RevisedSupplementalMater_Osako_CuO-TiO2_2

advertisement

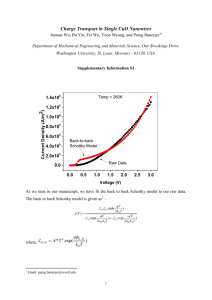

Supplemental Material Examination of interfacial charge transfer in photocatalysis using patterned CuO thin film deposited on TiO2 K. Osako,1,b) K. Matsuzaki,2,b) H. Hosono,2,3 G. Yin,1 D. Atarashi,1 E. Sakai,1 T. Susaki,2,a) and M. Miyauchi 1,4,a) 1 Department of Metallurgy and Ceramics Science, Graduate School of Science and Engineering, Tokyo Institute of Technology, 2-12-1 Ookayama, Meguro-ku, Tokyo, Japan 2 Secure Materials Center, Materials and Structures Laboratory, Tokyo Institute of Technology, 4259 Nagatsuta, Midori-ku, Yokohama, Japan 3 Materials and Structures Laboratory, Tokyo Institute of Technology, 4259 Nagatsuta, Midori-ku, Yokohama, Japan 4 PRESTO, Japan Science and Technology Agency (JST), 4-1-8, Honcho, Kawaguchi-shi, Saitama, Japan FIG. S1. X-ray reflection (XRR) pattern FIG. S2. XRD patterns FIG. S3. UV-Vis spectra FIG. S4. AFM images before Ag photodeposition FIG. S5. XPS spectra of Ag-3d core level on patterned CuO film FIG. S6. AFM image after photodeposition of Ag particles on pattered CuO film (100 nm thick) FIG. S7. AFM images after photodeposition of Ag particles on patterned CuO films log [Intensity (arb. units)] measured calculated 2 4 6 8 10 2 (deg) Rutile 220 CuO 111 Rutile 110 log [Intensity (arb. units)] FIG. S1. Typical fitting procedure of the X-ray reflection (XRR) pattern for CuO/TiO2. Using this approach, the film was determined to have a thickness of 5.6 nm. CuO 30 nm CuO 9 nm CuO 6 nm CuO 3 nm substrate 20 30 40 50 60 70 80 2 (deg) FIG. S2. XRS patterns for CuO/TiO2 thin films with various CuO thicknesses. The Cu-K line was used for measurement. Absorbance A 0.8 100) 0.28 A(CuO/TiO2) - A(TiO2) ( 1.0 6 CuO thickness 100 nm 30 nm 9 nm 6 nm 3 nm 0 nm (a) 0.6 0.4 (b) 4 2 0 400 500 600 700 800 900 Wave length (nm) FIG. S3. UV-Vis spectra for CuO/TiO2 thin films (a), and differential spectra versus rutile TiO2 substrate (b). The steep optical absorption around 420 nm (panel a) is attributed to the band to band transition in rutile TiO2 corresponding to its bandgap of 3.0 eV. The differential spectra (panel b) show absorption just below the energy level of rutile TiO2 absorption edge. Notably, because the wavelength of the blue light-emitting diode (LED) used in the present photo-reduction experiment ranged from 425 to 530 nm, this LED cannot excite electrons in the bare rutile TiO2 but can excite electrons both in CuO thick films and in thin CuO films on TiO2 substrate. (a) (b) D height 250nm A B C CuO: 100 nm TiO2 TiO2 5 m 5 m 0 2 m CuO: 6 nm 5 m 5 m 0 2 m (c) height 30 nm (d) A D B C Intensity (arb. units) FIG. S4. AFM images before Ag photodeposition for patterned CuO films with thicknesses of (a) 100 nm and (b) 6 nm. AFM line profiles of CuO films with thickness of (c) 100 nm and (d) 6 nm, respectively. (b) (a) 376 372 368 364 Binding Energy (eV) FIG. S5. XPS spectra of Ag-3d core level for 6 nm-thick patterned CuO film, (a) before and (b) after photodeposition. height 63 nm 63.39 [nm] 0.00 5 m5.00 5x 5.00 mµm 0 2 m 2.00 µm FIG. S6. AFM image after photodeposition of Ag particles on the patterned CuO film with 100-nm thickness. The probed region was very far from the film edges. (a) height 250.00 250 [nm] nm Ag CuO: 100 nm µm 55.00 m (b) TiO2 10.00 x 10.00 µm 10 m 10 m 00.00 Ag CuO: 6 nm TiO2 5.00 µm 10.00 x 10.00 µm 10 m 10 m 5 m height 100.00 100nm [nm] 00.00 FIG. S7. Low magnification AFM images after photodeposition of Ag particles on patterned CuO films with thicknesses of (a) 100 nm and (b) 6 nm. The edges of the CuO film were formed using photo-lithography (round shape) and a metal mask (square shape) for the 100-nm and 6-nm thick films, respectively.