Practical 6 - A-level chemistry

advertisement

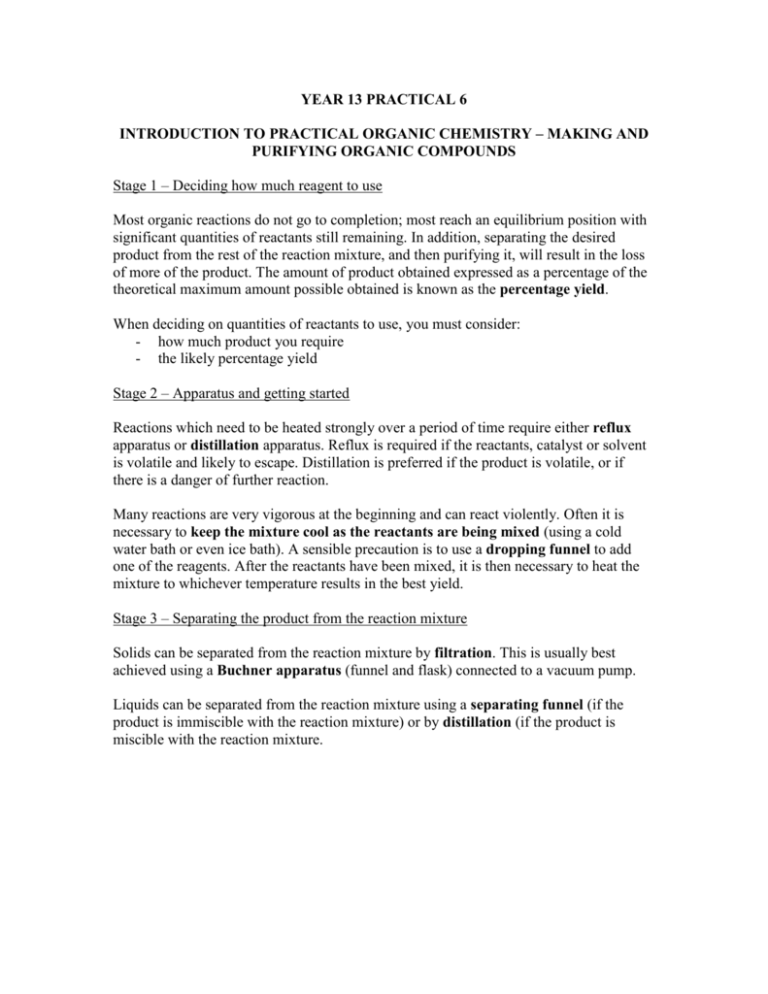

YEAR 13 PRACTICAL 6 INTRODUCTION TO PRACTICAL ORGANIC CHEMISTRY – MAKING AND PURIFYING ORGANIC COMPOUNDS Stage 1 – Deciding how much reagent to use Most organic reactions do not go to completion; most reach an equilibrium position with significant quantities of reactants still remaining. In addition, separating the desired product from the rest of the reaction mixture, and then purifying it, will result in the loss of more of the product. The amount of product obtained expressed as a percentage of the theoretical maximum amount possible obtained is known as the percentage yield. When deciding on quantities of reactants to use, you must consider: - how much product you require - the likely percentage yield Stage 2 – Apparatus and getting started Reactions which need to be heated strongly over a period of time require either reflux apparatus or distillation apparatus. Reflux is required if the reactants, catalyst or solvent is volatile and likely to escape. Distillation is preferred if the product is volatile, or if there is a danger of further reaction. Many reactions are very vigorous at the beginning and can react violently. Often it is necessary to keep the mixture cool as the reactants are being mixed (using a cold water bath or even ice bath). A sensible precaution is to use a dropping funnel to add one of the reagents. After the reactants have been mixed, it is then necessary to heat the mixture to whichever temperature results in the best yield. Stage 3 – Separating the product from the reaction mixture Solids can be separated from the reaction mixture by filtration. This is usually best achieved using a Buchner apparatus (funnel and flask) connected to a vacuum pump. Liquids can be separated from the reaction mixture using a separating funnel (if the product is immiscible with the reaction mixture) or by distillation (if the product is miscible with the reaction mixture. Stage 4 – Purification of the product Solids are purified by a process called recrystallisation: The solid is dissolved in the minimum possible quantity of hot solvent, specifically chosen so that the solid in soluble in the solvent when hot but not when cold. A few impurities (such as grit) will not dissolve in the hot solvent. These can then be removed, if necessary, by filtering the mixture through a pre-heated funnel. The solution is then cooled to below room temperature using an ice-bath. The pure solid should crystallise out of the cold solution. The solid can be separated by filtration under reduced pressure using a Buchner apparatus. A small amount of cold solvent can be added to wash the crystals. The crystals must then be dried between filter paper, and then placed in an oven to dry completely. Stage 5 – Testing the Purity of the Product A simple method for testing the purity of the product is to carry out a melting point determination. Pure substances melt at a fixed temperature. Impurities cause the product to melt at a lower temperature and over a broader range of temperatures. Melting point determinations are carried out in the following way: Break off around 5 cm of a capillary tube and seal one end in a Bunsen burner. Pack 1 cm of the solid as densely as possible into the sealed end of the capillary tube. Place the capillary tube in the melting point apparatus. Ensure that the apparatus heats up very slowly as the expected melting point of the substance approaches. Record the temperature when the liquid starts to melt and when it finishes melting. Compare the melting point range to the known melting point of the pure solid. A pure sample will melt sharply at a temperature close to the known melting point. Important hazards and safety precautions Organic compounds and reactions are often hazardous. The following table shows some of the typical hazards, and the precaution that needs to be taken as a result: Hazard Reagent is harmful, toxic, or corrosive Reagent is flammable Harmful gas or vapours are produced Precaution Wear safety spectacles Wear gloves Flood affected areas if there is a spillage Avoid naked flames Use a fume cupboard YEAR 13 PRACTICAL 4 INTRODUCTION TO PRACTICAL ORGANIC CHEMISTRY Part 1 – Determining suitable quantities of reagents for organic reactions Part 2 – Purifying a sample of aspirin by recrystallisation Part 3 – Checking the purity of a sample of aspirin This practical consists of three separate parts. The parts can be carried out in any order. PART 1 - DETERMINING SUITABLE QUANTITIES OF REAGENTS FOR ORGANIC REACTIONS 1. 2. 3. The reaction between ethanoic anhydride (mr = 102) and 2-hydroxybenzoic acid (mr = 138) to produce aspirin (mr = 180) typically results in a yield of 70% if equal quantities of reagents are used. a) Calculate the mass of 2-hydroxybenzoic acid required to react with 3.5 g of ethanoic anhydride, and calculate the mass of aspirin produced. b) Calculate the mass of ethanoic anhydride and 2-hydroxybenzoic acid required to give 5.0 g of aspirin. 5.0 g of methylbenzene (mr = 92) was mixed with excess concentrated nitric and sulphuric acid to produce 4.7 g of 2-methylnitrobenzene (mr = 137). a) What was the percentage yield? b) What mass of methylbenzene would be required to give 10.0 g of 2methylnitrobenzene, given the same percentage yield? When 3.6 g of benzoyl chloride (mr = 140.5) was mixed with an equimolar quantity of phenylamine (mr = 93), 4.7 g of N-phenylbenzamide (mr = 197) was formed. a) What mass of phenylamine was used? b) What was the percentage yield? c) What mass of phenylamine and benzoyl chloride would be needed to produce 10.0 g of N-phenylbenzanamide, given the same percentage yield? PART 2 – PURIFYING A SAMPLE OF ASPIRIN BY RECRYSTALLISATION 1. Weigh out around of aspirin into a small beaker. 2. Add just enough boiling water to dissolve most of the aspirin. 3. Using a funnel, filter paper and beaker from the oven, filter the solution. 4. Allow the solution to cool in an ice bath. 5. When a reasonable quantity of crystals has formed, filter the mixture again under reduced pressure using a Buchner funnel and flask. Use distilled water to wash all of the contents of the flask into the funnel. 6. Wash the residue in the funnel with a little distilled water. 7. Scrape the residue carefully into another piece of filter paper, and dry by folding the filter paper around the residue and squeezing hard. 8. Place the residue into an evaporating dish and leave in an oven for 10 minutes. PART 3 – CHECKING THE PURITY OF A SAMPLE OF ASPIRIN. 1. Break off around 5 cm of a capillary tube and seal one end in a Bunsen burner. 2. Pack 1 cm of the aspirin as densely as possible into the sealed end of the capillary tube. 3. Place the capillary tube in the melting point apparatus. Ensure that the apparatus heats up very slowly between 115 and 135 oC. Record the temperature when the aspirin starts to melt and when it finishes melting. 4. Pure aspirin melts at 135 oC. Comment on the purity of your aspirin sample.