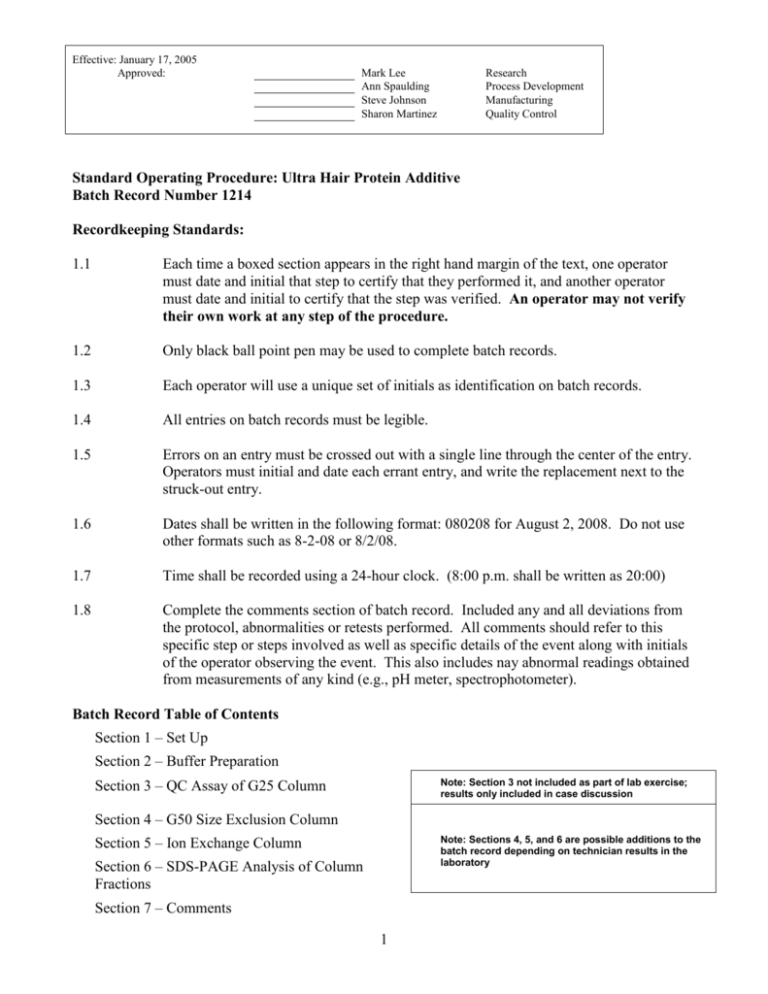

Effective: January 17, 2005 Approved: Mark Lee Ann Spaulding Steve Johnson Sharon Martinez Research Process Development Manufacturing Quality Control Standard Operating Procedure: Ultra Hair Protein Additive Batch Record Number 1214 Recordkeeping Standards: 1.1 Each time a boxed section appears in the right hand margin of the text, one operator must date and initial that step to certify that they performed it, and another operator must date and initial to certify that the step was verified. An operator may not verify their own work at any step of the procedure. 1.2 Only black ball point pen may be used to complete batch records. 1.3 Each operator will use a unique set of initials as identification on batch records. 1.4 All entries on batch records must be legible. 1.5 Errors on an entry must be crossed out with a single line through the center of the entry. Operators must initial and date each errant entry, and write the replacement next to the struck-out entry. 1.6 Dates shall be written in the following format: 080208 for August 2, 2008. Do not use other formats such as 8-2-08 or 8/2/08. 1.7 Time shall be recorded using a 24-hour clock. (8:00 p.m. shall be written as 20:00) 1.8 Complete the comments section of batch record. Included any and all deviations from the protocol, abnormalities or retests performed. All comments should refer to this specific step or steps involved as well as specific details of the event along with initials of the operator observing the event. This also includes nay abnormal readings obtained from measurements of any kind (e.g., pH meter, spectrophotometer). Batch Record Table of Contents Section 1 – Set Up Section 2 – Buffer Preparation Section 3 – QC Assay of G25 Column Note: Section 3 not included as part of lab exercise; results only included in case discussion Section 4 – G50 Size Exclusion Column Section 5 – Ion Exchange Column Note: Sections 4, 5, and 6 are possible additions to the batch record depending on technician results in the laboratory Section 6 – SDS-PAGE Analysis of Column Fractions Section 7 – Comments 1 Effective: January 17, 2005 Approved: Mark Lee Ann Spaulding Steve Johnson Sharon Martinez Research Process Development Manufacturing Quality Control BATCH RECORD NUMBER 1214 Preparation for Purification of UltraHair Protein Additive Section 1 – Set Up (page 1 of 2) Step Instructions Performed by Date Initial 1.00 Put on appropriate safety equipment (lab coat, safety glasses, gloves) 1.10 Note: if protocol is interrupted and student must leave immediate area, remove lab coat, gloves, and safety glasses and put on fresh gloves before restarting. Obtain all labware needed: 1.20 5 ml plastic disposable pipette with glass wool, tubing and pinch clamp (column) Pasteur pipettes and bulb 1.5 ml microfuge tubes Ring stand and clamp Small beaker for waste collection Rack to hold microfuge tubes Poly-prep chromatography column (Bio-Rad) Mini-Protean II electrophoresis equipment (Bio-Rad) (or similar electrophoresis equipment) Power supply Micropipettor and tips Microfuge tubes Gel drying kit (frame, cellophane sheets, and soaking solution) Boiling water bath or heat block Single edge razor blade Obtain all chemicals needed: 0.1M potassium phosphate buffer (pH 7.0) G50 resin (8 ml volume of settled resin/column), swollen overnight in 0.1M potassium phosphate buffer (pH 7.0) Batch 0298/12 UltraHair Protein Additive (protein mixture) 1.0M KCL, 0.1M potassium phosphate buffer, pH 7.0 SP-Sepharose (1.5 ml volume of settled resin/column) SDS sample buffer SDS-PAGE running buffer 4-20% preformed polyacrylamide gels, 10-well combs Molecular Weight standards (NOVEX See-Blue PreStained Standards) Coomassie Blue stain and destain 2 Verified by Date Initial Effective: January 17, 2005 Approved: Mark Lee Ann Spaulding Steve Johnson Sharon Martinez Research Process Development Manufacturing Quality Control Section 1 (page 2 of 2) Step Instructions Performed by Date Initial 1.30 Ensure lab bench or work surface is clear of all items not pertaining to protocol and has been decontaminated. Wash solution used: Time/Date cleaned: Surface is completely dry: 1.40 yes no Check that all scales, stir plates and micropipettes to be used are in working order. List all equipment to be used below. Include manufacturer, model number, and calibration date. (“Performed by” and “verification by” required for each item.) 3 Verified by Date Initial Effective: January 17, 2005 Approved: Mark Lee Ann Spaulding Steve Johnson Sharon Martinez Research Process Development Manufacturing Quality Control Section 2 – Buffer Preparation (page 1 of 2) Step Instructions Performed by Date Initial 2.00 Calibrate pH meter using commercially prepared pH buffers. Record data below. pH 4 buffer manufacturer: lot number: expiration date: 2.10 2.20 2.21 2.22 2.30 2.31 2.32 2.40 pH 10 buffer manufacturer: lot number: expiration date: If using pH strips, test standards and attach below. pH 4 strip pH 10 strip Weigh out 1.74 g potassium phosphate, dibasic scale tared: manufacturer: lot number: expiration date: amount used 1.74 g +/- 0.01 g Measure out 90 ml diH20 Dissolve dibasic potassium phosphate in diH20 potassium phosphate hydrated completely yes no date/time: Bring total volume to 100ml with diH20 Weigh out 1.36 g potassium phosphate, monobasic scale tared: manufacturer: lot number: expiration date: amount used 1.36 g +/- 0.01 g Measure out 90 ml diH20 Dissolve monobasic potassium phosphate in diH20 potassium phosphate hydrated completely yes no date/time: Bring total volume to 100ml with diH20 Mix 61 ml dibasic solution with 39 ml monobasic solution and check pH. Adjust to pH 7.0 with monobasic solution pH 7.0 yes no Label: 0.1M potassium phosphate buffer, pH 7.0 4 Verified by Date Initial Effective: January 17, 2005 Approved: Mark Lee Ann Spaulding Steve Johnson Sharon Martinez Research Process Development Manufacturing Quality Control Section 2 (page 2 of 2) Step Instructions 2.50 Weigh out 0.75 g potassium chloride (KCl) scale tared: manufacturer: lot number: expiration date: amount used 0.75 g +/- 0.01 g Measure out 9 ml potassium phosphate buffer, pH 7.0 Dissolve KCl in 0.1M potassium phosphate buffer, pH 7.0 KCl hydrated completely yes no date/time: Bring total volume to 10 ml with 0.1M potassium phosphate buffer, pH 7.0 Label: 1 M KCl, 0.1M potassium phosphate buffer, pH 7.0 2.51 2.52 Performed by Date Initial 5 Verified by Date Initial Effective: January 17, 2005 Approved: Mark Lee Ann Spaulding Steve Johnson Sharon Martinez Research Process Development Manufacturing Quality Control Section 4 – G-50 Size Exclusion Column (page 1 of 2) Step Instructions 4.10 Resin Hydration for 8 ml bed volume column Weigh out 1.0 g Sephadex G-50 resin scale tared: manufacturer: lot number: expiration date: amount used 1.0 g +/- 0.01 g Hydrate using 0.1M potassium phosphate buffer, pH 7.0 Place at 4ºC, overnight Column Preparation Pour an 8 ml bed volume G-50 column using a 5 ml disposable pipette as the column. Pipette prepared with glass wool stopper in the end of the pipette and 5 in of tygon tubing for flow control. Set up ring stand and clamp. Place column in vertical position. Clamp off the column and add 3-4 ml 0.1M potassium phosphate buffer. Swirl G-50 until the resin is well mixed. Add slurry to the column using a pasteur pipette and at the same time open the column. Do not allow the column to run dry! Add small aliquots of buffer to keep the fluid surface above the resin bed. The pipette will be filled to the lower blue line with settled resin for a total volume of 8 ml. Wash the column with 8 ml (one column volume) of 0.1M potassium phosphate buffer. Allow the fluid level to just reach the top of the resin bed and clamp the column off. Protein Separation Layer 100 μl protein mixture on resin bed Do not disturb the resin bed! Unclamp the column and allow the protein mixture to enter the resin. Clamp off the column. Wash protein mixture into resin using 100 μl of 0.1M potassium phosphate buffer (the sample volume) allowing it to enter the bed. Repeat (total of 2x sample volume of washes). Carefully fill reservoir with 0.1M potassium phosphate buffer, pH 7.0 4.11 4.12 4.20 4.21 4.22 4.23 4.30 4.31 4.32 Performed by Date Initial 6 Verified by Date Initial Effective: January 17, 2005 Approved: Mark Lee Ann Spaulding Steve Johnson Sharon Martinez Research Process Development Manufacturing Quality Control Section 4 (page 2 of 2) Step Instructions Performed by Date Initial 4.33 Label eight 1.5 ml microfuge tubes (1-8) Mark 1 ml volume on the outside of each tube with a pen (Sharpie) Unclamp the column and collect 1 ml fractions (8 total), and hold at 4ºC Do not allow column to run dry while collecting fractions! Record color of fractions collected 1. 2. 3. 4. 5. 6. 7. 8. 7 Verified by Date Initial Effective: January 17, 2005 Approved: Mark Lee Ann Spaulding Steve Johnson Sharon Martinez Research Process Development Manufacturing Quality Control Section 5 – Ion Exchange Column (page 1 of 2) Step Instructions 5.00 Column Preparation Obtain preswollen SP-Sepharose manufacturer: lot number: Pour column in Poly-prep disposable column. Set up ring stand and clamp. Place column in vertical position. Clamp off the column and add 1 ml 0.1M potassium phosphate buffer. Swirl SP-Sepharose until the resin is well mixed. Add slurry to the column using a pasteur pipette and at the same time open the column. Do not allow the column to run dry! Add small aliquots of buffer to keep the fluid surface above the resin bed. The final bed volume should be 1.5 ml of packed resin. Wash the column with 3 ml (two column volumes) of 0.1M potassium phosphate buffer. Allow the fluid level to just reach the top of the resin bed and clamp the column off. Protein Separation Layer 100 μl protein mixture on resin bed Do not disturb the resin bed! Unclamp the column and allow the protein mixture to enter the resin. Clamp off the column. Wash protein mixture into resin using 100 μl of 0.1M potassium phosphate buffer (the sample volume) allowing it to enter the bed. Repeat (total of 2x sample volume of washes). Carefully layer 2 column volumes (3 ml) of 0.1M potassium phosphate buffer, pH 7.0 to reservoir on column Label three 1.5 ml microfuge tubes W-1, W-2, and W-3 (mark 1 ml on tubes) Label three 1.5 ml microfuge tubes E-1, E-2, and E-3 (mark 1 ml on tubes) Unclamp column and collect fractions. W-1, W-2 and W3 (1 ml each). Clamp column off. Carefully layer 2 column volumes of 1M KCl, 0.1M potassium phosphate buffer, pH 7.0 to reservoir on column Unclamp column and collect fractions, E-1, E-2, and E-3 (1 ml each). Clam column off. Hold both was (W) and elution (E) fractions at 4ºC. 5.01 5.02 5.03 5.10 5.11 5.12 5.13 5.14 5.15 5.16 5.17 Performed by Date Initial 8 Verified by Date Initial Effective: January 17, 2005 Approved: Mark Lee Ann Spaulding Steve Johnson Sharon Martinez Research Process Development Manufacturing Quality Control Section 5 (page 2 of 2) Step Instructions Performed by Date Initial 5.20 Record any coloration differences in the collected fractions. 1. W-1 2. W-2 3. W-3 4. E-1 5. E-2 6. E-3 9 Verified by Date Initial Effective: January 17, 2005 Approved: Mark Lee Ann Spaulding Steve Johnson Sharon Martinez Research Process Development Manufacturing Quality Control Section 6 – SDS-PAGE Analysis of Column Fractions (page 1 of 4) Step Instructions 6.00 Solution Preparation Note: If commercially prepared buffers are available, they may be used in place of the buffers listed below. Prepare 300 ml of Running Buffer (25 mM Tris, 192 mM glycine, 0.1% SDS, pH 8.3) Weight out 0.9 g Trizma-base manufacturer: lot number: expiration date: molecular weight: Weight out 4.3 g glycine manufacturer: lot number: expiration date: molecular weight: Weight out 1 g SDS manufacturer: lot number: expiration date: molecular weight: Measure 10 ml diH2O Date/time prepared Chemical fully dissolved YES NO LABEL: 10% SDS Measure 3 ml 10% SDS Measure 250 ml diH2O and add Trizma-base, glycine and 10% SDS Date/time prepared Chemical fully dissolved YES NO Bring total volume to 300 ml LABEL: SDS-PAGE Running Buffer Prepare 1 ml of Sample buffer (125 mM Tris-HCl, 4% SDS, 20% glycerol, 10% β-mercaptoethanol) Prepare a 0.5M Tris-HCl, pH 6.8 solution manufacturer: lot number: expiration date: molecular weight: calculation for 0.5M, 20 ml 6.01 date/time prepared Chemical fully dissolved YES Performed by Date Initial NO 10 Verified by Date Initial Effective: January 17, 2005 Approved: Mark Lee Ann Spaulding Steve Johnson Sharon Martinez Research Process Development Manufacturing Quality Control Section 6 (page 2 of 4) Step Instructions Performed by Date Initial Prepare 0.04% Bromphenal blue manufacturer: lot number: expiration date: molecular weight: calculation for 0.04%, 10 ml 6.02 6.03 date/time prepared Chemical fully dissolved YES NO Solution Preparation Measure 250 μl 0.5M Tris-HCl, pH 6.8 Measure 400 μl 1-% SDS Measure 200 μl glycerol manufacturer: lot number: expiration date: Measure 100 μl β-mercaptoethanol manufacturer: lot number: expiration date: Measure 50 μl 0.04% Bromphenol blue Bring total volume to 1 ml Coomassie blue stain solution Weigh 2.5 g Coomassie blue R-250 manufacturer: lot number: expiration date: Measure 400 ml methanol manufacturer: lot number: expiration date: Measure 100 ml glacial acetic acid manufacturer: lot number: expiration date: Bring total volume to 1 L Destain Solution Measure 400 ml methanol manufacturer: lot number: expiration date: Measure 100 ml glacial acetic acid manufacturer: lot number: expiration date: Bring total volume to 1 L 11 Verified by Date Initial Effective: January 17, 2005 Approved: Mark Lee Ann Spaulding Steve Johnson Sharon Martinez Research Process Development Manufacturing Quality Control Section 6 (page 3 of 4) Step Instructions 6.10 SDS-PAGE: Preparation of gel box and samples List all materials needed below: 6.20 6.21 Collect column fractions to be assayed on gel Remove gel from leak-proof pouch percentage gel: manufacturer: lot number: expiration date: Remove comb and adhesive strip from gel Assemble gel in Mini-Protean II cell and fill upper and lower chambers with Running Buffer (300 ml/box) Label microfuge tubes and add SDS-sample buffer, 20 μl per tube List column fractions assayed: G-50 fractions: combine 3 and 4, combine 5 and 6 SP-Sepharose fractions: combine W1-3 and E1-3 Add 20 μl amounts of column fraction samples to appropriate tubes. 1. MW markers (see 6.26) 2. Original protein sample (Load) 3. G-50 fx 3,4 4. G-50 fx 5,6 5. SP-Sepharose W fxs 6. SP-Sepharose E fxs Prepare tube with molecular weight markers manufacturer: lot number: expiration date: Poke a hole in the top of each tube and place in heat block or boiling water bath for 3 min. Loading samples and running gel Load samples onto gel using gel loading tops and micropipettes (refer to Table below) Connect gel box to power supply and run gel at 150 V until the bromphenol blue tracking dye reaches the bottom of the gel (45-50 min) Visualize proteins in gel Disassemble gel box and place gel in Coomassie blue staining solution, microwave 30-45 sec and stain for 6.22 6.23 6.24 6.25 6.26 6.27 6.30 6.31 6.40 Performed by Date Initial 12 Verified by Date Initial Effective: January 17, 2005 Approved: Mark Lee Ann Spaulding Steve Johnson Sharon Martinez additional 15 min 13 Research Process Development Manufacturing Quality Control Effective: January 17, 2005 Approved: Mark Lee Ann Spaulding Steve Johnson Sharon Martinez Research Process Development Manufacturing Quality Control Section 6 (page 4 of 4) Step Instructions 6.41 Transfer gel to Destain solution, microwave 30-45 sec and destain 30 min – 1hr Transfer gel to water to continue destaining until the background is clear Dry gel according to instructions included with drying frame and cellophane sheets and append to SOP. 6.42 6.43 Label MW L (load) G-50 fx 3,4 G-50 fx 5,6 SP-S W SP-S E G-50 fx 3,4 G-50 fx 5,6 SP-S W SP-S E Amount of sample 5 μl 2 μl 20 μl 20 μl 20 μl 20 μl 20 μl 20 μl 20 μl 20 μl Performed by Date Initial Amount of SDS-sample buffer 2 μl 20 μl 20 μl 20 μl 20 μl 20 μl 20 μl 20 μl 20 μl 14 Load onto gel 5 μl 4 μl 15 μl 15 μl 15 μl 15 μl 15 μl 15 μl 15 μl 15 μl Verified by Date Initial Effective: January 17, 2005 Approved: Mark Lee Ann Spaulding Steve Johnson Sharon Martinez Research Process Development Manufacturing Quality Control Section 7 – Comments regarding Standard Operating Procedure: Ultra Hair Protein Additive Batch Record 1214 7.1 Document below all abnormalities observed as you followed the SOPs for Ultra Hair Protein Additive 15