Supplementary Information (doc 892K)

advertisement

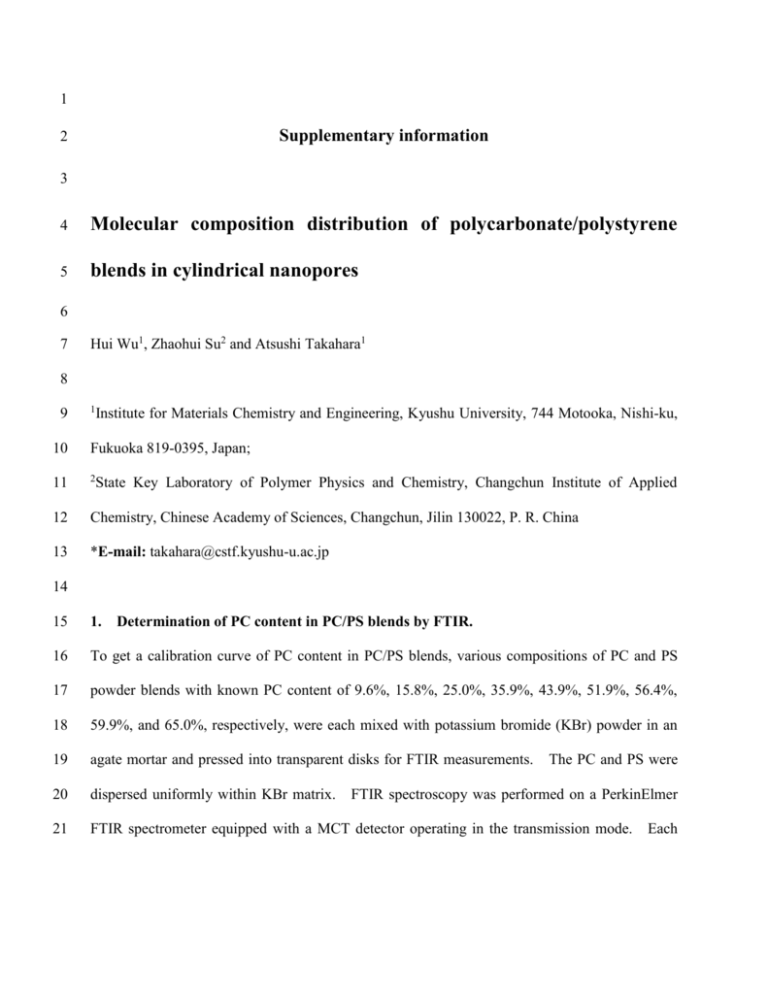

1 Supplementary information 2 3 4 Molecular composition distribution of polycarbonate/polystyrene 5 blends in cylindrical nanopores 6 7 Hui Wu1, Zhaohui Su2 and Atsushi Takahara1 8 9 1 Institute for Materials Chemistry and Engineering, Kyushu University, 744 Motooka, Nishi-ku, 10 Fukuoka 819-0395, Japan; 11 2 12 Chemistry, Chinese Academy of Sciences, Changchun, Jilin 130022, P. R. China 13 *E-mail: takahara@cstf.kyushu-u.ac.jp State Key Laboratory of Polymer Physics and Chemistry, Changchun Institute of Applied 14 15 1. Determination of PC content in PC/PS blends by FTIR. 16 To get a calibration curve of PC content in PC/PS blends, various compositions of PC and PS 17 powder blends with known PC content of 9.6%, 15.8%, 25.0%, 35.9%, 43.9%, 51.9%, 56.4%, 18 59.9%, and 65.0%, respectively, were each mixed with potassium bromide (KBr) powder in an 19 agate mortar and pressed into transparent disks for FTIR measurements. 20 dispersed uniformly within KBr matrix. 21 FTIR spectrometer equipped with a MCT detector operating in the transmission mode. The PC and PS were FTIR spectroscopy was performed on a PerkinElmer Each Page 2 1 spectrum was collected at 2 cm-1 resolution with 128 scans. 2 of PC/PS blends with various PC content. A 906 888 a Figure S1 show the FTIR spectra B 906 888 c Absorbance Absorbance b d e f g h i 2000 1800 1600 1400 1200 1000 -1 800 Wavenumber (cm ) 3 Figure S1. 930 915 900 885 870 -1 Wavenumber (cm ) 4 a b c d e f g h i Infrared spectra of PC/PS blends with different PC content: (a) 9.6%; (b) 15.8%; 5 (c) 25.0%; (d) 35.9%; (e) 43.9%; (f) 51.9%; (g) 56.4%; (h) 59.9%; and (i) 65.0%. 6 enlarged spectra in (A) ranging between 930 and 865 cm-1. (B) is the 7 8 9 In the range from 930 to 865 cm-1 in FTIR spectra of PC/PS film (Figure S2a), three peaks which located at 888, 906, and 918 cm-1 appear. The peak at 888 and 918 cm-1 is caused by the 10 C–CH3 stretching of PC1 (Figure S2b) and the peak at 906 cm-1 is the characteristic of 11 out-of-plane vibration of benzene ring of PS2 (Figure S2c). 12 the Levenberg-Maquardt least-squares algorithm routine of the OPUS software package ranging 13 from 930 to 865 cm-1 to obtain the individual peak intensities (peak area) of 888 and 906 cm-1. 14 The bandwidth of 888, 906, and 918 cm-1 band is about 14.0, 12.5, and 8.0, respectively. And a 2 Curve fitting was performed using Page 3 1 mixture shape of Lorentz and Gauss was employed to best match the original spectrum as 2 indicated in Figure S2. 888 906 918 Absorbance a b c 930 920 910 900 890 880 870 -1 Wavenumber (cm ) 3 4 Figure S2. FTIR spectra of: (a) PC/PS film; (b) PC film; and (c) PS film. The dashed lines 5 represent the result of curve-fitting ranging between 930 and 865 cm-1. 6 7 By measuring the intensity ratio between these two peaks at 888 and 906 cm-1 for the above 8 blends of known compositions, a calibration curve was obtained (Figure S3). According to 9 Beer’s law, the intensities of absorption bands are linearly proportional to the concentration of Thus, the intensity ratio of peak at 888 cm-1 (PC) 10 each component in a homogeneous mixture. 11 to peak at 906 cm-1 (PS) is related to the concentration (mass) ratio because of the identical path 12 length of source beam in the same mixed disks. Therefore, the ratio of the intensity of 888 to 13 906 cm-1 band and the PC content in PC/PS blend films can be written by 3 Page 4 APC aPCbPCcPC aPC mPC m k PC APS aPSbPScPS aPS mPS mPS 1 CPC 2 (1) mPC APC mPC mPS APC kAPS (2) where APC and APS are the intensity of PC and PS, as obtained by the absorbance areas ranging 4 from 930 to 865 cm-1; mPC and mPS are the mass of PC and PS in the blends, k is the ratio of 5 absorptive coefficients of aPC/aPS of PC at 888 cm-1 and PS at 906 cm-1, CPC is the content of PC 6 components in the PC/PS blends. Absorbance Ratio (A888/A906) 3 10 8 6 4 k = 4.47 ± 0.10 2 0 0.0 7 0.5 1.0 1.5 Mass Ratio (mPC/mPS) 2.0 Calibration curve of the ratio of the absorbances of peak at 888 cm-1 to peak at 906 8 Figure S3. 9 cm-1 in PC/PS blend films. 10 11 The k value was determined from the absorption measurements of mixtures containing known 12 amounts of compounds PC and PS at two specified frequencies, 888 and 906 cm-1. 13 calibration curves of PC/PS blends in Figure S3 which was fitted using linear regression, yields 4 The Page 5 Therefore, using the absorbance measurements of 888 and 906 cm-1 1 the k value of 4.47±0.10. 2 in the FTIR spectra, the following relationship is obtained to calculate the absolute PC content in 3 PC/PS blend nanorods/film A888 A888 4.47 A906 (3) 5 CPS 100% CPC (4) 6 where CPC, CPS represent the content of PC and PS in the PC/PS blends, A888 and A906 are the 7 respective band area for peaks at 888 and 906 cm-1, 4.47 is the ratio of absorptive coefficients of 8 the peak at 888 cm-1 to the peak at 906 cm-1. CPC 4 9 10 2. 11 The original PC/PS blend films with a thickness of 200 µm for the preparation of polymer blend 12 nanorods were obtained by compression molding the cast PC/PS film at 250 °C for 4 min and 13 quickly quenching the film in liquid nitrogen. 14 at 250 °C for 3 h and quenched into liquid nitrogen. 15 film for microscope observation were prepared by cutting the film using a razor blade. 16 Optical micrographs of PC/PS blend film before and after annealing. For the annealed film, the blend film was heated Thin slices of the cross section of PC/PS From the optical micrograph of the PC/PS film before and after annealing (Figure S4), many 17 dots and strips existed in the film. This indicates phase segregation was pronounced and PC/PS 18 blends were partially miscible system at 250 ºC. 19 strips were the PC-rich region, while the darker area was PS-rich region. 20 homogeneous blend because PC/PS was a partially miscible system. 21 5 FTIR analysis showed that the white dots or The film was not a Page 6 A B 1 2 Figure S4. Optical micrographs of a thin slice of a PC/PS film before (A) and after (B) 3 annealed at 250 °C for 3 h. 4 5 6 3. X-ray photoelectron spectroscopy (XPS) analysis of PC/PS film before and after annealing. 7 The XPS measurements were carried out on a PHI5800 (Physical Electronics Co., Ltd.) with an 8 Al Kα X-ray source. 9 chamber pressure was 10-9 Pa. 10 11 12 13 14 The X-ray gun was operated at 14 kV and 350 mW, and the analyzer Takeoff angles were kept constant at 45°. The PC content was quantified by XPS from the atomic ratio (rC/O) of C and O, based on the exclusive presence of oxygen in the PC: CPC 254 46 39rC/O (5) Before annealing, the PC content on the surface of the original PC/PS film was about 75.3%, showing the surface was enriched with PC component. 6 After annealed the PC/PS blend films at Page 7 1 250 °C for 3 h and quickly quenched in liquid nitrogen, the PC content on the surface of PC/PS 2 film decreased to 7.5 %, showing the PS component enriched on the surface. C Intensity O a b 600 500 400 300 200 Bidning Energe (eV) 3 4 Figure S5. XPS spectra of PC/PS film before (a) and after (b) annealed at 250 °C for 3 h. 5 6 REFERENCES 7 1 8 9 10 Lee, S. N., Stolarski, V., Letton, A. & Laane, J. Studies of Bisphenol-A-Polycarbonate Aging by Raman Difference Spectroscopy. J. Mol. Struct. 521, 19-23 (2000). 2 Liang, C. Y. & Krimm, S. Infrared Spectra of High Polymers. VI. Polystyrene. J. Polym. Sci. 27, 241-254 (1958). 7