Mn in Steel

advertisement

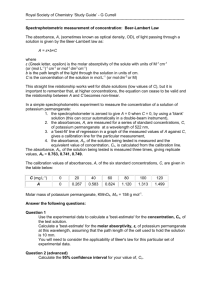

SCHC-266 Determination of Manganese in Steel Addendum 1. Dry the sodium oxalate standard, Na2C2O4 at 100oC for 1 hour. Let cool in your dessicator. 2. Dissolve the steel unknown in dilute HNO3 3. Standardize the prepared 0.10 N KMnO4 solution. unbalanced C2O42- + MnO4- CO2 + Mn2+ (HNO3 solution) 4. Calculate an approximate volume of KMnO4 required to reach the endpoint in each titration. Molecular weight of sodium oxalate is 134.00. In this experiment an indicator is not necessary, Why? 5. Beer’s Law Plot, Absorbance vs. concentration. Use two burets to prepare the various solutions. Your notebook should contain a Table with the solution number, mL of permanganate solution, mL of water, molarity, transmittance, and absorbance. The wavelength of measurement should be included in the table heading. Using Excel, prepare the Beer’s Law plot and calculate the molar absorptivity. Check your value with the instructor before proceeding. 6. The data for the plot of absorbance versus wavelength can be done with a partner. The Beers Law plot may be done with a lab partner but each student should analyze a steel sample. 1 Spectrometric-Determination of Mn in Steel Spectrometric methods are perhaps the most frequently used and important methods of quantitative analysis. They are based on the absorption of visible light or other radiant energy by a solution. The amount of radiant energy absorbed is proportional to the concentration of absorbing material in solution according to Beer’s Law. By measuring the absorption of light or other radiant energy, it is possible to determine quantitatively the amount of absorbing substance present. This experiment is a spectrophotometric determination of manganese in steel. The spectrometer used in this experiment is the Spectronic 20 or equivalent. Preparation of Standard Permanganate Solution Pipette quantitatively 10.0 mL of the Potassium Permanganate solution, “Baker Analyzed,” available in the laboratory into a clean 1000 ml volumetric flask. Dilute to the mark with distilled water. Mix well. Use this for the standard permanganate solution mentioned throughout this procedure. A. Absorption Spectrum of a Permanganate Solution A visible spectrum of MnO4- will be prepared by you. From the plot of absorbance vs. wavelength (nm) determine the max. B. Calibration Curve A plot of absorbance versus concentration (Beer’s Law plots) of various permanganate solutions will be made. Prepare the following solutions by mixing the indicated reagents in the following quantities using two burets or pipettes (measure volume to 0.02 ml): Soln # 1 2 3 4 5 6 7 8 9 MnO4- 20 20 20 20 20 10 10 10 5 H2O 5 10 15 20 30 20 30 40 45 Volumes are in mL. Record and use exact figures measured. Measure the absorbance of each of these solutions using the Spectronic 20 at the wavelength corresponding to the highest absorbance on your graph from the first part of this experiment (it should be about 525 nm). Re-measure the absorbance of the standard MnO4- solution at this maximum wavelength. Plot the absorbance of these solutions versus the permanganate concentration (Molarity) of each solution using Excel. Be sure to correct for any dilutions. Calculate , the molar absorptivity of MnO4-, using the Beer-Lambert Law, A = bc, where b (the cell length in centimeters) is equal to 1.00 cm for the Spectronic 20 cells. See your textbook for an explanation of the Beer-Lambert Law. 2 C. Determination of Mn in Steel The determination of manganese in steel is accomplished by dissolving the steel and oxidizing the resulting manganese (II) to manganese (VII), (MnO4-), which is then determined by spectrometry. The steel is first dissolved in dilute nitric acid that results in iron (II) and manganese (II). (Eq. 1) During the dissolution, NO2 and NO are also produced. These may interfere later in the experiment by reducing the periodic acid: hence, they are partially removed by boiling. Ammonium persulfate (ammonium peroxydisulfate) is used as an auxiliary oxidant, to oxidize the remaining oxides of nitrogen (Eq.2) and any organic material present. Unreacted peroxydisulfate is then decomposed by reduction with boiling water (Eq. 3). 3Mn(s) + 2NO3-(aq) + 8H+(aq) 3Mn2+(aq) + 2NO(g) + 4H2O(l) (1) 2NO2(g) + S2O82- (aq) + 2H2O(l) 2NO3-(aq) + 2SO42-(aq) +4H+(aq) (2) 2S2O82-(aq) + 2H2O(l) 4SO42-(aq) + O2(g) + 4H+(aq) (3) Theoretically, peroxydisulfate has the oxidizing potential to oxidize manganese (II) to manganese (VII), but the reaction is kinetically too slow to be useful. Potassium periodate oxidizes manganese (II) to manganese (VII) more rapidly and reproducibly and is preferred for the oxidation of (Eq. 4). The oxidation is carried out at the boiling point to insure a rapid reaction and to increase the solubility of the sparingly soluble potassium periodate. Since periodate also decomposes slightly at these temperatures, it is a good technique to add it in two portions, to maintain an excess. 2Mn2+(aq) + 5IO4-(aq) + 3H2O(l) 2MnO4-(aq) + 6H+(aq) + 5IO3-(aq) D. (4) Spectrometric Determination 1. Turn on the Spectronic 20 and allow it to warm up while the procedures below are carried out. 2. Weigh quantitatively three samples of the unknown steel from 0.50 to 0.75 g to the nearest 0.1 mg. Do not dry the steel. 3. Place the samples in separate 400 ml beakers, add 50 to 60 ml of dilute (1:3) nitric acid and heat in a hood to dissolve. Finally, cover and boil gently for two (2) minutes to remove nitric oxide. A black residue of carbon may remain in the solution at this point. 4. Remove the beakers from the heat and carefully sprinkle 1gram of ammonium persulfate into each beaker. Boil gently for 10 to 15 minutes to oxidize carbon. The excess ammonium persulfate will be destroyed by the heat. 3 5. Dilute each solution to about 100 ml, add 15 ml of 85% phosphoric acid and 0.5 g of potassium periodate. Boil gently for about three (3) minutes to effect oxidation to permanganate. Remove the heat and allow the sample to cool for about two minutes, then add an additional 0.2 g portion of potassium periodate. Boil for another minute or two. 6. Transfer each unknown solution to a 250 ml volumetric flask, and when cool dilute to volume. 7. Fill one cell with distilled water and a second with a solution of permanganate from one steel sample. Determine the absorbance at max. of the steel sample using the Spectronic 20. Repeat this with a second aliquot of the same steel sample. 8. Repeat step 7 using the second and third steel samples. 9. Determine the concentration of Mn in your solution using your Excel calibration. Report this concentration. Calculate the percent Mn in your original sample and report your result as the average of the three determinations. Report you confidence interval from your calibration. 4