MODULE 20-ADDENDUM

advertisement

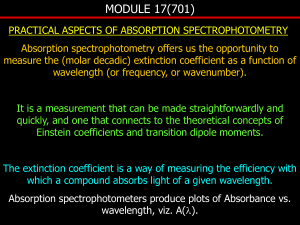

MODULE 17_03 PRACTICAL ASPECTS OF ABSORPTION SPECTROPHOTOMETRY Absorption spectrophotometry offers us the opportunity to measure the (molar decadic) extinction coefficient as a function of wavelength (or frequency, or wavenumber). Thus it is a measurement that we can make relatively straightforwardly in the laboratory that connects to the theoretical concepts of Einstein coefficients and transition dipole moments. The extinction coefficient is a way of measuring the efficiency with which a compound absorbs light of a given wavelength. Absorption spectrophotometers produce plots of Absorbance vs wavelength, viz. A(). And since A( ) ( )[ M ]l where l = path length and [M] = molar concentration of the absorber, for a given concentration and path length, ( ) A( ) Other good reasons for measuring an absorption spectrum are that (i) it can contain information about the vibrational progression in excited states, (ii) it provides information as to where the compound has a high value of and thereby at which wavelength photoexcitation can be optimally carried out, and (iii) it leads to knowledge of the number/rate of photons absorbed for a given incident photon flux (via I a I 0 (1 10 A ) ). Instrumentation There are two principal types of machines that are available on the commercial market, scanning and diode array instruments. A schematic diagram of a scanning instrument is shown in Figure 17.1. The lamp is a composite source, usually a D2 lamp for UV light and a quartz-halogen source for the visible and the near IR. The monochromator is nowadays based on a grating, which disperses light through narrow lines ruled on the surface; see the following hyperlink www.acton-research.com . The bandwidth (the spectral width of the emergent beam) of the monochromator is governed by the dispersion of the grating and the width of the exit slit. The monochromatic beam is deflected by a vibrating mirror into one of two paths; reference and sample. Both paths contain cuvettes with either solvent only (reference) or the sample solution. 1 detector Figure 17.1 lamp monochromator sample reference The detector is a photomultiplier tube (PMT)-see Module 19 or the Oriel website for details of construction and operation. Because the vibrating reflector and the positioning and orientation of the intervening mirrors the beam striking the detector is alternately one that has been transmitted by either reference or sample paths. Thus, the output of the PMT is a square-wave voltage signal that oscillates between Vi and Vt, which relate linearly to the transmitted intensities (I values) in the two cuvettes. These voltages are converted into digital format by an analog-to-digital converter (ADC), the output of which is sent to a computer that calculates the absorbance at the operating wavelength according to I i Vi A log log It Vt Then the monochromator grating is moved to another wavelength and the process repeated over and over for the wavelength range chosen. Typically the scan is continuous. The processor then generates a plot of A versus , viz., an absorption spectrum of the sample. In the array-based device the whole of the wavelength range of the lamp is passed through the sample after which it is dispersed in a spectrograph (Figure 17.2). This is a monochromator (essentially) with the exit slit removed. An array detector (e.g. a CCD) is placed at the focal plane of the spectrograph such that the dispersed white light spectrum covers the whole of the array. Thus each pixel (measuring unit) of the detector (typically 512 or 1064 pixels) “sees” a different wavelength of the dispersed light and thus the array simultaneously records intensity of 2 transmitted light at all wavelengths. This is called the Felgett (or multiplex) advantage (see schematic below) and it represents a major increase in the speed of measuring absorption spectra. S light source to computer CCD spectrograph Figure 17.2 Each of the pixels representing a narrow band of wavelengths is read into a computer, which calculates the absorbance at each one. Placing a cuvette filled with solvent in the sample position and repeating the measurement records the reference data. Errors in Absorptiometry In the double beam scanning instrument the detector alternately sees the light beam transmitted by the reference and the sample channels (see diagram below) as the wavelength is changed, 100 %T 0 white = reference (Vi); cyan = sample (Vt) with a white and a cyan amplitude value recorded at each wavelength setting. In actuality the analog-to-digital converter samples the voltage amplitude several times while the instrument is paused at a particular wavelength, as indicated by the red arrows in the sketch below. 3 In the sketch the ADC is measuring 5 times for each half of the cycle, and the average of the five is calculated and stored as a Vi() or a Vt() reading from which A() is computed. The questions facing us are what governs how precisely the device can measure A()? And how accurately can it measure A() at the low end and the high end of the range? The first is a signalto-noise problem and the second is a dynamic range problem. We look at the latter first. Dynamic Range We need to know how the intrinsic error (V) in the measurement of V affects our measurement. To do this we suppose that the intrinsic error in our ADC is 1 mV, and that the reference measurement yields 1000 1 mV. Let us now see how this error is magnified as A increases-see the Table, neglecting all errors except that in Vt. A Vi/Vt Vt ±V/mV Vi/(Vt ±V) Range in A % error in A 0.1 1.26 793-795 1.261-1.256 0.1007-0.0996 0.01 1 10 99-101 9.901-10.1 0.996-1.004 0.8 2 100 9-11 90.91-111.11 1.959-2.026 4 3 1000 0.1*-2 10,000-500 4-2.699 43 * the low value is really zero, but a small positive value has been entered so an A value can be calculated. What this analysis tells us is that for optimum precision we should arrange to measure absorbances in the region of 1. Remember you can always change the path length of the cuvette to bring your measurement in the best range. Signal-to-noise The above Table is a little misleading in that it shows that the error in A improves as A decreases, and it implies that the nearer A is to zero, the more precise will be the result. Unfortunately this is not so because as the absorbance approaches zero, the ADC is being required to take the ratio of two voltages both of which are very close to the same value (1000 mV in our example) and both have 1 mV error on them. This is not an easy thing to do and it turns out that the errors in A go up again as it drops below 0.1. [Using the method of the Table you can show that the % error at A = 0.01 is 8%, and at A = 0.001 it is ~ 40%.] Thus the intrinsic noise in the ADC becomes the cause of the lack of precision. 4 Fortunately we can overcome this to some extent by recognizing that if we increase Vi to a value significantly greater than 1000 mV, to 10 V for example, then our signal-to-noise ratio will also increase by a factor of 10, because the ADC noise remains at 1 mV. Remember that the absorbance measurement is a relative one; we measure ratios of voltages (Vi/Vt) to obtain A, so the absolute values of the voltages are unimportant. Thus if we increase Vi to pull it out of the noise, then we do the same to Vt. The first thought is to add a voltage amplifier after the detector and before the ADC, but to do only this results in minimal gain because an amplifier will amplify the noise in addition to the signal. In addition to amplification we need to require the ADC to take more samples of the voltage on each half cycle at every wavelength, because signal-to-noise increases as the square root of the number of samples (for random noise). Above we showed only five samples per half cycle. If we increase this to 50, say, this improves the signal by a factor of ~3, and so on. Of course the clock rate of an ADC has limits and in order to achieve the goal it may be that you need to increase the time that the instrument dwells at a particular wavelength, viz., scan more slowly. A special kind of amplifier that can be useful in these circumstances is a lock-in amplifier. This device is set to amplify signals that have a given frequency. To employ such a device you need to chop the optical beam at a suitable frequency (say 500 Hz) and then send a synchronous electrical output from the chopper to the reference channel of the lock-in. This tells the lock-in to amplify only those signals that have a 500 Hz repetition rate. Since noise typically has random frequencies, only a fraction of the noise will be amplified. Another way to enhance Vi and Vt is to increase Ii, the optical power of the incident beam V (increase lamp power; open monochromator saturation curve exit slit). This works because Ii/It is fixed for a given value of A, and increasing Ii leads to a corresponding increase in It. Of course there are I limits here because PMT detectors will saturate at high values of cathode illumination. 5