REFERENCES:

advertisement

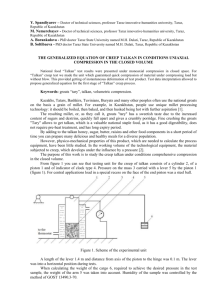

CREEP OF METALS AND ALLOYS COURSE DESCRIPTION: - Total credits: 2 Instructor: Dr. S.M.K. Hosseini Time and location: Every Sunday, 13-15 pm, Faculty of Engineering, Room # 301 INTRODUCTION: The slow deformation of metals, known as creep, first came clearly into focus about half a century ago. As a problem in metal use it has grown steadily in importance because engineers have persistently raised their operating temperatures in many fields, until now it is one of the half-dozen most important of these problems. Besides the abundance of technical data that has necessarily been accumulated, there have been many studies in the last fifteen years of the physics of creep, and it is with these that this article is concerned. These physical studies have shown that there are several different creep régimes depending mainly on the temperature. If TM is the melting point of the metal in question, the different régimes roughly cover the temperature ranges 0-0·3 TM, 0·3-0·5 TM, 0·5-0·9 TM and 0·9-1·0 TM. The bottom range includes the so-called logarithmic creep and the top range creep by diffusion, which is somewhat similar to flow in liquids. Both are quite well understood but neither is particularly important and they are dealt with briefly. It is the middle two temperature ranges in which creep worries engineers; they have therefore received much more attention and the creep behaviour in them is described more fully in this course. In both of these temperature bands the rate of creep strain is very dependent on temperature, stress applied and composition of the metal. The temperature dependence is no surprise, since it is quite clear that creep is a thermally activated phenomenon and its rate is therefore governed by an Arrhenius factor. In many pure metals the temperature dependence is quantitatively close to that of self-diffusion, particularly in the 0·5-0·9 TM band, and the agreement grows better the more refined the measurements become. In the last ten years this result has guided most theories, and has encouraged attempts to be made with partial success to calculate the absolute rates from first principles. Calculations have been founded on both the two basic theoretical models. One assumes that the factor controlling creep rate lies in the deformation process, or glide movement of dislocations, itself. The other assumes that the rate-controlling factor lies in the continuous annealing that takes place at the high temperatures involved. The two models are really two sides of the one penny, since both slip and recovery take place simultaneously and are unavoidably interconnected. When the two models are properly joined they explain the influence of composition, which may affect creep rate by well over a millionfold, and the great influence of stress as well as the temperature effect. The physics of creep deformation in the middle temperature ranges is therefore quite well understood. Indeed, the important parameters like diffusion rate, stress and stacking fault energy combined in a single equation give the creep rates of many simple metals with fair accuracy. A consequence of the growing success in producing alloys that deform very slowly even at high stress and temperature is that the problem of creep fracture has loomed larger. There is a fracture mechanism quite distinctive to creep, in which tiny holes nucleate and grow by some means until they are so large, or sufficiently linked together, that the metal breaks. The speed of this fracture process increases with temperature and stress, and evidently also depends on composition in a complicated way, which has made possible a certain degree of manufacturing control if not of understanding. In essence, the formation and growth of the holes is a phase change in which stress provides the driving free energy since the holes enlarge the overall dimensions. Both the nucleation and growth rates help to determine the time to fracture, which is what really matters. There are several obscure points such as the nature of many of the nucleating sites and the strong influence of deformation rate during nucleation and growth. Both theoretically and practically, understanding of the youthful problem of creep fracture is less mature than that of the older problem of creep deformation. OUTLINE: - - Introduction and definitions (1 session) Creep test and creep data illustration (1 session) Effects of temperature and stress on creep rate (1 session) Deformation Mechanisms Map: Power-law creep and power-law creep breakdown, Diffusional creep, Harper-Dorn creep, Grain boundary sliding (GBS) (4 sessions) Creep damage mechanisms and fractography of fracture surfaces (1 seesion) Creep-life assessment: Larson-Miller parameter, Sherby-Dorn, Manson-Hafferd, etc. (2 sessions) Creep Fracture (1 seesion) Creep/Fatigue/Environmental Interactions (1 session) High-temperature and creep-resistant materials (2 sessions) REFERENCES: 1) 2) 3) 4) 5) 6) 7) 8) Fundamentals of Creep if Metals and Alloys, M.E. Kassner, 2nd ed., Elsevier, 2007 Creep of Metals at High Temperatures, P. Greenfield, Mills & Boon, 1972. Physics of Creep and Creep-Resistant Alloys, F.R.N. Nabarro, N.R. Nabarro, 1st ed. Taylor and Francis, 1995. Creep Mechanics, Josef Betten, 2nd ed., Springer, 2005 Design for Creep, R.K. Penny and D.L. Marriott, 2nd ed. Chapman and Hall, 1995. Mechanical Metallurgy, G.E. Dieter, 2nd ed., McGraw-Hill Book company, 1988. Creep-Resistant Steels, F. Abe, T-U. Kern and R. Viswanathan, 1st ed., Woodhead Publishing Limited, 2008. D. McLean, “The Physics of High-Temperature Creep in Metals, Rep. Prog. Phys., 1966, pp:29-133 COURSE ASSESSMENT: - Midterm (6 points) Final exam (8 points) Quiz and Homework (2 points) Term Project (4 points)