Instruction for measurement preload

Sort Criteria #1

Sort Criteria #2

Type of document

Valid From

Segmented Mold Standards PLT

Preload

Work Document

01 June 2015

Mold Management Tires

Mold Engineering

Issue:

Author:

Department:

Release-No.:

7

Wenzel

MMT ME

MMT_ME_213

Preload Measurement with Mold

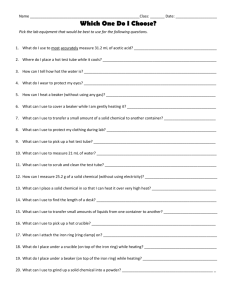

Basic conditions:

Room temperature:

Equipment Tooling:

20° Celsius

Depth gauge with electronic display.

Reading accuracy = 0.03 mm

Squeeze according to drawing no.: H2_C1000_109/…

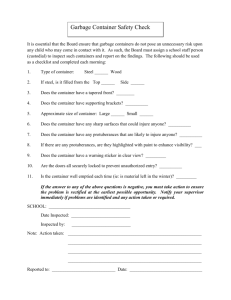

The container has to be:

cleaned

all sharp edges removed

lubricated with exception of “lube free containers”

The top container plate has to be flat (0.1 mm)

Activities:

1.) Assemble mold parts in the container

2.) Container has to be placed on a preload table.

3.) Unscrew shipping bolts.

4.) Lift cone ring so that the segments slide down.

5.) Lower the top container parts onto bottom container plate.

Before fixing the mold segments place shims (total gap/9) between all segment gaps.

Then lower the cone ring so that the segments move into the proper position. Then lift the cone ring, fix the segments and remove the shims.

6.) Ensure that the cone ring has equal contact to each of the tread shoes.

Check with the depth gauge the clearance between the top surface of cone ring and the top container plate at the identifie d points on drawing no.: H2_C1000_109/… In order to avoid that the cone ring tilts, increase the squeeze (maximum 0.05mm per step) at the point where the largest clearance is. Then check the clearance at all points again and increase the squeeze further

(maximum 0.05mm per step) at the point with the largest clearance until 50 kN is reached at the four specified points (total load 200 kN = 4 x 50 kN).

7.) When a total load of 200 kN (

10 kN) is reached, measure the preload between the top surface of the cone ring and the top container plate at 4 equally distributed spaces over 360°. All readings have to be within tolerance of 0.2 -0/+0.1 mm. The range of the readings must be

0.07 mm.

8.) Repeat steps 4.) to 7.) for a second measurement. When all readings are in tolerance, the preload check is correct. Enter the average of the 8 readings in the Inspection Report MMT_ME_504 .

9.) If the preload is not within tolerance, then repeat the preloading measurement with a simulator ring. ( see MMT_ME_212)

If the preload is not within tolerance while using the simulator, then correct the container.

If the preload is within tolerance while using the simulator, then check the mold inserts according to work instruction MMT_ME_210.

Revision History:

Rev. Nr. Description Done by: Date:

Rev 5: Change header and document number.

Rev 6: Minor changes

Rev 7: Measurement procedure detailed

M. Hassellöf

M. van Biljon

A. Huaipar

01-09-2004

01-11-2005

20-05-2015

726964589

Book 2 Mold Manual Page 1 of 1