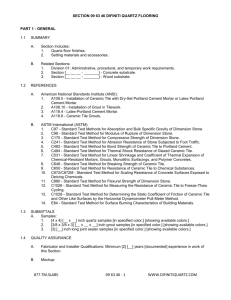

Specifications for my material

advertisement

Interior Wall Facings Specifications This guide specification has been prepared by Cosentino USA to assist design professionals in the preparation of a specification section covering Silestone engineered wall facings, including fireplace surrounds. Additional sections are available for other uses of Silestone including: Section 06417 – Engineered Stone Countertops Section 09635 – Engineered Stone Flooring This specification may be used as the basis for developing either a project specification or an office master specification. Since it has been prepared according to the principles established in the Manual of Practice published by The Construction Specifications Institute (CSI) including the use of 1995 Master Format section number and title, it may be used in conjunction with most commercially available master specifications systems with minor editing. The following should be noted in using this guide specification: Editing notes to assist users are included within bordered boxes. Delete these notes prior to final printing. Optional text requiring a selection by the user is enclosed within brackets, e.g.: “Section [01330] [ _____ ].” Optional text requiring a selection by the user is enclosed within brackets, e.g.: “Section [01330] [ ____ ].” Items requiring user input are enclosed within brackets, e.g.: “Section [ ___-___ ].” Optional paragraphs are separated by an “OR” statement, e.g.: **** OR **** Metric equivalents to inch-pound units follow the inch-pound units and are contained within parenthesis. Metric measurements are rationalized units based on the SI system or measurement. Delete either the inch-pound or metric units of measure depending on project requirements; do not include both units in a project specification, as conflicting requirements could result. This guide specification is available in both hard copy and a variety of electronic formats to suit most popular word processing programs and operating platforms. Please contact Cosentino USA at (800) 291-1311 or (281) 494-7277 for additional copies or for information on available electronic formats. PART 1 – GENERAL 1.1 SUMMARY A. Section Includes: Typical Home 3-28-2011 1. Engineered stone interior wall finishes. 2. [Engineered stone fireplace surrounds.] 3. Setting materials and accessories. Edit the following paragraph to suit project requirements: list only those sections specifically applicable to the work of the section. B. Related Sections: 1. Section [04800 - Masonry Assemblies] [_____-_____]: Masonry substrate. 2. Section [09210 - Gypsum Plaster] [_____-_____]: Plaster substrate. 3. Section [09260 - Gypsum Board Assemblies] [_____-_____]: Gypsum board substrate. 4. Section [_____-______]: Cementitious backing board substrate. 5. Section [07900] - Joint Sealers. 1.2 REFERENCES Edit the following paragraphs to suit project requirements: list only those references used elsewhere in the section. A. American National Standards Institute (ANSI): 1. A108.1 - Glazed Wall Tile, Ceramic Mosaic Tile, Quarry Tile and Paver Tile Installed with Portland Cement Mortar. 2. A108.5 - Ceramic Tile Installed with Dry-Set Portland Cement Mortar or Latex-Portland Cement Mortar. 3. A108.10 - Installation of Grout in Tilework. 4. A118.4 - Latex-Portland Cement Mortar. 5. A118.6 - Ceramic Tile Grouts. B. American Society of Testing and Materials (ASTM): 1. C 97 - Test Method for Absorption and Bulk Specific Gravity of Dimension Stone. 2. C 99 - Test Method for Modulus of Rupture of Dimension Stone. 3. C 241 - Test Method for Abrasion Resistance of Stone Subjected to Foot Traffic5. 4. C 373 - Test Method for Water Absorption, Bulk Density, Apparent Porosity, and Apparent Specific Gravity of Fined Whiteware Products. 5. C 482 - Test Method for Bond Strength of Ceramic Tile to Portland Cement. 6. C 484 - Test Method for Thermal Shock Resistance of Glazed Ceramic Tile. 7. C 531 - Test Method for Linear Shrinkage and Coefficient of Thermal Expansion of Chemical-Resistant Mortars, Grouts, and Monolithic Surfacings. 8. C 648 - Test Method for Breaking Strength of Ceramic Tile. 9. C 650 - Test Method for Resistance of Ceramic Tile to Chemical Substances. 10. C 672 - Test Method for Sealing Resistance of Concrete Surfaces Exposed to Deicing Chemicals. 11. C 880 - Test Method for Flexural Strength of Dimensional Stone. 12. C 1026 - Test Method for Measuring Frost Resistance of Ceramic Tile to Freeze-Thaw Cycling. 13. E 84 - Test Method for Surface 1.3 SUBMITTALS Typical Home 3-28-2011 Edit the following paragraph to indicate the correct Division 1 section. A. Submit under provisions of Section [01330] [ ____ ]: 1. Shop Drawings: Indicate flooring layout, dimensions, patterns, and control joint locations. 2. Product Data: Provide information on flooring and setting materials. 3. Samples: [12 x 12] [ ___ x ___ ] inch ([300 x 300] [ ___ x ___ ] mm) facing samples showing [each] color and finish. Edit the following paragraph to indicate the correct Division 1 section. B. Submit under provisions of Section [01780] [ ____ ]: 1. Maintenance Data; Indicate cleaning instructions, scratch removal procedures, and materials harmful to facing. 1.4 DELIVERY, STORAGE AND HANDLING Edit the following paragraph to indicate the correct Division 1 section. A. Deliver, store and handle products under provisions of Section [01600] [ ____ ]. B. Deliver facing in protective coverings. Do not remove from coverings until needed for installation. C. Protect mortar and grout containers from freezing and overheating. 1.5 PROJECT CONDITIONS A. Maintain ambient temperature between 50 and 95 degrees F (10 and 35 degrees C) for 48 hours before, during and for minimum 7 days after installation. 1.6 MAINTENANCE Include the following paragraph if extra materials for the Owner’s future maintenance needs are desired. Edit to suit project requirements; indicate the correct Division 1 section. A. Extra Stock: 1. Provide under provisions of Section [01780] [ ____ ]. 2. Quantity: [2] [ _ ] percent of each color and finish. PART 2 - PRODUCTS 2.1 MANUFACTURERS A. Source: Silestone by Cosentino SA, Apdo No. 1, Macael 04867, Almeria, Spain. Edit the following paragraph to indicate whether substitutes will be permitted: indicate the correct Division I section. B. Substitutions: [Not permitted.] [Under provision of Section [01630] [ ___ ].] Typical Home 3-28-2011 2.2 FACING MATERIALS A. Engineered Stone Facing: 1. Composition: Quartz aggregate, resin, and color pigments formed into flat slabs. 2. Physical characteristics: a. Water absorption: Maximum 0.04 percent, tested per ASTM C 97. b. Bond strength: Average of 211 PSI (1.4 MPa), tested per ASTM C 482. c. Modulus of rupture: Average of 6200 PSI (51.1 MPa), tested per ASTM C 99. d. Flexural strength: 5620 PSI (50.3 MPa), tested per ASTM C 880. e. Abrasion index: Minimum 62, tested per ASTM C 241. f. Thermal shock: Pass 5 cycles, tested per ASTM C 484. g. Thermal expansion: 1.747 x 10 -5, tested per ASTM C 531. h. Freeze thaw: Class MR3+, tested per ASTM 1026. i. Deicing: Pass ASTM C 672. j. Flame spread: Class 1 (FS-25 or less), tested per ASTM E84. k. Mohs hardness: 6 to 6.5. l. Stain resistance: Stains completely removed, tested per ASTM C 650, excluding hydroxide. Include the following paragraph for tiles: edit to suit project requirements. Standard sizes are listed: contact Cosentino USA for special sizes. 3. Size: [12 x 12 inches (300 x 300 mm) x 3/8 inch (10 mm) thick] [18 x 18 inches (450 x 450 mm) x 3/8 inch (10 mm) thick] [24 x 24 inches (600 x 600 mm) x 3/8 inch (10 mm) thick] [ ____x____ inches ( ____x____ mm) x 3/8 inch (10 mm) thick]. *****OR***** Include the following paragraph for slabs; edit to suit project requirements. 3/8” thickness is recommended for all panel sizes. 4. Thickness: [3/8] [3/4] inch ([10] [19] mm). 5. Color: [ ___ ] [To be selected from manufacturer’s standards] [Custom color to be selected]. 6. Surface finish: [Polished]. If resistance to chemicals is a project requirement, statements can be added here. Refer to Silestone technical binder for information on chemical resistance. 2.3 SETTING MATERIALS Include the following paragraph for adhesive. A. Adhesive: Liquid Nails or other approved by panel manufacturer. *****OR***** Include the following two paragraphs for thin set mortar. B. Latex-Portland Cement Mortar: ANSI A118.4. C. Latex Admixture: 100 percent latex type. *****OR***** Typical Home 3-28-2011 Include the following four paragraphs for thickset mortar. D. Portland Cement: ASTM C 150, Type 1, [gray] [white] color. E. Sand: ASTM C 144, clean, free or organic matter, passing a No. 16 sieve. F. Lime: ASTM C 207, Type S, hydrated. G. Latex Admixture: 100 percent latex type. Do not use water. H. Grout: 1. ANSI A118.6, cementitious type with latex additive. 2. Color: [ ___ ] [To be selected from manufacturer’s standards]. 2.4 ACCESSORIES Coordinate the following paragraph with the joint sealants section. Silicone sanitary sealants are recommended where resistance to mildew is required. A. Joint Sealants: Single component [polyurethane] [silicone sanitary] sealant and backing materials; specified in Section [07900] [ ____ ]. Include the following paragraph only for a reinforce thick-set mortar bed. B. Reinforcing: 2 x 2 inches (50 x 50 mm), 16/16 gage (1.6/1.6 mm) welded wire mesh, hot dip galvanized. 2.5 MIXES A. Mix mortar and grout with latex admixture in accordance with manufacture’s instructions. Do not use water. PART 3 - EXECUTION 3.1 PREPARATION A. Clean surfaces to remove loose and foreign matter that could impair adhesion. B. Remove ridges and projections. Fill voids and depressions with patching compound compatible with setting materials. C. Allowable Substrate Tolerances: Include the following two paragraphs for organic adhesive and a thin-set mortar bed applications. 1. Maximum variation in substrate surface: 1/8 inch in 8 feet (3 mm/2400 mm). 2. Maximum height of abrupt irregularities: 1/32 inch (1.0 mm). **** OR **** Include the following paragraph for a thick-set mortar bed. 3. Maximum ¼ inch in 10 feet (6 mm/3 m) variation in subfloor surface. 3.2 INSTALLATION Typical Home 3-28-2011 Include the following paragraph for panels over 18 x 18 inches (450 x 450 mm) in size. A. Install facing with adhesive applied in accordance with manufacturer’s instructions. *****OR***** Include the following paragraph for panels 18 x 18 inches (450 x 450 mm) in size or less to be installed with a thin-set mortar bed application. B. Install facing in accordance with ANSI A108.5, thin set with latex portland cement mortar. *****OR***** Include the following paragraph for panels 18 x 18 inches (450 x 450 mm) in size or less to be installed with a thick-set mortar bed application, reinforced or plain; edit to suit project requirements. C. Install facing in accordance with ANSI A108.1, thick set with [reinforced] mortar bed. Include the following paragraph if a reference to the TCA Manual is desired: edit to suit project requirements. D. Install facing in accordance with TCA Method F-[ ___ ]. E. Minimize pieces less than one half size. Locate cuts to be inconspicuous. F. Lay facing to [ ___ ] [indicated] pattern. G. Place facing with uniform, minimum [1/6] [ ___ ] inch ([2] [ __ ] mm) wide joints. H. Fit facing around projections and at perimeter. Smooth and clean cut edges. Ensure that trim will completely cover cut edges. I. Sound facing after setting and before grouting. Replace hollow sounding units. J. Allow facing to set for a minimum of 48 hours before grouting. K. Grout tile joints in accordance with ANSI A108.10 without excess grout. Tool to [concave] [ ___ ] profile. L. Install control joints over joints in substrate. Fill with sealant as specified in Section [07900] [ ___ ]. 3.3 PROTECTION A. Protect completed work under provisions of Section [01760] [ ____ ] using nonstaining sheet coverings. END OF SECTION Typical Home 3-28-2011