manufacturing experience - VTC

advertisement

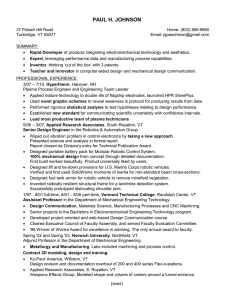

PAUL H. JOHNSON 292 Central Street Home office: (802) 485-4503 Northfield, VT 05663 Email: pjohnson@vtc.edu SUMMARY: " Rapid Developer of Products Integrating Electromechanical Technology and Aesthetics. Expert and Innovator in Computer-Aided Design and Mechanical Design Communication. PROFESSIONAL EXPERIENCE: 1/97 -8/01 full-time, 8/01 -Present part-time, Vermont Technical College, Randolph Center, VT Assistant Professor in the Department of Mechanical Engineering Technology. .Design Communication, Materials Science, Manufacturing Processes and CNC Machining. .Senior projects in the Bachelors in Electromechanical Engineering Technology program. .Developed project oriented and web-based Design Communication course. .Chaired Executive Council of Faculty Assembly, and served Faculty Evaluation Committee. .'98 Winner of Wonka Award for excellence in advising. The only annual award to faculty. .'97 Rapid Product Development presentation for 100+ executives. Spring '02 and Spring '03, Norwich University, Northfield, VT Adjunct Professor in the Department of Mechanical Engineering. .ME 358 Metallurgy and Manufacturing. Labs include machining and process control. Training faculty in the use of AutoCAD 2002. 3/98 -Present, Lefties Design, Montpelier, VT Partnered with Mary Waldo of VTC to provide geometric computer modeling, design and training. .4/00 -11/00, Ko-Pack America, Williston, VT Design revision and documentation overhaul of 200 and 400 series Flex-o-stations. .3/98 -6/98, Waterford Irish Stoves, W. Lebanon NH Created assembly and part drawings of a stove prototype for a critical safety review. .;7/96 -Present, Paul Johnson Engineering, Northfield, VT " / Contract geometric computer modeling, mechanical design and training. .8/99 -9/99, Applied Research Associates, S. Royalton, VT Weapons Effects Group. Modeled shape and volume of craters around a tunnel entrance. .8/96 and 9/96, Black & Decker, Shelton, CT OSD garment iron program. Trained a team of designers in data management, computer modeling and communication while responsible for final cosmetic surfaces and transfer to production tooling. 7/89 -7/96, Black & Decker's Household Products Division, Shelton, CT CAD/CAM Engineer, Sr. CAD/CAE Engineer and CAID Integration Engineer. Three unique titles track a seven-year evolution from taskmaster within a highly specialized technical infrastructure to product development expediter within an international network of designers, manufacturing engineers and toolmakers. Contributed innovative concepts for aesthetics, human factors, mechanics and manufacturing, while working within teams to develop new product ideas into production tooling. Constructed 3D computer models that yield appearance models for industrial design and market research, functional prototypes for engineering, and data for injection mold production on over 15 new product development programs including: PAUL H. JOHNSON (page 2) The SB400 ScumBuster, cordless tub and tile cleaner; Envisioned and used 'full contact' design process giving us our fastest and most innovative program. Patents 5,697,115 on 'auto eject' and 5,718,014 on overmolding for low cost submersibility. Polypropylene housing design strong enough to withstand 500 psi. overmold packing pressure. Winner of Popular Science Best of What's New, 12/96. .The SV3000 FloorBuster, lightweight upright cordless vacuum cleaner; Used dimension driven 3D solid models to explore compactness and manufacturing versatility. Designed functional prototypes that verified vacuum performance and handle stiffness. Winner of Appliance Manufacturer's Excellence in Design competition '96, May feature. .The AC8000 Collector, most powerful corded hand-held vacuum cleaner; Coordinated critical path tasks. Introduced composite functional prototyping for rapid evaluation of mechanical concepts. ( Patent 5,388,302 on 'drum-head' assembly architecture and air-flow chamber. .The T -245 Metropolitan, 1950's retro-cosmetic toaster; Developed radius blend surfacing technique for modeling a 'hand worked' aesthetic. Article, "Engineering the Aesthetic", Manufacturing Systems 3/93 pp.20. Winner of the Silver Idea92 Award for industrial design excellence. 1/88 -12/88, Lehigh University CIM Lab (Computer Integrated Manufacturing) Design Engineer, using 3D solids. .Designed electromechanical continuous feed film splicer for, INPACO Inc., Nazareth, PA. EDUCATION: BS Mechanical Engineering '89 BA Philosophy '89 Lehigh University, Bethlehem, PA. Five year dual-degree program. TECHNICAL SKILLS: .Expert in Mechanical Desktop solids, assembly modeling and documentation. .Proficient in Autodesk Inventor solids, assembly modeling and documentation. .Proficient with web authoring, distance learning and design communication tools (Blackboard, Netscape Composer, WHIP and VRML files, etc.). .Proficient with manual and CNC milling and turning. .Proficient with tensile, hardness, and end-quench hardenability materials testing. COMMUNITY SERVICE: 1/02 -Present, Northfield Village Board of Trustees, Northfield, VT Fall '01 -Present, Northfield Youth Soccer, Northfield, VT Head Coach for ages 4-6. 1/97 -8/97, Cornwall Volunteer Fire Department, Cornwall, VT. Firefighter/First Responder, 12/96 -8/97, Middlebury Volunteer Ambulance Association, Middlebury, VT. Emergency Medical Technician. 2/91 -6/97, Stratford Emergency Medical Service, Stratford, CT Emergency Medical Technician. .Over 2,000 hours of volunteer service in system receiving over 4800 emergency calls annually. .EMT -Paramedic Certification and medical control.