Minutes

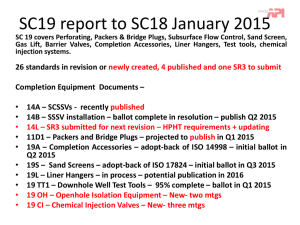

advertisement

API RP 19G13 Meeting on Aug. 30, 2010 Location: Hess’s Offices Downtown Houston The agenda and minutes for the meeting follows: Call to order o The meeting was called to order by Chairman Wayne Mabry at 9:00 am, CDT. Safety briefing o Keith Fangmeier of Hess gave a safety briefing. o Hess provided snacks, drinks, and lunch. Review and acceptance of previous meeting minutes o The minutes were approved. Review of action items and updates o The action items were reviewed. o Wayne Mabry and Cleon Dunham completed their action item on drafting the first section. o John Martinez has reviewed pertinent ISO documents, but hasn’t obtained the documents as yet. o Jim Bennett is working on issues with Flow Assurance. o He questioned the contents of Section 1.0. o Alan Brodie gave some ideas on flow assurance: What are issues that are as a result of gas-lift? How do they occur? How to we mitigate them? Hydrates Where, why, when, operational practices to mitigate? Asphaltines Where, why, when, operational practices to mitigate? Materials and Corrosion CO2 and H2S in lift gas and produced fluids? Material selection. Scales Does having lift gas in the annulus and its insulating properties have an impact on the scaling index in the wellbore? API RP 19G13 Minutes Page 2 Will gas-lifting have a an impact 0on the pressure profile in the wellbore to changes the envelope of scaling indices in the wellbore? Might the composition of the lift gas (e.g. CO2) and the potential for the CO2 to partition into the water phase change the nature of the produced fluids so they become scale forming at other points in the system? Does gas-lifting improve the likelihood of CaCO3 formation? This leads to concerns about when/where to address these issues with chemical injection. We need to provide recommendations with regard to lift-gas entrained chemical injection vs. specific injection points, and what this means with regards to chemical injection valves and gas-lift valves. Emulsions Where, why, when, operational practices to mitigate? Erosion Where, why, when, operational practices to mitigate? Sand Production Where, why, when, operational practices to mitigate? Mitigating slugging because it’s the rate of change of flow rate that is the dominate cause of sand production. Completion Considerations Pressure differentials when place gas in the annulus. Report from each sub-group detailing progress beginning with: o General body of document and comments regarding flow assurance: Cleon Dunham Discussion captured above. Need to focus on how we assure reliability of gas-lift valves through testing for performance, erosion, etc. We will add a section on the type of testing requirements for downhole gas-lift equipment. Need a section on annular safety valves and a barrierqualified check valve in the gas-lift valves. For gas-lift valves, mention of tungsten carbide is too vendor specific. Consideration should be given to defining the acceptable leak rate criteria through gas-lift valves. We don’t want a valve to be a “weak link” in the gas-lift system. Comments on recommendation of tubing size, mandrel size. Discuss recommendations on mandrel “bracketing.” API RP 19G13 Minutes Page 3 Discuss recommendations for use of orifices to achieve critical flow with a lowest Delta P. Discuss chokes downstream of IPO gas-lift valves. Discussion of unloading rate/velocity and quality through the valves. o Land based gas-lift: Ian Schuur Rick Haydel will be part of this team. This will be in the same general section as offshore, dry tree. o Dry tree based gas-lift: Keith Fangmeier For the wellhead recommended practice, follow TLP practice for safety systems. We have a better picture of what the various types of platforms look like. Will discuss issues on monitoring pressures in risers. Keith will forward work he has done to Cleon for inclusion in the draft Master document. o Sub-sea gas-lift: Alan Brodie We will not split high-pressure and normal-pressure sub-sea but combine them into one section. o Highly deviated wells: Mike Juenke Flow assurance issues with slugging in horizontal portion of wellbore. Need work on models used to predict pressure profiles in horizontals. Access issues. o Difficult to intervene: We will enhance the general discussion of intervention in Section 1.0. This topic will also be incorporated into the above four sections. There won’t be a separate section by itself for intervention, so Section 2e will be removed. Review of action items o We want to charge the 17078 ISO Task Group to add a new design verification level (V0) for more stringent testing of barriers for gaslift valves. The recommendation to do this should come from Norway. o Change the wording on the front of the document to be consistent with the wording in Section 2. API RP 19G13 Minutes o The format for the specific sections may follow the format Section 1.0 will not repeat information in the General Section. o Cleon and Wayne will revise Section 1.0 based on today’s discussion. o The authors of the other sections should begin work on their sections. Task Group 19G update o Update of API RP 11V6 on continuous gas-lift mandrel spacing and valves has been approved by API. It will become API RP 19G6. o All ISO gas-lift documents have been or will be adopted back by the API. o An ad-hoc API group has been formed to propose documents to legislative groups. o The API RP 19G11 document will be re-submitted to the Task Group one more time; deadline for return will be Sept. 30. The Work Group will then revise the document again and return a completed document by Oct. 31. The Task Group will consider going to Editorial review. o We want to start a glossary of definitions and abbreviations that are used in all API and ISO documents. o Keith will download all API 11V and 19G gas-lift documents, and compile the definitions and abbreviations. 19G1 19G2 19G3 19G4 11V1 11V2 11V5 11V6 11V7 11V8 19G9 11V10 19G11 19G12 19G13 o We will have an action item for the next Task Group meeting to form a new API RP for gas-lift of gas wells. o John will send me a document needed to propose an API New Work Item. Other business o There was no old business. Page 4 API RP 19G13 Minutes Next Meetings o Next meeting of API RP 19G13 will be Tuesday, Nov. 9, at Schlumberger, on Dairy Ashford. o Next Task Group meeting on Wednesday morning, Nov. 10, at Schlumberger, on Dairy Ashford. o Next meeting of API RP 19G12 will be on Wednesday afternoon, Nov.10, at Schlumberger, on Dairy Ashford. Adjourn meeting o Meeting adjourned at 2:05 pm. Page 5