Caracal document

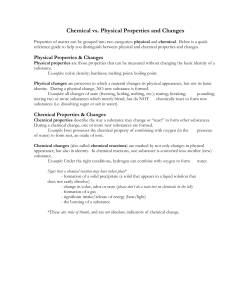

EUROPEAN COMMISSION

Directorate-General for Environment

Green Economy

Chemicals

Directorate-General for Internal Market, Industry, Entrepreneurship and SME's

Resources Based, Manufacturing and Consumer Goods Industries

REACH

Chemicals Industry

Brussels, 15 June 2015

Doc.

CA/55/2015

18th Meeting of Competent Authorities for REACH and CLP (CARACAL)

23-24 June 2015

Room 2D, Building Centre Albert Borschette, Brussels, Belgium

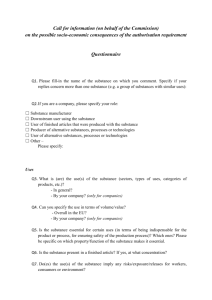

Concerns: Results of the public consultation on socio-economic elements related to ECHA’s sixth recommendation for prioritisation of substances for authorisation

Agenda Point: 7.2

Action Requested: For information and discussion

Written comments on this document should be sent by 15 July 2015 to GROW-

CARACAL@ec.europa.eu, valentina.bertato@ec.europa.eu

and pavel.prokes@ec.europa.eu

Results of the public consultation on socio-economic elements related to ECHA’s sixth recommendation for prioritisation of substances for authorisation

1. Introduction

From 1 September to 1 December 2014, ECHA conducted a public consultation on the draft

6 th

recommendation for prioritisation of substances for inclusion into Annex XIV, in order to obtain relevant information regarding the uses and conditions of use of twenty two substances included in the candidate list. In parallel with this consultation, in order to examine whether and how to take into account some socio-economic elements and the possible consequences of subjecting substances to the authorisation requirement prior to their inclusion in Annex

XIV, the Commission asked for submission of information on the possible economic, social, health and environmental impacts (costs and benefits) of the inclusion of the concerned substances in Annex XIV.

2. Overview

The Commission received 378 submissions in total from a range of industry associations, individual companies and other stakeholders. The largest part of submission concerned the group of borates (66% of submissions), followed by the group of lead-based substances

(23.4%) and by coal stream substances (8%).

Submissions were received from around twenty manufacturing sectors. The participating industries represent all the main downstream users in the supply chain of chemicals including basic metals, metalworking industries, aerospace, automotive, defence, rubber and plastics, electronics, glass, ceramics and the pharmaceutical industry. The industry associations provided often comprehensive information about the use of the substances as well as about the current economic situation of concerned sectors or sub-sectors, complemented with data about turnover, employment, trade exposure or the share of SMEs.

However, with regards to costs associated with possible authorisation requirements, only few submissions included a tentative quantification or an estimate. When included, such estimations were typically based on the 'no-use scenario'. Only few respondents commented on preparedness of the respondent to file, if relevant, an application for authorisation.

3. Value chain considerations

When evaluating the submissions, the Commission took a holistic approach looking at the uses and possible associated socio-economic impacts through the value chains of the concerned sectors.

The submissions documented a widespread use of the borates and lead compounds, in many sectors of manufacturing, implying a high number of indirectly affected (sub)sectors in the value chains. For example, in the case of lead monoxide, comments were made by ten different sectors or subsectors, in the case of boric acid by fourteen.

2

At the same time, several downstream sectors claimed important dependence on several substances that were subject of the public consultation that they would have to apply for authorisation and/or try to find substitutes for multiple substances at the same time in this respect the basic metals production along with metalworking and metal articles industries appear to be among the most concerned sectors. The metallurgical industry comprising steel, non-ferrous metals and ferroalloys documented use of five substances: disodium tetra-borate and boric acid, lead monoxide, pitch coal and tar high temperature, anthracene oil

(refractories, carbon electrodes). The situation of the ceramic and glass industry is similar due to dependence on supply of refractory products (based on coal stream substances) and in the case of special glass and frits due to direct use of lead–based substances.

4. Main use and recurring issues of concern

The analysis of submissions allowed for identification of recurring issues of concerns among the stakeholders. The following part summarises briefly the main points.

4.1 Borates

Main uses:

1

In the energy sector, the use of boric acid in Pressurized Water Reactors (PWR) of nuclear power plants is vital to control nuclear fission reaction and to ensure nuclear safety. The annual demand for boric acid for use in nuclear power plants in Europe is estimated to be less than 0.5% of the European borates market. In agriculture, the use of boron as a micronutrient in fertilisers (13.7% of total use) is essential for the growth and health of plants. In the manufacturing industry , the biggest share of borates is used in the manufacture of glass and frits (4.6%). Specific uses include application in coatings, industrial fluids or metallurgical applications, in manufacture of catalysts and fire retardants e.g. in insulation.

2 Borates are also used in low quantities in the production of pharmaceuticals and medical devices.

Main points and concerns:

No perspective of suitability and hence indispensability for the safe operation of the nuclear reactors and the implied economic impacts (nuclear energy accounts for

26.9 % of the total electricity production in Europe).

As boron is an essential nutrient in fertilisers, it cannot be substituted and there are risks of substantial monetary impacts in agriculture if these fertilisers are no longer available. According to an estimate, the economic impact of the borated fertilization absence in France alone would be more than € 800 million when taking into account impact on only three cultures (sunflower, rape and sugar beet).

Increase in production costs and risks that production will cease to be feasible vis-àvis increasing competition from countries outside the EU. This point was specifically raised by sectors that are exposed to an intense international competition, such as the basic metals.

1 The European Borate Association (EBA)

2 Report on critical raw materials for the EU CE 2014

3

Boric Acid is an essential component in the trivalent chromium (CrIII) electroplating process which has been developed by industry over several years as a substitute to the hexavalent chromium (CrVI) technology and as a substitute to chromium trioxide

(included in Annex XIV with a sunset date in September 2017). Applying authorisation on the use of boric acid would most likely stop further R&D activities on trivalent chromium alternatives.

Impossibility to replace borates with alternatives of the same level of performance and cost efficiency (e.g. with regards to the use of boric acid-based plating applications) or alternative substances do not exist (refractories or brazing fluxes).

Certain productions which depend on borate-based applications are highly regulated and have to comply with standardised design requirements. Any changes would require new testing and demonstrations (e.g. the aerospace with regards to plating applications).

Possible negative impacts on recycling or re-use of by-products. Borates are used as a slag stabilizer to transform slags (by-product of the stainless steel industry) into a usable aggregated material. With no viable alternative, slags could not be used or sold and thus would need to be disposed as waste without sustainable use.

4.2 Lead based substances

Main uses: Lead monoxide is used in a range of key EU industries including glass, frits, stabilisers, pigments, and rubber protection. Approximately 95% (510,000 t/a) of the total volume of lead monoxide is produced and used by the battery industry (automotive and industrial batteries). Largest quantities of lead tetroxide (orange lead) are used in production of batteries (81%), special and crystal glass (7%) and production of frits (11.5%). Smaller quantities are used in the explosives, pigments and rubber protection manufacture

3

.

Main points and concerns:

Increase in costs and feasibility to continue production in the EU vis-à-vis increasing competition coming from non-EU countries. In particular, special glass and frits producers expect sizeable effects of possible authorisation on production costs and consequently the ability of manufacturers in Europe to remain competitive.

No other substances can provide similar properties and/or all possible materials under testing are significantly more expensive. The industry of automotive and industrial batteries claims that, compared to the alternative products, lead-based batteries are the only technologically viable mass-market option for certain applications.

High up-front costs if there is need for replacing lead-based batteries by non-lead batteries in the European car fleet and diverse industry applications. The majority of these costs would be borne by consumers.

3 EUROBAT (producers of European automotive, industrial and special battery industries)

4

Possible negative impact on PVC recycling due to the content of lead-based stabilisers from the past.

4.3 Coal stream substances

Main uses: The coal based products - anthracene oil (AO) and coal, tar and pitch, high temperature (CTPHT) - are used as essential binders in the production of specific graphite electrodes. These electrodes have a wide range of applications in the production of steel, aluminium and ferro-alloys. Other important uses are in the manufacture of carbon, graphite and refractory products.

Main points and concerns:

Risk that production in coke plants in the EU ceases to be economically viable due to loss of downstream market for coal tar (COT) as an important by-product of metallurgical coke production. According to the submissions, the margins in the sector are low as a consequence of very tight economic conditions and constant price pressure from non-EU imports.

Reduced availability or quality of CTP-based refractory materials and CTP-containing electrodes may impact the reliability of supply for the main downstream users, specifically steel, aluminium, ferroalloys and non-ferrous metals.

As a consequence of the authorisation obligation, COT might be directed to energy recovery which would mean downgrading its position in the waste management hierarchy.

Non-existence of suitable alternatives. For example the submissions by the aluminium industry mention that there had been research by the major producing companies for the last 40 years to find alternative production routes or substitutes to CTP in anodes and cathodes but so far none have delivered a viable solution. For the refractory sector, submissions claim that no other materials can provide similar properties or all the other materials under testing are significantly more expensive.

CTPHT and AO are contained as a binder in tap-hole clay which implies indispensability for ensuring safe operation of blast furnaces in the steel industry.

Specifically in high pressure blast furnaces, the absence of CTPHT and AO may increase the risk of an uncontrolled opening of the tap hole.

4.4 4-Nonylphenol, branched and linear, ethoxylated

Main uses: According to received submissions, the substance is mainly used in the production of coatings, biocidal products/lubricants, degreasing agents, additives and or as a flotation chemical for the mining industry.

Main points and concerns:

5

Used in low concentration and, in the case of pharmaceuticals, under strict validation requirements by competent authorities. Any change in products or processes requires a revalidation of the process for biopharmaceutical manufacture.

4.5 1-Bromopropane or n propyl bromide

Main use: 1-Bromopropane or n-propyl bromide is used as degreasing solution in vapour degreasing process.

Main points and concerns:

High costs associated with change to more expensive and less efficient solvents.

Alternatively, high up-front costs and lower efficiency that would be associated with a change to water based system.

5. Concluding remark

Member States and stakeholders are invited to comment on any of the aspects presented in this document, either at CARACAL meeting or in writing by 15 July 2015.

6