Overview - Documents & Reports

advertisement

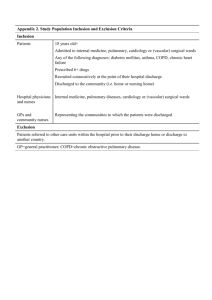

E2813 v16 【China: GEF Dioxin Reduction from the Pulp and Paper Industry Project(P125528)】 Environmental Management Plan For Technical Upgrade of Jinfu Paper Mill (Sichuan Jinfu Paper Co., Ltd) January 2012 Contents OVERVIEW ........................................................................................................................................... 2 1. ENTERPRISE OVERVIEW ................................................................................................................ 3 2. AIMS OF AND STANDARDS OF ENVIRONMENTAL PROTECTION ..................................................... 11 3. ENVIRONMENTAL PROTECTION MANAGEMENT PLAN .................................................................. 16 4. ENVIRONMENTAL MONITORING PLAN ......................................................................................... 27 5. STAFF TRAINING ......................................................................................................................... 29 6. ESTIMATED EXPENSES FOR ENVIRONMENTAL MANAGEMENT PLAN ............................................. 30 7. INFORMATION EXCHANGE .......................................................................................................... 32 8. RECORD ...................................................................................................................................... 33 9. REPORT ....................................................................................................................................... 34 1 Overview This environmental management plan was prepared on the basis of “Environmental impact report of 52 thousand t/a of paper pulp, 57 thousand t/a of paper products and related equipments of Sichuan Jinfu Paper Co., Ltd”, “Environmental impact report of energy-conservation and technology upgrading project of Sichuan Jinfu Paper Co., Ltd” and “Environmental impact report of energy-conservation and technology upgrading project concerning pulp system of Sichuan Jinfu Paper Co., Ltd” and provided with appropriate supplements. This environmental impact report of is a separate document, including all environmental protection actions need to be implemented during project design period, construction period and operation period, providing an action principles and working framework for implementing discharge reduction measures, environmental protection and environmental monitoring during construction period and operation period. This report includes following main contents: *Project overview *Project’s potential environmental impact *Departments and responsibilities *Environmental management plan *Environmental monitoring plan Purpose of this environmental management plan The pulp and paper production equipments of Sichuan Jinfu Paper Co., Ltd aim to reduce the negative impact of enterprise’s production on society and environment through high-quality design and construction as well as strict environmental evaluation, and resolve the left environmental problems through environmental measures. As of the inevitable environmental impact, one major purpose of environmental evaluation is to determine the potential impact of project on environment and propose technically feasible, finically sustainable and operable environmental measures implemented during project construction and operation period. These environmental measures have been determined during environmental evaluation phase, will be proposed reasonably and feasibly in environmental management plan and applied during project construction and operation period. The function of environmental management plan is to list environmental measures need to be implemented during project construction and operation period as well as the measures taken by in monitoring and department level, thus to avoid or control the negative impact of this project on environment and propose specific actions to implement these measures. Environmental management plan will become an important link between environmental measures and actions determined in environmental impact and environmental evaluation, and achieve the aims of environmental measures through actions in environmental management plan. 2 1. Enterprise overview 1.1 Enterprise development, current situation and origin of technology upgrading Sichuan Jinfu Paper Co., Ltd (hereinafter referred to as “Jinfu”) is a private business with its plant located at Tangjiawan, Fulu Town, Shwan District, Leshan city, occupying 12.13 hectare (182 Mu). The total asset of the enterprise is 250 million RMB. It was called as Leshan bathroom tissue Plant, Fulu Branch before 1999. In 1999, Sichuan Fuhua Group purchased this plant and changed its name to Sichuan Leshan Fuhua Paper Co., Ltd. Its name again changed to Sichuan Jinfu Paper Co., Ltd after reorganization and restructuring in 2009. Jinfu’s production capability is 52 thousand t/a of bleached bamboo pulp and 57 thousand t/a of paper products. All produced bleaching bamboo pulp is used by itself without selling out. The major products of the enterprise are bleached pulping paper board, cultural paper, and bathroom tissue, etc. Jinfu’s production capability reached the scale of 52 thousand t/a of pulp and 57 thousand t/a of paper products in 2004, and then Jinfu became a pulp and paper enterprise with facilities of chemical pulp making, paper making, soda recycling, medium waste water treatment, white water recycling etc. Its environmental evaluation report was replied by Sichuan Environmental Protection Bureau in 2010 (Chuan Huan Shen Pi [2010] No. 479). Now Jinfu is conducting the construction of “energy-conservation, discharge reduction and technology upgrading project” as well as “energy-conservation, discharge reduction and technology upgrading project concerning pulp system”. These two projects were recorded in Leshan economy and information committee. And the environmental evaluation of “energy-conservation, discharge reduction and technology upgrading project” is replied by Leshan environmental protection Bureau (Le Shi Huan Shen [2011] No. 26). The “energy-conservation, discharge reduction and technology upgrading project concerning pulp system” is undertaking its environmental evaluation work. The above two upgrading projects will fully improve the whole production technique of Jinfu, promote the Clean Production of Jinfu to a new level to reduce energy and material consumption, thus to eventually make sure the discharged waste water meeting the discharge limit in table 2 pulping and paper making joint enterprise in GB 3544-2008 which entered into effect on 1st July 2011. Meanwhile, the two project will effectively reduce the POP in waste water such as AOX and Dioxin, etc, as well as the generation and discharge of odor pollutants special to paper making industry. In addition, this project will eliminate environmental risks caused by use of liquid chlorine. 2.1 Enterprise’s project composition and major technical indicators Enterprise’s current situation Jinfu uses bamboo chips to make pulp and applies the methods of dry raw material preparation, sulphate low energy consumption Intermittent cooking-ball cooking system, vacuum pulp washer suite to wash pulp, pressure screening, medium concentration sand remover to purify and low chlorine four-stage bleaching. 3 Jinfu uses a multi-cylinder long mesh paper machine with breadth of 1760 mm and working speed of 200 m/min to produce cultural paper, and 11 tissue paper machines with breadth of 2200 mm and working speed of 180 m/min to produce bathroom tissue paper Jinfu uses five-effect evaporators to evaporate, concentrate, combust, causticize and recycle soda. The white sludge is sent to slag yard of the enterprise for landfill. There is a 35 t/h circulating fluidized bed coal-fired boiler, a 8 t/h and a 6 t/h chain boilers, with the total low-pressure steam production capability of 49 t/h in boiler room. The waste water station uses “ABR + contact oxidation” two-stage biochemical treatment technique to treat medium waste water, excessive white water, householdwaste water and floor wash water, reaching the treatment capacity of 20 thousand t/d. The treated waste water is discharged to Dadu River through pipelines after meeting the requirements in table 1 “pulp and paper enterprises” of “Discharge standard of water pollutants for pulp and paper industry” (GB3544—2008). The smoke from boiler is discharged through chimney of 50 m after furnace desulfuration and electrostatic precipitation of 3-electric field. The smoke from soda furnace is discharged through chimney of 80 m after electrostatic precipitation of 3-electric field. The enterprise set a sanitary protection zone of 100m wide for the non-organized discharge of odorous pollutant from pulp making. Refer to table 1.1 for current project composition and major environmental problems. Table 1.1 current project composition and major environmental problems Item Name Material storage yard and material preparation Main part Pulp making workshop Content Major environmental problems during operation This project uses dry raw Waste bamboo slag, material preparation: fermentative gas purchase qualified bamboo chips stored in material storage yard of 4500m3and sent to cooking workshop after selection and screening. Pulp making capacity: 52 thousand t/a; black liquid from pulp 1) cooking-ball: making, medium waste 10×25m3; water, steam from 2) vacuum pulp washer cooking, bamboo slag suite for black liquid after section removal, collection potential leakage risk of 3) pressure screening chlorine used for and purification bleaching 4) CEHP four-stage bleaching 4 Major environmental protection measures during operation Waste bamboo slag is sent to boiler for combustion. black liquid from pulp making is sent to soda recycling workshop for combustion; medium waste water is sent to waste water station for treatment and discharge, steam from cooking is discharged directly, bamboo slag after section removal is sent to cooking-ball. There shall be an emergency soda pool for potential leakage risk of chlorine used for bleaching Soda recycling workshop Evaporation: two suits of five-effect pipe and board combined evaporator with the total evaporation area of 4250m2 Combustion: combustion capacity of soda furnace is 225tds/d with the side product of 1.27MPa steam of 25m3/h Digestion and causticization: including green liquor clarifier, continuous causticizer, white liquor clarifier, white sludge washer. Smoke from soda furnace combustion is discharged through chimney of 80 m after Smoke from soda furnace three times of electric dust removal, water combustion, water vapor vapor from dissolving tank of soda furnace from dissolving tank of is discharged through exhaust-funnel of soda furnace, evaporated 35m, evaporated non-condensable gas is non-condensable gas, discharge after absorption of seal water at white sludge, lime slag, the outlet of vacuum pump, white sludge cool waste water from and lime slag are sent to slag yard for black liquor evaporation, landfill, cool waste water from black liquor water seal water at the evaporation is sent to waste water station outlet of vacuum pump for treatment, water seal water at the outlet of vacuum pump is sent to waste water station for treatment. Production capacity: 57 thousand t/a, including 14 Paper making production lines of White water from paper workshop bathroom tissue, pulping machine, damaged paper paper board and cultural paper Boiler room Auxiliar y public and environ mental protectio n facilities Water treatment station Total production capacity is 1.27MPa steam of 49 t/h: including a 35 t/h circulating fluidized bed boiler, a 6 t/h and 8 t/h chain boiler. Equipped with diesel-driven generator Dry coal shack: a day coal shack of 2500m2 Lime ash yard: the ash yard is equipped with dust remover, the ash is directly moved outside at the outlet of yard after temporary storage. A suit of 25 t/d water softening device is equipped at soda recycling workshop; another suit of 49 t/h water treatment device is equipped at boiler room. The technique of ion-exchange resin tower is used. White water from paper machine is largely used for washing and screening after white water recycling and treatment, excessive white water is sent to waste water station and discharged. Damaged paper is recycled after changed to pulp in this workshop. SO2, smoke, boiler slag, lime ash, noise of fans Furnace desulfuration in circulating fluidized bed boiler, the smoke from boiler is discharged through chimney of 50 m after three times of electric dust removal. Boiler slag and lime ash are sold to cement plant Coal dust A barricade and spray method are used as dust falling measures. Dust Move ash outside in time to reduce the discharge of dust. Waste water from boiler, and waste water from Sent to waste water station resin regeneration 5 There is a suit of air compressed air compression preparation device to Equipment noise station provide instrument air in paper making workshop. transformer Power supply facilities / substation Treat medium waste water, cool waste water from black liquor evaporation, excessive Waste water Tail water, sludge, white water from paper odorous pollutants station machine, household waste water and floor wash water White sludge yard Liquid chlorine Storage storage facilities Finished product storage Staffs in plant Sound insulation and shock absorption / Waste water is discharged after meeting the requirements “Discharge standard of water pollutants for pulp and paper industry” (GB3544—2008). Sludge is moved outside and a sanitary protection zone of 100m wide is set. There is a ash yard at Huangnipo village which Risk of underground Seepage-proofing. is 4 km from the project water pollution. for white sludge landfill. There is a storage to store There is an emergency soda pool and 50 liquid chlorine steel Risk of chlorine leakage positive-pressure gas mask bottle of 1 t/bottle Storage room for finished paper rolls and bleached / / pulping paper board Household waste water is sent to waste Household waste water water station and household garbage is sent Workshop and office and garbage to dumping sites designated by environmental protection departments Refer to table 1.2 for current pollutants discharge of Jinfu. Table 1.2 current discharge situation of “three wastes” of Jinfu Item Medium waste water Source intensity at generation Amount of waste water: 8797.5t/d CODCr:1100mg/L、3290t/a Cool waste water from soda Amount of waste water: 1071t/d recycling CODCr:1000mg/L、364t/a Waste water Source intensity at discharge White water from paper Amount of waste water: 994.5t/d machine (left after recycling) CODCr:150mg/L、51t/a Waste water from boiler room Amount of discharged water: 29t/d and resin regeneration water Amount of waste water: 11017t/d CODCr:150mg/L、562t/a BOD5:30mg/L、112.4t/a SS:50mg/L、187.3t/a NH3-N:10mg/L、37.5t/a householdwaste water and floor Amount of waste water: 125t/d CODCr:350mg/L、15t/a wash water Smoke from 49 t/h coal-fired boiler (discharge through exhaust-funnel of 50 m) Waste gas Smoke from soda furnace (discharge through exhaust-funnel of 80 m) Total Amount of smoke: 55 thousand m3/h SO2:1080mg/m3,485.2t/a Dust:13000mg/m3, 5834.4t/a Amount of smoke: 54 thousand m3/h Dust: 15500mg/m3,6833t/a SO2:4.5mg/m3、2t/a SO2:487.5t/a Dust:12667.4t/a 6 Amount of smoke: 55 thousand m3/h SO2:700mg/m3,314.2t/a Dust:130mg/m3, 58.3t/a Amount of smoke: 54 thousand m3/h Dust: 155mg/m3,68.3t/a SO2:4.5mg/m3、2.0t/a SO2:316.2t/a Dust:126.6t/a White sludge and lime slag Solid waste 52 thousand t/a(50% wate) Coal ash from boiler 38500t/a Bamboo slag from material preparation 3276t/a Slag yard for landfill Sold to cement plant for comprehensive utility Sold to fibre-board plant for comprehensive utility Lime slag Sludge from waste water station Section slag from cooking 2600t/a Moved outside for landfill 2000t/a Slag yard for landfill 1600t/a Sent back for cooking Pulp slag from screening 1590t/a Combusted in boiler Damaged paper 500t/a Recycled at the same workshop Waste package material 200t/a Recycled by supplier Householdgarbage 50t/a Moved outside for landfill 102346t/a 44.7% is utilized comprehensively and the other 55.3% is treatment s landfill Total 3.1 The production situation after technology upgrading The production techniques of Jinfu shall be as following after these two technology upgrading projects are finished: Pulp making will applies wet material preparation, low energy consumption Intermittent Displacement Digester System, medium concentration section removal, vacuum pulp washer suite for pulp washing, medium concentration sealed screening and medium concentration and chlorine dioxide three stage bleaching system. The preparation of chlorine dioxide applies SVP-LITE (R8 method). Jinfu uses a multi-cylinder long mesh paper machine with breadth of 1760 mm and working speed of 200 m/min to produce cultural paper, and 11 tissue paper machines with breadth of 2200 mm and working speed of 180 m/min to produce bathroom tissue paper. As of soda recycling, Jinfu uses 225tds/d medium-pressure and low-odor soda furnace equipped with excessive heat power generator. It uses five-part five-effect all board evaporator equipped with cool waste water steam collection tower for black liquor concentration. Facilities including green liquor clarifier, continuous causticizer, white liquor clarifier, white sludge washer are used fro soda recycling. The white sludge is sent to slag yard of the enterprise for landfill. There is a 50 t/h medium-pressure circulating fluidized bed coal-fired boiler in boiler room. The waste water station uses “ABR + contact oxidation +deep treatment” three-stage biochemical treatment technique. The treated waste water is reused partly and the remaining is discharged to Dadu River through pipelines after meeting the requirements in table 2 “pulp and paper enterprise” of “Discharge standard of water pollutants for pulp and paper industry” (GB3544—2008). The smoke from boiler is discharged through chimney of 80 m after furnace desulfuration and electrostatic precipitation of 4-electric field. The smoke from soda furnace is discharged together with boiler chimney after electrostatic precipitation of 4-electric field. High-concentration odorous pollutants are discharged after treatment of light and oxygen waste gas purifier. Low-concentration odorous pollutants and waste gas from washing, screening and bleaching are discharged after 7 treatment of Washing spray tower. The enterprise set a sanitary protection zone of 100m wide for the non-organized discharge of odorous pollutant from pulp making. Refer to table 1.3 for project composition and major environmental problems after technology upgrading. Table 1.3 project composition and major environmental problems after technology upgrading Item Name Content Pulp making capacity: 52 thousand t/a; 1) Wet material preparation 2) Intermittent Displacement Pulp Digester: 4×135 m3; making 3) medium concentration oxygen worksho delignification, medium p concentration sealed screening and purifing 4) ECF elemental chlorine free bleaching Main parts Evaporation: five-part five-effect all board evaporator equipped with cool waste water steam collection tower; Combustion: combustion capacity of soda furnace is 225tds/d with Soda the side product of 3.82MPa recycling steam. Equipped with excessive workshop heat power generator and odorous gas is collected after combustion. Digestion and causticization: including green liquor clarifier, continuous causticizer, white liquor clarifier, white sludge washer. Major environmental problems during operation Major environmental protection measures during operation black liquid from pulp making, waste water from bleaching, waste water from material preparation steam from cooking, material preparation slag, bamboo slag Black liquid from pulp making is sent to soda recycling workshop for combustion; medium waste water is sent to waste water station for treatment and discharged, steam from cooking is discharged after collection and treatment, material preparation slag is boiler as fuel. Smoke from soda furnace combustion, water vapor from dissolving tank of soda furnace, evaporated noncondensable gas, white sludge, lime slag, cool waste water from black liquor evaporation, water seal water at the outlet of vacuum pump Smoke from soda furnace combustion is discharged through chimney of 80 m after electrostatic precipitation of 4-electric field, water vapor from dissolving tank of soda furnace is discharged through exhaust-funnel of 35m, evaporated noncondensable gas is discharge after absorption of seal water at the outlet of vacuum pump, white sludge and lime slag are sent to slag yard for landfill, cool waste water from black liquor evaporation is sent to waste water station for treatment, water seal water at the vacuum pump is sent to waste water station for treatment. White water from paper machine is largely used for washing and Production capacity: 57 thousand screening after white water Paper White water from t/a, including 14 production lines of recycling and treatment, excessive making paper machine, bathroom tissue, pulping paper white water is sent to waste water workshop damaged paper board and cultural paper station and discharged. Damaged paper is recycled after changed to pulp in this workshop. 8 A suit of 4 t/d R8 method chlorine dioxide preparation system with the Chemical actual production capacity of 2.75 workshop t/d 10% chlorine dioxide and 3.85 t/d sodium sulfate as side product. Non-condensable gas at absorption tower, cooling water from vacuum jet, leakage risk of raw materials such as sodium chlorate methyl alcohol Empty the non-condensable gas at absorption tower, cooling water from vacuum jet is sent to waste water station, side product of sodium sulfate is sent to soda furnace as raw material for Sodium Sulphide Auxiliary public and environmental protection Boiler room Furnace desulfuration in boiler, the smoke from boiler is discharged SO2, smoke, boiler together with smoke from soda A 50 t/d circulating fluidized bed slag, lime ash, noise furnace through chimney of 50 m boiler, Dry coal shack and Lime of fans, waste water after electrostatic precipitation of ash yard. from boiler 4-electric field. Boiler slag and lime ash are sold to cement plant Water treatme nt station A suit of 30 t/d desalted water waste water from Sent to waste water station device resin regeneration air compre ssion station There is a suit of compressed air preparation device to provide Equipment noise instrument air in paper making workshop. transfor mer Power supply facilities / substati on Treat medium waste water, cool waste water from black liquor evaporation, excessive white water Waste from paper machine, household Tail water, sludge, water waste water and floor wash water odorous pollutants station Storage facilities White sludge yard sodium chlorat e storage Finishe d product storage Sound insulation absorption and shock / Waste water is discharged after meeting the requirements “Discharge standard of water pollutants for pulp and paper industry” (GB3544—2008). Sludge is moved outside and a sanitary protection zone of 100m wide is set. There is a ash yard at Huangnipo Risk of underground village which is 4 km from the Seepage-proofing. water pollution. project for white sludge landfill. Risk of explosion Storage room for finished paper rolls and bleached pulping paper board / Strengthen management according to requirements / Refer to table 1.4 for pollutants discharge situation of Jinfu after technology upgrading. 9 Table 1.4 discharge situation of “three wastes” of Jinfu after technology upgrading Item Medium waste water Source intensity at generation Source intensity at discharge Amount of waste water: 6110t/d , CODCr:1000mg/L Waste water from material Amount of waste water: 1835t/d , preparation CODCr:150mg/L Cooling water from steam Amount of waste water: 157t/d,CODCr: All is sent to waste water station for treatment, W jet pump in ClO2 workshop 100mg/L part recycled water is reused and the remaining as Cool waste water from Amount of waste water: 1376t/d , is discharged into Dadu River. te soda recycling CODCr:800mg/L Amount waste water discharged: 8200m3/d w CODCr:90mg/L、250.9/a at Excessive white water from Amount of waste water: 764t/d,CODCr: BOD5:20mg/L、55.8t/a paper machine 150mg/L er NH3-N:8mg/L、22.3t/a Waste water from boiler room and desalted water Amount of discharged water: 84 t/d station Householdwaste water and floor wash water Amount of waste water: 128t/d,CODCr: 350mg/L Smoke from coal-fired boiler Amount of smoke: 77.6 thousand m3/h SO2:335.3mg/m3, dust: 41.4g/m3 Smoke from soda furnace Amount of smoke: 54 thousand m3/h, dust: 47.5g/m3,SO2 :106 mg/m3, Wa High-concentration odorous Amount of waste gas: 1500m3/h gas from cooking ste gas Low-concentration odorous gas from cooking and Waste Amount of waste gas: 2000m3/h gas from washing, screening and bleaching Sol id wa ste SO2:259.1t/a Dust:94.8t/a NOx:644t/a Discharge through exhaust-funnel of 30 m after meeting standards Discharge through exhaust-funnel of 30 m after meeting standards Tail gas at absorption tower Amount of waste gas: 500m3/h, tiny Discharge through exhaust-funnel of 30 m at ClO2workshop amount of ClO2 and methyl alcohol after meeting standards White sludge and lime slag 54.6 thousand t/a Slag yard for landfill Coal ash from boiler 47.2 thousand t/a Sold to cement plant for comprehensive utility Bamboo slag from material 5720t/a Combusted in boiler preparation Lime slag 2600t/a Slag yard for landfill Sludge from waste water 2000t/a Moved outside for landfill station slag from cooking Section 1600t/a Sent back for cooking Pulp slag from screening 1060t/a Combusted in boiler Damaged paper 500t/a Recycled at the same workshop Waste package material 200t/a Recycled by supplier Household garbage 50t/a Moved outside for landfill 10 2. Aims of and standards of environmental protection 2.1 Enterprise’s aims of environmental protection Aim of environmental protection concerning surface water: the waste accepting water body is Dadu River. The water environment function of the waste accepting section belongs to Level III water and implements Level III water in “Environmental quality standards for surface water” (GB 3838-2002). Aim of environmental protection concerning underground water: the regional underground water implements Level III water in “Quality standard for ground water” (GB/T14848-93). Aim of environmental protection concerning air quality: the air quality near plant shall meet the requirements in “Ambient air quality standard” (GB3095-1996). Specific pollutants such as H2S shall meet the requirements of maximum concentration of air hazardous substance for residential areas in “Hygienic standards for the design of industrial enterprises”(GBE 1-2002) Aim of environmental protection concerning sound quality: the sound quality of the areas where the project is located shall meet the requirements level II in “Environmental quality standard for noise” (GB3096-2008). The air quality in plant and workshops shall meet relevant requirements in “Hygienic standards for the design of industrial enterprises”(GBE 1-2002). 11 Refer to table 2.1 for aims of environmental protection around the enterprise. Table 2.1 list of major aims of environmental protection and social concerns environmental elements Name Surface water Dadu River Underground water Well of farmer Position Protection level Meet the requirements for Level III water in GB 3838-2002 Protect the underground Meet the requirements 60 m on the east of water in the well of nearby for Level III water in waste water station farmers from polluting GB/T14848-93 Approximately 21 thousand N,4km people Approximately 10380 W,0.4km people West of this project Fulu Town Niushi Town Air quality Protection aim Tongci Town N,4.5km Center school of Niushi Town N,10m Approximately 7760 people Meet the Approximately 1000 teacher requirements for and students Level II in Approximately 3 residents GB3095-1996 W,0.4km W,30m Approximately 5-7 residents S,100m 1 residents S,310m 5 residents Nearby farmers Sound quality Meet the requirements for class II area in (GB3096-2008) Ensure that the risks maintain at Area within 3 km away from chemical workshop environmentally acceptable level. 200 m Environmental risks Air From nearby residents It is can be seen from the above table that except for the scattered residents near enterprise, the main environmentally sensitive target of air pollutants is Niushi Town Chang Town opposite to Dadu River and which is 0.5 km away. Environmentally sensitive target of discharged waste water is Fulu Town at the downstream of waste discharge outlet, but people at Fulu Town and Niushi Town have never take water from Dadu River. 2.2 Environmental Quality Standard 1) Air quality The project implement requirement for level II in GB3095-1996. Refer to table 2.2. Table 2.2 air quality evaluation standard unit: mg/Nm3 Item PM10 SO2 Annual mean 0.10 0.06 Daily mean 0.15 0.15 Mean for an hour / 0.50 Standard implemented Level II in GB3095-1996 12 2) Surface water quality Dadu River, the surface water accepting waste water of enterprises implements the requirements for Level III water in “Environmental quality standards for surface water” (GB 3838-2002). Refer to table 2.3. Table 2.3 Environmental quality standards for surface water for Dadu River Item pH Concentration 6~9 limitation (mg/l) Level CODcr BOD5 NH3-N SS Total nitrogen Total phosphorus Sulphide Volatile phenol ≤20 ≤4 ≤1.0 ≤0.05 ≤0.2 ≤0.2 ≤0.2 ≤0.005 Level III in “Environmental quality standards for surface water” (GB 3838-2002) 3) Underground water quality Underground water implements the requirements for Level III water in “Quality standard for ground water” (GB/T14848-93). Refer to table 2.4. Table 2.4 regional Quality standard for ground water Item pH Concentration 6.5~8.5 limitation (mg/l) Level Color degree ≤15 Total Ammonia hardness nitrogen ≤450 Sulphate Volatile phenol Chloride Permanganate Index ≤250 ≤0.002 ≤250 ≤3.0 ≤0.2 Level III water in “Quality standard for ground water” (GB/T14848-93). 4)Sound Quality Sound quality implements requirements for class II area in “Environmental quality standard for noise” (GB3096-2008). Refer to table 2.5. Table 2.5 Environmental quality standard for noise ( GB 3096-2008) Standard value dB(A) Standard and level implemented GB3096-2008 class II area Day Night 60 50 2.3 Discharge standard 1) Water pollutants The discharged water implements the requirements in table 2 of “Discharge standard of water pollutants for pulp and paper industry” (GB3544—2008) (entered into force on July 1st 2011). 13 Refer to table 2.6. Table 2.6 “Discharge standard of water pollutants for pulp and paper industry” (GB3544—2008) unit mg/L Discharge standard Amount of discharged water pH CODCr BOD5 SS Ammonia nitrogen Total nitrogen Total phosphorus Color degree AOX GB3544-2008 ≤60 6~9 ≤90 ≤20 ≤50 ≤8 ≤0.8 ≤12 ≤50 times ≤12 Note: in above standard, there is no dimension for pH and the unit for amount of discharged water is t/ t of product (pulp). 2) Air pollutants Smoke from boiler implements requirements for period II of class II area in “Emission standard of air pollutants for coal--burning oil- burning gas-fired boilers” (GB13271-2001). Smoke from soda furnace implements the requirements for level II in “Emission standard of air pollutants for industrial kiln and furnace” (GB9078-1996). Waste gas (odorous gas) implements the requirements for level II in table 1 in “Emission Standard for Odor Pollutants” (GB14554-93). Refer to tables 2.7 to 2.9. Table 2.7 Emission standard of air pollutants for coal--burning oil- burning gas-fired boilers Discharge standard and standard code Standard for period Emission Pollutant factor II in GB13271-2001 parameter Emission Dust Unit Emission limitation mg/Nm3 200 mg/Nm3 900 concentration Emission SO2 concentration Table 2.8 Emission standard of air pollutants for industrial kiln and furnace Discharge standard and standard code Pollutant Emission factor parameter Dust Emission Level II in GB9078-1996 SO2 concentration Emission concentration Unit Emission limitation mg/Nm3 200 mg/Nm3 850 Table 2.9 Emission Standard for Odor Pollutants Discharge standard and standard code Table 1 (level II) in GB14554-93 Pollutant Emission factor parameter H2S Emission concentration 14 Unit mg/Nm3 Limitation at plant boundary 0.1 3)Noise The boundary noise implements requirements for level II in “Emission standard for industrial enterprises noise at boundary” (GB12348-2008). Refer to table 2.10. Table 2.10 Standard for industrial enterprises noise at boundary Standard and level implemented Level II inGB12348-2008 Standard value dB(A) Day Night 60 50 15 Application conditons / 3. Environmental protection management plan 3.1 Environmental management department and its responsibilities For the purpose of supporting the effective and timely implementation of environmental relief measure, EMP specially describe the arrangement of departments in accordance with the setting and responsibilities of environmental protection departments in environmental impact evaluation report. Refer to table 3.1. Table 3.1 list of setting and responsibilities of environmental protection departments Action Department responsible Monitoring data collection Construction Construction enterprise 1) period and Jinfu 2) 1) 2) 3) Operation period Jinfu 4) 5) 6) Department responsibilities collecting dust data collection noise data water quality at outlet of waste water station water quality at outlet of pulp making workshop smoke outlet of boiler smoke outlet of soda furnace odorous gas at the boundary monitoring water quality in wells for underground water at white sludge yard Data analysis Construction period Local monitoring Based on monitored data, analyze environmental quality situation during station construction period and understand major environmental problems Local monitoring Based on monitored data, analyze environmental quality situation during Operation period station operation period and understand major environmental problems Preparation of environmental monitoring report Construction Local monitoring Based on monitored data, prepare environmental monitoring report period station Local monitoring Based on monitored data, prepare environmental monitoring report Operation period station Acceptance/ frequency of environmental monitoring report Construction Construction enterprise Conduct irregular monitoring according to construction progress. period and Jinfu Construction enterprise accept one environmental monitoring report three month and responsible for sorting out and maintaining monitored Operation period Jinfu data and report to local environmental protection department when find problems and solve them. Environmental management 1) 2) Construction period Construction enterprise 3) 4) 1) Operation period Jinfu Designate one or two full-time or part-time staffs responsible for environmental protection and management during construction and production. Check the progress, quality, operation and test of environmental protection facilities and solve the problems during operation Calculate the utility of environmental protection fund during construction Accept the supervision of environmental protection administration department and environment monitoring department, report the implementation of environmental protection articles in contract. Set up an environmental management department as safety and environmental protection agency to responsible for implement environmental protection and management work in operation period. Designate five 16 2) 3) 4) 5) 6) 7) 8) 9) people to conduct environmental protection. Under the leadership of GM, department management shall be responsible for daily work of environmental protection management and clean production. Each workshop shall have two part-time environmental protection management staff responsible for maintenance of environmental protection facilities and contacting with safety and environmental protection agency. There are two staffs committed to professional health management. Implement national and local environmental protection laws, regulations and policies as well as the requirements of environmental protection authorities at all levels. Implement environmental protection measures, and propose environmental management methods and systems during operation period. Implement environmental monitoring during operation period and conduct statistic analysis as well as data management Monitor environmental protection measures and solve the environmental protection problems during operation period. Report regularly to environmental protection authorities. Conduct environmental protection acceptance work upon finish of construction. Be responsible for professional health protection and management of all staffs. Be responsible for proposing, construction and maintaining of risk prevention and implementing emergency response plan during accidents. 3.2 Environmental management plan and mitigation measurement Environmental protection measures and emergency response plan during operating period refers to Table 3.2. 17 Table 3.2 Environmental protection measures and emergency response plan Potential environmental problems Implementation period Mitigation measures and emergency response plan Budget (RMB10,000) Executing unit Supervision unit Monitoring indicators & parameters Frequency Construction period Dust -open storage ground and bare site being covered with geotextile; -dust throwing being taken into account during construction and spraying water to control over dust and regularly cleaning; -regular monitoring. Construction 1.5 Construction unit Construction noise -use low noisy equipment; -properly arrange construction time and avoid construction in night time. Construction 0.5 Construction unit Construction waste water -waste water collection pool being furnished. Waste water will be sent to waste water station for treatment and discharged together with production waste water after meeting criteria; -regular monitoring. Construction 18 0.5 Construction unit Jinfu Company, construction observation unit, Environmental Protection Bureau of Shawan, and Environmental Monitoring Station of Shawan Jinfu Company, construction observation unit, Environmental Protection Bureau of Shawan Jinfu Company, construction observation unit, Environmental Protection Bureau of Shawan TSP Every months 2 LeqdB(A) Once month a On-line monitoring COD、NH3-N、system in SS waste water station being used Construction waste -report to local construction bureau on disposal of construction waste residue. Small amount of waste spoil and construction rubble being sent to assigned disposal site in accordance with requirements issued by municipal administration and planning agency; -remaining sandstone, construction materials, steel, packing materials etc shall be managed and recycled by reponsibel person and storage ground being cleansed immediately without any residues. Construction 1.0 Construction unit household garbage -household garbage produced on construction site shall be collected with collection container and sent out to disposal site together with household garbage produced within the plant. Construction 0.5 Construction unit Dismantle facilities for technological renovation -clear underground pipeline and hiding facilities and rejected materials etc; -obsolete liquefied chlorine steel cylinders shall be recycled by qualified unit in accordance with relevant requirements; Construction -obsolete steam ball and other pulping equipment shall not be sold out to other pulping enterprises; - preclude environmental pollution caused by dismantling obsolete facilities. 2.0 Jinfu Company Social environment -a billboard shall be setup on the construction site that describes engineering content and construction time as well as narration for begging public acceptance and understanding of inconvenience caused by construction. Contact info and complaint hotline etc shall be provided; -construction management and training on environmental projection shall be enhanced. 0.5 Construction unit, Jinfu Company Construction 19 Jinfu Company, construction observation unit, Environmental Protection Bureau of Shawan, and Environmental Monitoring Station of Shawan Environmental Protection Bureau of Shawan Construction observation unit, Environmental Protection Bureau of Shawan, and Environmental Monitoring Station of Shawan Construction observation unit, Environmental Protection Bureau of Shawan, and Construction waste Daily monitoring household garbage Daily monitoring Liquefied chlorine cylinders, underground Timely pipeline, steam monitoring ball and other pulping facilities / Daily monitoring Soil erosion -properly arrange construction time. Avoid construction in raining day and shorten stacking time of earth and stone; -temporary stacking place shall be covered with geotextile; -original land service functions shall be restored right after finish Construction of the construction; -training on ecological and environmental protection shall be carried out for construction staff. Environmental Monitoring Station of Shawan Construction observation unit, Environmental Protection Bureau of Shawan, and Environmental Monitoring Station of Shawan air pollutants 0.5 Construction unit, Jinfu Company 25 Jinfu Company, Safety and environmental Protection Department Environmental Protection Bureau of Shawan, and Environmental Monitoring Station of Shawan SO2、NOx PM10 Every 3 months 20 Jinfu Company, Safety and environmental Protection Department Environmental Protection Bureau of Shawan, and Environmental Monitoring Station of Shawan SO2、NOx PM10 Every 3 months Soil erosion Daily monitoring Operating period -circulating fluidized bed coal-fired boiler and low nitrogen combustion technology shall be adopted; -low sulfur coal less than 0.5% shall be used; - the limestone desulfurization inside the furnace shall be Smoke from boiler adopted; Operating -the electrostatic precipitation of 4-electric field shall be adopted. Smoke will be emitted through 80m chimney after dust cleansing. - the electrostatic precipitation of 4-electric field shall be Smoke from caustic soda furnace adopted; -tail gas after cleansing and boiler smoke being emitted through Operating the same chimney. 20 -gas skirt being setup to collect waste gas exhausted from the High thick stench from stewing process; -photo-oxidation waste gas purifier being adopted to dispose high Operating 15 Operating 10 Operating / thick stench; -gas being emitted through 30m chimney after disposal. -waste gas skirts being setup at the waste gas generation points; Low thick stench from stewing and waste gas from washing, screening and bleaching -water spray tower being used to cleanse collected waste gas; -gas being emitted through 30m chimney after disposal; -waste water from water spray tower being regularly sent to stripping tower in caustic soda recycle workshop for treatment together with contaminated cool water. Tail gas from stripping tower being sent to caustic soda furnace for incineration. Tail gas from ClO2 production -the tail gas goes through cooling tank of steam ejection pump where the gas is absorbed by water and then emitted from 30m chimney. Environmental Protection Bureau of Shawan, and Environmental Monitoring Station of Shawan Environmental Jinfu Protection Company, Bureau of Safety and Shawan, and environmental Environmental Protection Monitoring Department Station of Shawan Environmental Jinfu Protection Company, Bureau of Safety and Shawan, and environmental Environmental Protection Monitoring Department Station of Shawan Jinfu Company, Safety and environmental Protection Department -exhausted gas collection facility being setup to collect most stench gas produced in pulping and then emitted in well organized form after meeting criteria; Non-organized exhausted gas -stripping tower to treat heavy contaminated cool water from caustic soda recycle workshop shall be furnished. Vaporized gas Operating being sent to caustic soda furnace for incineration; -coal yard and ash residue stack yard shall be spray water to avoid dust blowing. Ash residue shall be timely removed out 21 20 Jinfu Company, Safety and environmental Protection Department Environmental Protection Bureau of Shawan, and Environmental Monitoring Station of Shawan Thickness of stench Every months 6 Thickness of stench Every months 6 Methanol Every months 6 Thickness of stench Every months 6 from the yards; -health protection distance shall be setup that keep 100m away from the center of stewing, black liquid concentration facility and chemicals workshop; -100m health protection distance shall be setup from the center of aero-tank and sludge concentration and filter-pressing workshop in waste water treatment station; -green isolation space around the plant boundary shall be setup where grass, bush and arbor trees shall be planted as a three-dimension protection forest. Clear space within the plant shall be planted with vegetation and trees as many as possible so as to mitigate stench impact to surrounding environment; -Regularly monitoring. -black liquid from stewing being sent to caustic soda recycle Jinfu Company, Safety and environmental Protection Department facility and concentrated with vaporization, then sent for incineration. No emission; -process water from ClO2 is sent to ClO2 liquid and by-product of saturated Glauber’s salt liquid. No discharge; -mid-stage waste water, preparation waste water, contaminated Waste water pollutants cool water from black liquor evaporation concentration etc will Operating Jinfu Company pH, SS, CODCr, ammonia nitrogen, total P, total N, sulfide, volatile phenol Every 3 months Operating be sent to waste water station for disposal, where waste water is treated with 3 steps of “ABR + contact oxidation + shallow Working with qualified and capable monitoring unity to do Dioxin, AOX sampling and monitoring depth processing/steam float” and discharged into Daduhe River after meeting the requirements in Table 2 of the “Standard of Discharged Water Pollutants for Pulp and Paper Industry (GB3544-2008)”; -regularly monitoring. 22 / White sludge Sent to white sludge disposal site Operating 150 Disposal of solid waste Sludge from Sent to white sludge disposal site for separate disposal wastewater station Furnace ash residue Sold to cement plant Operating Operating / -oozing liquid from white sludge yard being collected and completely spray back. No discharge; White sludge yard Operating -collecting basin in white sludge yard being treated with period and after service lifetime seepage prevention; -observation well being setup for regular monitoring. 23 Environmental Protection Bureau of Shawan, and / Environmental Monitoring Station of Shawan Environmental Jinfu Protection Company, Bureau of Safety and Shawan, and / environmental Environmental Protection Monitoring Department Station of Shawan Changing trend of dioxin etc in the sludge shall and monitored by qualified and capable unit. Environmental Jinfu Protection Company, Bureau of Safety and Shawan, and / environmental Environmental Protection Monitoring Department Station of Shawan Environmental Jinfu Protection Jinfu Company, Company, Bureau of Safety and Safety and Shawan, and environmental environmental Environmental Protection Protection Monitoring Department Department Station of Shawan Jinfu Company, Safety and environmental Protection Department 40 Daily monitoring Daily monitoring be analyzed Daily monitoring Every months 6 -allowance volume of the regulating reservoir in waste water Jinfu Company, Safety and environmental Protection Department Environmental Protection Jinfu Company, Bureau of Safety and Shawan, and environmental / Environmental Protection Monitoring Department Station of Shawan Jinfu Company People’s Government of Fulu Township, Villagers’ / Committee of Shawan Village, Fulu Township station will be used as accidental water collection pool; -leaking prevention treatment shall be completely done at all Environmental risks possible facilities such as water pool, pulp tower, waste water Operating station, water tank, pipeline etc. Special treatment shall be done period 30 at bending points, socket connecting points and butt joints etc. At the same time hiding engineering shall be noted down for archive. -enhance enterprise non-organized emission control measurement so as to secure standard being met within the plant; -well communication channel shall be maintained with surrounding residents and regularly solicit comments and respond Social environment to them in timely manner; -actively communicate with villagers’ committee of Shawan Operating / Village, Fulu Township and maintain sound and faithful cooperation relationship with the village on enterprise Daily contact development, environmental protection, employment, resource utilization, village enterprise development etc. -the company sets up occupational health control and management section. 3 professional staff being assigned as responsible persons. Concurrent posts being assigned in each Occupational health environment workshop and team; Operating -comprehensive occupational health management regulation and emergency response plan shall be developed. Occupational health control and management details being setup in Operation 24 50 Occupational health control and management section of Jinfu Company Health Bureau of Shawan Dust, noise, high temperature, caustic soda, sulfuric acid, H2O2, hydrogen sulfide etc Every months 6 Specification/Manual. Personal protective equipment and user manual being provided to every worker; -entrust qualified occupational disease prevention and control agency to carry out identification and evaluation of operating places and occupational-disease-inductive factors and technical measurement being setup to control over hazards; -adopt relevant occupational health technology and prevention measurement, and meet relevant requirements stipulated in “Health Standard for Process Industry Design (GBE 1-2002)”; -health examination shall be implemented for all 510 workers annually. All 62 workers working at 15 points existing occupational health hazards shall be specially examined for occupational health (no suspected case infected occupational disease was found since establishment of the plant); -environment management status and capacity building plan being developed; -construction project will be finished by 2011 and pre-evaluation of occupational disease hazards and effectiveness evaluation of occupational disease hazards being implemented soon afterwards; -regularly carry out “occupational health management education and training plan” to enhance awareness of occupational disease prevention as well as correctly use personal protective equipment and improve occupational health management ability of management team; Regularly monitoring. 25 3.3 Recommendation for environmental mitigation measurement -actively seeking integral use methods of white sludge so as to mitigate stack volume of newly produced white sludge and remove existing white sludge stack. 26 4. Environmental monitoring plan 4.1 Purpose of monitoring The environmental monitoring includes two stages: monitoring during construction period and monitoring during operation period with the purpose of full and timely understanding the pollution trends of proposed project, understanding the impact degree and scope of project on local environmental quality, reporting feedbacks to environmental protection authorities, thus to provide scientific basis for environmental management of project. 4.2 Monitoring implementation Based on the environmental impact prediction results, sensitive points with potential serious pollution are selected as monitoring point. And based on the pollution situation during construction period and operation period, surface water quality, air quality and sound quality are selected as monitoring contents. The monitoring factors shall be determined based on the specific pollutants in project analysis. The monitoring method shall apply monitoring and analysis method for related project in “Technical specifications of environmental monitoring” issued by Ministry of Environmental Protection. Evaluation standard shall implement national standard in environmental evaluation. Monitoring authority shall be local environmental monitoring station. The responsible agency during construction period is the enterprise signed construction contract with Jinfu and the responsible agency during operation period is Jinfu. The supervision authority is Shawan District environmental protection bureau. 4.2.1 Environmental monitoring plan Refer to table 4 for monitoring plan during construction period and operation period. 4.2.2 Monitoring expense Refer to table 4 for monitoring expense during construction period and operation period. Table 4 list of monitoring plan during construction period and operation Monitoring period Environmental factor Monitoring point Two points as east of Construction dust plant boundary construction Construction waste / water period(1 year) One point at each side of Construction noise plant boundary Monitoring item Monitoring frequency Estimated expense Once two months 3000 / / Once two months 2000 TSP / LeqdB(A) Subtotal Operation period Waste water 5000 CODCr, NH3-N, Outlet of waste water SS, Volatile phenol station 27 Once three months 10000 AOX, dioxin 100 m downstream from ODCr, NH3-N, Outlet of waste water Volatile phenol station Color degree, Well of farmer total hardness, Underground water sulphate, ammonia Monitoring well of white nitrogen, CODMn sludge slag yard Surface water Waste gas Air noise Exhaust-funnel of boiler SO2、NOx、PM10 and soda furnace One point at upstream and three point at H2S、NH3 downstream of plant boundary LeqdB(A) One point at each side of plant boundary Subtotal Once a year when the provincial monitoring station has the ability; must be monitor at acceptance. 30000 Once six months 15000 Once three months 15000 Once three months 15000 Once three months 40000 Once six months 10000 Once three months 2000 137000 Total 142000 1) Consciously accept the annual routine testing, and monitoring indicators and frequency, sampling time and other factors should be on request, additionally, the enterprise should pay fee according to the national pollution monitoring and technical regulations. 2) Consciously maintain the normal operation of online monitoring equipments. Monitor the discharge situation according to the regulations of relevant laws and “environmental monitoring and management” and save the original monitoring data. The result of automatic monitoring should link to environmental protection competent department, and the enterprise should provide equipment security management. 3) consciously accept the sample detecting and total amount accounting testing, and help with the sampling and sample delivery. 4) Consciously collect the record of annual environmental monitoring and management. Provide monitoring data to administration department and World Bank according to the commitment in environmental management plan. 4.3 Monitoring Capacity Building (1)Jinfu Paper Mill has a dedicated environmental analysis lab that is staffed with 8 staff, among whom 3 are certified professional. Daily Analyzed parameters include CODcr, SS, pH,Chroma, and temperature. The lab is directly managed by the mill’s general manager and budgeted into the mill’s operational costs. (2) Online wastewater monitoring include wastewater flow rate, pH, and CODcr. 28 A new online monitoring equipment for NH3-N was just installed in 2011. Currently, the mill is planning to building NH3-N sampling and analysis capacity in the lab. Flue gas online monitoring equipment will be installed in 2012-2012 once the currently ongoing boilers renovation project is finished. Monitored parameters include flue gas temperature, flow rate, PM, SO2 and NOx. (3) The local environmental monitoring station shares online monitoring data with the mill. The local environmental monitoring stations conduct quarterly monitoring on wastewater, air emission. In addition, it conducts comparison monitoring test of the online equipment quarterly. At its discretionary, the monitoring station conducts grab monitoring to the mill and provide guidance. (4) During the 12th-5 year period (2011-2015), the mill will follow the requirement and planning of national and local environmental authorities to install other online monitoring system. (5)Monitoring validation for demonstrative project must be done independently; enterprises should fully co-operate with the monitoring, and provide relevant support. When dioxin base line, workshop section control, performance testing are being carried out, enterprise should provide necessary support, afford expense for synchronous monitoring extra but necessary indexes, and connect with the synchronous monitoring organization. The expense of independent monitoring of demonstrative project should be calculated separately. 5. Staff training 5.1 Training to new full-time and part-time environmental protection staffs during construction period Construction enterprise shall entrust qualified agency to provide training to new full-time and part-time environmental protection staffs during construction period. Staffs taking part in this training include technical responsible people and full-time management from construction and supervision enterprise. The training contents include national and Sichuan Provincial regulations, documents and relevant requirement concerning environmental protection and soil and water conservation in project management, environmental protection measure and requirements during construction period proposed by Jinfu during project design, and environmental protection guidance during construction period of project. The teachers may be invited from environmental protection bureau, or people responsible for environmental protection design and experts from environmental evaluation agency as well as supervision agency. 5.2 Training to new full-time and part-time environmental protection staffs during operation period Environmental protection authority is responsible for organization and implementation of training to new full-time and part-time environmental protection staffs during operation period. The teachers can be environmental protection experts from universities, research institutes and supervision agency. Refer to table 5.2 for short period training class. 29 Table 5.2 list of trainees and expense during construction and operation period Phase Construction period Operation period Number of trainee Trainee Responsible people from construction enterprise, environmental protection and special people from Jinfu 4 Supervision engineer 2 Content Laws regulations, , environmental protection measures and requirements during construction period, and environmental protection guidance Expense (10 thousand RMB) time 3-7 days before construction starts 1 0.75 Laws regulations, , environmental protection measures Environmental 1 and requirements, management staffs environmental protection guidance during operation period Laws regulations, , environmental protection measures and requirements, Environmental work 2 regular maintenance of staffs environmental protection facilities, collection and analysis of monitoring data Risk impact, risk Emergency response prevention measures 2 staff and emergency response plan Organization ,summary, communication, All production General Training for informal discussion and management staff report in the scope of staff whole plant, workshop and team 0.25 7-14 day before operation 0.5 0.5 Period or temporary Total 2 5 6. Estimated expenses for environmental management plan After estimation, the environmental management plan of this project shall be 232 thousand RMB. Table 6-1 list of expense for environmental management plan (10 thousand RMB) Environmental monitoring expense Construction Operation period period 0.5 13.7 Professional health management expense 4.5 30 Safety management expense Training expense Total EMP implementation expense 1.5 3.0 25.2 31 7. Information Exchange Environmental management requires not only to exchange necessary information between different departments and position in enterprise, but to report relevant information to outside (related parties and public). Internal information exchange can be conducted as meetings and internal news, etc. But there must be one official meeting and all exchanged information must he recorded and saved. External information exchange can be conducted once half a year or a year. The information exchange with cooperation agency shall form summary and be saved. 32 8. Record For the purpose of effective operation of environmental management system, enterprise must set up a complete record system and maintain the record of the following aspects: 1) Requirements of laws, regulations and relevant standards; 2) License documents; 3) Environmental factors and relevant environmental impact and environmental relief measures; 4) Training 5) Project construction progress; 6) Monitoring data; 7) Information about related parties; 8) Examination and approval; 9) Review. In addition, above record must be controlled necessarily, including label, collection, catalogue, saving, storage, management, maintenance, search, saving period and disposal of record. 33 9. Report Construction enterprise, monitoring agency and Jinfu shall record and report to related authorities regarding project progress, implementation of EMP, and environmental quality monitoring results. Report includes the following three parts: 1) Monitoring agency and Construction enterprise make detailed record on the implementation of EMP and report timely to project office; 2) Jinfu project office prepare the EMP progress necessary for project progress report (month report, quarterly report and annual report), such as the implementation progress and effectiveness of EMP; 3) The EMP implementation report shall report to World Bank once half a year. The EMP implementation report may include the following: 1) Implementation of training plan; 2) Project progress, such as technology upgrading construction; 3) Carrying out of environmental protection measures, implementation of environmental monitoring plan as well as monitoring data analysis and evaluation 4) In case of public complaint, the content of complaint, solving method and public satisfaction shall be recorded. 5) EMP implementation plan for next year. 34