Data Detector:

advertisement

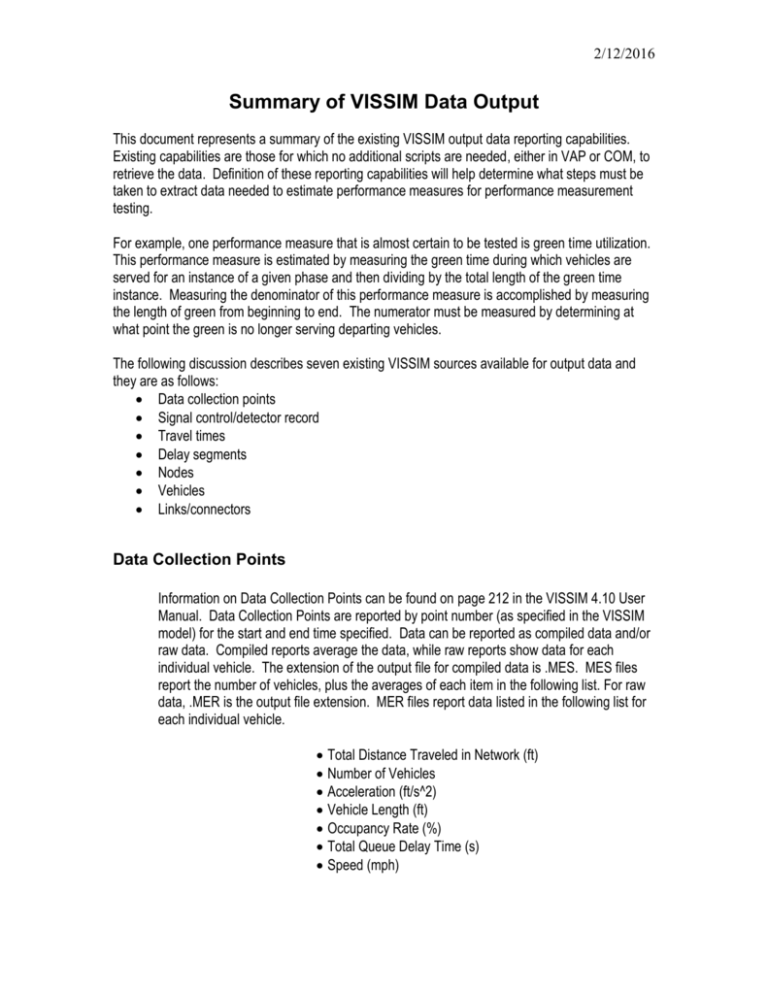

2/12/2016 Summary of VISSIM Data Output This document represents a summary of the existing VISSIM output data reporting capabilities. Existing capabilities are those for which no additional scripts are needed, either in VAP or COM, to retrieve the data. Definition of these reporting capabilities will help determine what steps must be taken to extract data needed to estimate performance measures for performance measurement testing. For example, one performance measure that is almost certain to be tested is green time utilization. This performance measure is estimated by measuring the green time during which vehicles are served for an instance of a given phase and then dividing by the total length of the green time instance. Measuring the denominator of this performance measure is accomplished by measuring the length of green from beginning to end. The numerator must be measured by determining at what point the green is no longer serving departing vehicles. The following discussion describes seven existing VISSIM sources available for output data and they are as follows: Data collection points Signal control/detector record Travel times Delay segments Nodes Vehicles Links/connectors Data Collection Points Information on Data Collection Points can be found on page 212 in the VISSIM 4.10 User Manual. Data Collection Points are reported by point number (as specified in the VISSIM model) for the start and end time specified. Data can be reported as compiled data and/or raw data. Compiled reports average the data, while raw reports show data for each individual vehicle. The extension of the output file for compiled data is .MES. MES files report the number of vehicles, plus the averages of each item in the following list. For raw data, .MER is the output file extension. MER files report data listed in the following list for each individual vehicle. Total Distance Traveled in Network (ft) Number of Vehicles Acceleration (ft/s^2) Vehicle Length (ft) Occupancy Rate (%) Total Queue Delay Time (s) Speed (mph) 2/12/2016 To use Total Queue Delay Time, the definition of a queue needs to be set up within VISSIM. There are default values, but these should be checked and/or modified to correctly use the queue data collection. To set the queue definition, select Evaulate then Files…, then check the box for “Queue Length” and press the “Configuration” button. The beginning and ending velocities of when a vehicle can be considered in queue can be defined from the dialog box. Also the maximum headway and maximum length for which these velocity conditions control can be defined in the dialog box. Signal Control/ Detector Record The VISSIM 4.10 User Manual documents Signal Control/ Detector Record usage on page 232. The Signal Control/Detector Record is reported for the whole simulation time. For the report, the user can select which detectors or signals for which the data are needed. The output reports the signal or detector for which information is being reported and the following output data (.LDP extension): Simulation Seconds Signal Display Status Detector Status The Signal Display is indicated by ( I ) for Green, ( / ) for Yellow, ( . ) for Red. The Status of the Detector is indicated by ( I ) for Occupancy, ( + ) for Presence, and ( . ) for Off. Occupancy is true when the detector is active for the whole simulation second. Presence is true when a vehicle passes over the detector during a simulation step. Travel Times Travel Time is discussed on page 206 in the VISSIM 4.10 User Manual. The output is available in compiled (.RSZ) and/or raw data (.RSR) formats. Both formats specify the travel time section (as specified in the VISSIM model) and the start and end location. Compiled data reports include the following: Average Travel Time (s) No. of Vehicles Raw data reports travel time for each vehicle. Delay Segments 2/12/2016 Delay can be found for a selected travel time section as documented on page 210 of the VISSIM 4.10 User Manual. The output is available in compiled data (.VLZ) and/or raw data (.VLR) formats. Both formats specify the travel time section (as specified in the VISSIM model). Compiled data contain the total number of vehicles and the average data for the following list. Raw files report data from the following list for each vehicle. Delay (s) Stopped Time (s) Number of Stops Nodes By defining a node, VISSIM creates travel time zones and delay segments based on the node boundaries. VISSIM also creates queue counters at each entry node boundary. Therefore, a node can be used in place of defining multiple travel times and delay segments and is much more efficient. Node reports can be generated over a specified start and end time. All records for nodes are stored in files with a .KNA extension. More information about nodes can be found in the VISSIM 4.10 User Manual on page 242. The following data can be collected for nodes: Start Time of the Aggregation Interval (s) End Time of the Aggregation Interval (s) Node Number Movement (Bearing from – to) From Link To Link Number of Vehicles Average Delay (s) Average Stopped Delay (s) Average Number of Stops Average Queue Length (ft) Maximum Queue Length (ft) To use Average Queue Length and Maximum Queue Length, the definition of a queue needs to be set up within VISSIM. To set up the definition of a queue please refer to the “Data Collection Points” section in this document. 2/12/2016 Vehicles Vehicle reports are generated for a specified start and end time. Data can be collected for an individual vehicle, some vehicle types, or all vehicles. The data is stored in a .FVP file. More about vehicle data collection can be found on page 222 of the VISSIM 4.10 User Manual. The data that can be collected for vehicles are: Acceleration (ft/s^2) Following Distance (ft) Vehicle Length (ft) Link Coordinate at the end of the simulation step (ft) Link Number Total Number of Stops Number of the relevant preceding vehicle Total Number of Queue Encounters Total Queue Time Thus Far (s) Queue Flag ( + = yes, - = no) Simulation Time Speed (ft/s) Total Distance Traveled in Network (ft) Total Time in Network (s) Vehicle Number Vehicle Delay (s) Vehicle Total Stops Vehicle Time in Network (s) To use Total Number of Queue Encounters, Total Queue Time Thus Far, and Queue Flag, the definition of a queue needs to be set up within VISSIM. To set up the definition of a queue please refer to the “Data Collection Points” section in this document. Links/Connectors Link/Connector reports are generated for a specified start and end time Data can be collected on a lane of a specified link or connector or it can be collected for multiple links and connectors using mutli-select mode. The data is stored in a .STR file. More about link and connector data collection can be found on page 238 of the VISSIM 4.10 User Manual. The output file reports the lane number and the link or connector number for which the data were collected. The following information is available from link/connector data collection: Vehicle Density (veh/mi) Lane Number Link Number Relative Lost Time (s/s) 2/12/2016 Segment Length (ft) Simulation Time (s) Average Speed (mph) Volume (veh/hr) Using VISSIM Output for Performance Measurement Green time Utilization Given the VISSIM output data capabilities, the supporting data for green time utilization are as follows: Raw actual green time Raw vehicle departure times These data can be retrieved from the “Signal control/detector record” file, using the signal status to determine if the indication is green and then measuring its length and the detector status to determine if a vehicle is departing (i.e., the detector is “on”). Phase Failure Phase failure is defined as a phase not serving all vehicles which were present at the beginning of the phase. The data needed to determine whether a phase fails are: Time Queue Flag Vehicle Position Signal Record The data for time, vehicle position and queue flag can all be gathered from the Raw Vehicle Data. The Signal Record can be found from the Signal Control/Detector Record. In looking at the Signal Record, the beginning of the phase can be determined from where the signal changes from red to green (end of red). The vehicles which are in queue at that time can be determined from the Vehicle Data. If one or more of the vehicles are in queue before the signal at the end of the phase (beginning of red), then the phase has failed. Conclusion VISSIM output capabilities were reviewed and seven options were found. Many of these options will prove useful for obtaining performance measures that can be used for testing performance measurement capabilities found in existing controllers, controller software, and traffic control software. 2/12/2016 A description of how these VISSIM output data can be used for obtaining performance measures was given for a variety of performance measures. In general, it was found that although the data are available, some performance measures will require significant VISSIM output data processing. In most cases, this processing would be labor intensive, making the option of developing scripts or macros to automate the processing more attractive.