01 - Sweets

advertisement

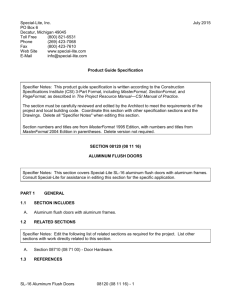

01 Southwest Aluminum Systems Chandler, Arizona Phone: 800-544-4044 SPECIFICATIONS FOR “MULTI-SLIDE” ENTRANCES PART 1 - GENERAL DESCRIPTION Work included: Furnish all necessary materials, labor and equipment for the complete installation of aluminum mall front as shown on the drawings and specified herein. (Specifier Note: It is suggested that related items such as glass, sealants and aluminum framing be included whenever possible.) Work Not Included: Structural support of the framing system, interior closures, trim, metal sub-sills. (Specifier list other exclusions.) Related Work Specified Elsewhere: (Specifier list.) QUALITY ASSURANCE Drawings and specifications are based upon the Plaza “Multi-Slide” Entrance system as manufactured by the Oldcastle Glass Engineered Products / Southwest Aluminum Systems. Whenever substitute products are to be considered, supporting technical literature, samples, drawings and performance data must be submitted ten (10) days prior to bid in order to make a valid comparison of the products involved. PERFORMANCE REQUIREMENTS (Specifier Note: The Plaza “Multi-Slide” Entrance system is not intended to be used as an exterior front. It can be used as an exterior front only when air infiltration, water penetration and deflection are not critical.) PART 2 - PRODUCTS MATERIALS Extrusions shall be 6063.T5 alloy and temper (ASTM B 221 alloy G.S. 10A-T5). Fasteners, where exposed, shall be aluminum, stainless steel or plated steel. Perimeter anchors shall be aluminum or steel, providing the steel is properly isolated from the aluminum. Glazing gaskets shall be vinyl extrusions. Track inserts shall be roll formed stainless steel. FINISH SPECIFICATIONS Note to specifier: Clear, Dark Bronze, and Black anodized finishes can be controlled to insure Uniform color. Light and Medium Bronze finishes can not be controlled as well and generally requires a longer lead time and are priced as Special Orders. A. All exposed surfaces of the framing system shall be finished with an Architectural Class Anodized Finish; chemical etch, medium matte, having a minimum thickness of 0.4 to 0.7 mil, integrally or electrolytically deposited colored anodic coating sealed in accordance with ASTM specifications B-136-77 and free of scratches and other blemishes. The coating shall conform to the following minimum requirements for thickness and weight and shall be continuous, fully sealed when measured in accordance with ASTM B137-45, ASTM B244-68, and ISO 3210.1 1. Anodized finish color shall be (Light, Medium, Dark Bronze, or Black) to match approved sample. B. All exposed surfaces of the framing system shall be finished with an Anodized Finish; caustic etch followed by an anodic oxide treatment to obtain a clear anodized finish, medium matte, having a minimum thickness of 0.4 mil, integrally or electrolytically deposited colored anodic coating sealed in accordance with ASTM specifications B-136-77, and free of scratches and other blemishes. 1. Anodized finish color shall be Clear Anodized to match approved sample. The following “paint” finishes are available from OLDCASTLE GLASS ENGINEERED PRODUCTS / SOUTHWEST ALUMINUM SYSTEMS please select one or more types of paint as required by your project. C. All exposed surfaces of the framing system shall be finished with a high performance pigmented organic coating finish. February 2006 02 Aluminum surfaces shall be cleaned with inhibited chemicals, conversion coated with acid-chromate-fluoride-phosphate treatment, and painted with organic coating specified below. Prepare, pre-treat and apply coating to exposed metal surfaces to comply with coating and resin manufacturer’s instructions providing a finish free of scratches and other blemishes. 1. Fluorpolymer Coating shall conform to American Architectural Manufacturers Association 2605.2, Specifications for High Performance Organic Coatings on Architectural Extrusions and Panels, ”containing a minimum of 70% Kynar 500 resin with a minimum of 1.2 mil dry film thickness. 2. Color shall be _________________________ to match approved sample. ***OR*** 1. Fluorpolymer Coating shall conform to American Architectural Manufacturers Association 2604.2, “Specifications for High Performance Organic Coatings on Architectural Extrusions and Panels,” containing a minimum of 50% Kynar 500 resin with a minimum of 1.2 mil dry film thickness. 2. Color shall be _________________________ to match approved sample. HARDWARE Hardware for the Plaza “Multi-Slide” Entrance system shall be the entrance manufacturers standard as follows: • Tandem ballbearing caster • Adams Rite MS 1850-H hook boltlock • Cylinders (interior and exterior) • Flush face pull FABRICATION Fixed and sliding panels shall have a nominal depth of 1 3/4" each to insure rigidity and prevent racking. The weight of each panel shall be supported by the base tracks. Sliding panels shall be equipped with two center pivoted spring loaded, tandem wheel assemblies, each capable of supporting a moving weight of 300 pounds and shall be equipped with two self-contained, steel balI bearing rollers. Sliding panels shall not be removable when in a locked position. PART 3 - EXECUTION INSTALLATlON All jambs, head and sill track shall be set in correct locations as shown in the details and shall be level, square, plumb and in alignment with other work in accordance with the manufacturer’s installation instructions and approved shop drawings. PROTECTION AND CLEANING After installation, the General Contractor shall adequately protect exposed portions of aluminum surfaces from damage by grinding and polishing compounds, plaster, lime, acid, cement, or other contaminants. The General Contractor shall be responsible for final cleaning. (NOTE: In keeping with Oldcastle Glass Engineered Products / Southwest Aluminum Systems continuous policy of product improvements, all specifications are subject to change without notice.) February 2006