2788_7711_7146

advertisement

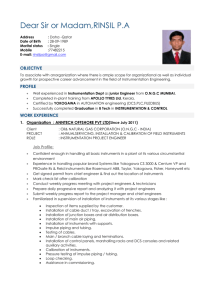

Shanmugam F / 47 C C C Colony Theru Karur (D.T), Puliyur-639114 Tamilnadu, India Email: shanmutn@gmail.com Career Goals: Seeking a management position in Instrumentation engineering with leadership responsibilities including problem solving, planning, organizing & managing budgets. Summary: Possess Nine year of professional experience in Design, Installation & Maintain the equipments for measurements, monitoring and controlling process instrument engineering systems. In-depth knowledge & experience of Metering Instruments & drawings, I/O wiring diagrams, P&ID’s, Instruments calibration and loop testing & commissioning. Extensive knowledge and experience of Process Instrumentation & Control system. Possess excellent co-ordination over verbal and written communication with project team. Ability to troubleshoot and maintaining the instruments for Instrumentation & Control Systems. Highly skilled in Microprocessor & Microcontroller based Instrument & Control system. Job follow up with ISA standards. Extensive knowledge of PLC, DCS & SCADA systems and approaches of metering measurement technologies. Involved in In-plant training program during studies & vendor visit training during project handling. Educational Summary: Bachelor degree in Instrumentation & Control Engineering, Sethu Institute of Technology College from Anna University, Chennai, India in the year (2002 to 2005) with first class. Project work: Simulation of a steam temperature controller using dynamic modeling for a steam generator. Software: MATLAB Status: Group Duration: 3 months Description: In this project there are super heaters between the super heaters there is an attemperator which is used to control the temperature. When super heater temperature is increase the attemperator is used to control it, vice versa. The attermperator is controlled by varying controlled parameters kpi d values, considering the principle of conservation of mass, momentum and energy balance the results were obtained from the dynamic model using MATLAB SIMULINK. Experience: Company name: Babcock Borsig Service, Kuwait Industry: Water distribution network & Subiya Power plant (Kuwait) Position: Instrumentation Engineer (Jan 2011 to till date) Handling the installation, maintenance & troubleshooting activities in the Ministry of Electricity & Water department such as Magnetic flow meters, Ultrasonic flow meters, Pressure transmitters, Ultrasonic level transmitters, Pressure switches, Valve actuators. Pump protection logic control with temperature, vibration monitoring & protection systems for 11 KV 2.5 MW Motors/Pumps in water distribution pumping station. Assigned the projects tasks of replacing / upgrading the Instrumentation & control system & DCS, SCADA. Maintenance of field instruments in boiler, turbine & distillation plant. During shutdown co-operate with the shutdown team. Handling the job responsibilities of Instrumentation & Control system status checking, troubleshooting, Calibration & Commissioning. PLC such as Siemens, ABB, Honeywell troubleshooting with vendor support during maintenance. Study, design & implement the new Instrumentation and control system for Control & Monitoring the pumps, Motor operated valves. Modifying & upgrading the absolute equipments for Instrumentation and control systems. Working collaboratively with Operation & Maintenance Engineers, Design Engineers and other internal staff for completing multiple metering Instrumentation projects. Water distribution network, plant size, fresh water production rate is 400 gallons / day. Overall job report will be updated to project manager. Projects completed from 2005 to 2010: Company name: PT. Euroasiatic Jaya, Jakarta, Indonesia Industry: Power plant project Position: Instrument engineer (Feb 2010 to Dec 2010) Installation, testing & commissioning for the Electrical, Instrumentation & Control work for 20 MW Co-generation power plant projects (PT.South pacific viscose plant, Jakarta, Purwakartha, INDONESIA). Installation works Electrical & Instrumentation Schedule for 20 MW Cogeneration Power plant. Boiler Hydro test. Flushing & leak testing for instruments with impulse tubing. Pre commissioning checks & protocol for Instrumentation. Pre commissioning of all electrical and instrument equipments related to alkali boil out. Arranged related & required Instruments for Chemical cleaning & steam blowing for Boiler Electromagnetic relief valve (safety valve). Implementation of logics & interlocks. Boiler load trial & stabilization. Over all job report will be updated to project manager. Company name: Greenesol power system (p) Ltd, Chennai, India Industry: Power plant project Position: Senior Instrument engineer (Aug 2008 to Jan 2010) Successfully completed testing and commissioning for the Instrumentation & Control work for 260 TPH CFBC Boiler project (M/S. Sanghi cement industries, Gujarat, INDIA) Boiler installation Instruments from Field to DCS. Power cylinder & valve installation. Boiler hydro / chemical cleaning / slow firing / Refractory dry out / steam blowing. Trial run of various boiler auxiliaries like Fan, Motors, Pump etc.. Instrument to DCS Cable laying, termination and testing / loop checking up to DCS. DCS Logics implementation. Respective commissioning activities / Instrument trouble shooting. Successfully completed testing and commissioning for the Instrumentation & Control work for 135 TPH CFBC Boiler project (M/S. Adhunik metallic limited, Rourkela, Orissa, INDIA) Power cylinder & valve installation. Boiler hydro / chemical cleaning / slow firing / Refractory dry out / steam blowing. Trial run of various boiler auxiliaries like Fan, Motors, Pump etc Instrument to DCS Cable laying, termination and testing / loop checking up to DCS. DCS Logics implementation. Respective commissioning activities / Instrument trouble shooting. Over all job report will be updated to project manager. Company name: Chemin C & I (p) Ltd, Pondicherry, India Industry: Aviation fuel form project & Power plant project Position: Senior Instrument engineer (Nov 2006 to Jun 2008) Successfully completed Aviation fuel form project in (M/S. GMR International airport, Shamshabad, Andhra Pradesh, INDIA) Aviation fuel form site Instrumentation installation, testing & commissioning. Successfully completed 1 X 500 MW Power plant project in (M/S. MPPGCL, Birsinghpur, Madhya Pradesh, INDIA) Installation work for Instrumentation schedule for PC fired boiler power plant. Installation of Local Instrument enclosure, Local Instrument rack, JB & FIELD Instruments. Cable laying, termination, testing & commissioning from DCS to Switch gear and field Instruments. Simulation, calibration and testing of all field instruments as per required commissioning. Over all report will be updated to site manager. Company name: Karuna enterprises, Andhra Pradesh, India (May 2005 to Oct 2006) Industry: Pulp & Paper plant project Position: Instrument supervisor Successfully completed pulp & paper plant project in (M/S. APPM, Kothagudem, Andhra Pradesh, INDIA). Installation of all field instruments. Area of Interest: From my working position for certain task I want to take me to senior position. Design & install Instrumentation & DCS, SCADA Systems for various Instrumentation field to cover a range of data for evaluation programs. Personal details: Name: M.Shanmugam Fathers name : M.P.M.Muthiah Nationality : Indian Status : Married Passport number : L1432662 Date of issue : 02/09/2013 Date of expiry : 01/09/2023 Date of Birth: 05/10/1983 Contact number : +965-96954635 By M.Shanmugam