File

advertisement

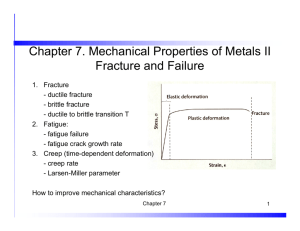

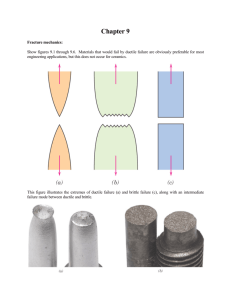

SRM UNIVERSITY, RAMAPURAM CAMPUS DEPARTMENT OF MECHANICAL ENGINEERING UNIT 2 FRACTURE BEHAVIOUR Part - A (Two marks) 1. Define fracture and list the types. Fracture It is the end result of plastic deformation process. Separation of a body under stress into two or more parts. Caused either by physical or chemical forces. Results in creation of new surfaces. Types of fracture 2. 3. 4. 5. Ductile fracture Brittle fracture Creep fracture Fatigue fracture Explain Shearing fracture. Occurs as a result of extensive slip on active slip plane. Promoted by shear stress. Single crystal of h.c.p metals may slip on successive basal planes until finally the crystal separates by shear. Differentiate Brittle fracture and ductile fracture. Ductile fracture S.No. Brittle fracture 1 Characterized by rapid rate of crack propagation with minimal energy absorption Characterized by appreciable plastic deformation prior to and during propagation of crack 2 Occurs by separation normal to tensile stress Preceded by localized deformation by necking 3 Observed in BCC and HCP metals Observed in FCC metals Define Ductile to Brittle transition temperature. When BCC metals subjected to impact loads, comparatively at low temperatures, a transition occurs from ductile fracture (requiring higher energy) to brittle fracture (requires low energy). It is called as Ductile to Brittle temperature. Depends on Rate of strain, crystal structure, grain size and stress distribution, etc. Define Stress intensity factor. It is defines as the local stresses near the crack that depends on the product of nominal stress and the square root of half of the flaw length. k = (c) If the value of k is same for two flaws of different geometry, stress filed around each flaw is identical. 1 SRM UNIVERSITY, RAMAPURAM CAMPUS DEPARTMENT OF MECHANICAL ENGINEERING 6. Define the term Fracture toughness. It is defined as a property that measures the resistance of a material to brittle fracture when a crack is present. kc = y (c) y – Dimensionless parameter depends on crack, specimen size, geometry and load y = 1 for thorough thickness of crack y = 0.6 for semicircular crack y = 0.8 for semi elliptical crack y = 1.12 for Edge crack y = 0.86 for Cone crack 7. Define creep strength. Property of material by virtue of which it deforms continuously under a steady load for prolonged time period. Viscous flow in metals involving applied stress, time and temperature. 8. List out the different mechanisms takes place in creep fracture. Dislocation glide Dislocation climb Creep due to grain boundaries / Coble creep ro-Hering creep 9. Differentiate dislocation glide and dislocation climb. S.No. Dislocation climb Dislocation glide 1 Takes place at low temperature and higher stress Takes place at high temperature and low stress 2 Rate of creep increased by thermal activation Rate of creep depends on rate of escape of dislocation past the obstacles 3 Transient creep takes place Viscous creep takes place 10. What is the use of Deformation mechanism map? It indicates the dominant deformation mechanism takes place for different Stress – Temperature combination. The boundary represents the combination of stress-temperature at which strain rate of two mechanisms is equal. Allows selection of two or three variables (stress, strain rate or temperature), for applications. 2 SRM UNIVERSITY, RAMAPURAM CAMPUS DEPARTMENT OF MECHANICAL ENGINEERING 11. Differentiate transient creep and viscous creep. S.No. Viscous creep Transient creep 1 Takes place at low temperature and higher stress Takes place at high temperature and low stress 2 Occurs when operated at stresses in plastic range Occurs when operated above flow temperature 3 Takes place highly in Crystalline materials Takes place highly in Amorphous materials 4 Low temperature creep High temperature creep 12. Define fatigue limit. It’s also called as Endurance limit A definite stress below which failure by fatigue does not takes place, no matter how many times the stress repeated or reversed. When series of stress is plotted against the number of cycles to failure at each stresses, it becomes perfectly horizontal at this limit. 13. What are the different types of Fatigue loading? Reversed load Alternating load Fluctuating load Repeated load Irregular load 14. What are the different mechanisms takes place during fatigue fracture? Crack initiation Slip-band crack growth Crack growth on planes of high tensile stress Ultimate ductile fracture 15. What are the variables affecting the fatigue life? Surface condition of material Temperature Range of stress / Mean stress Frequency of stress cycle Environment Metallurgical factor 16. State Cumulative damage theory. The theory states that each series of stress cycles account for a certain fraction of the total damage and when these fractions addup to unity, failure occurs. The fraction of total damage done by one series of cycles at a particular stress level is given by the ratio of number of cycles (n) actually endured at that level to the fatigue life (N) at that level. Cycle ratio, C = ni / Ni 3 SRM UNIVERSITY, RAMAPURAM CAMPUS DEPARTMENT OF MECHANICAL ENGINEERING 17. What is meant by Plastic blunting process? Occurs at stage-II crack propagation. As a result of repeated tensile and compressive load on the crack tip, the slip direction reverses at the crack tip. Due to plastic shear the crack grows and crack tip becomes sharp and blunt simultaneously. This phenomenon is called as Plastic Blunting. 18. Define Notch sensitivity. Reduction of nominal strength, static or impact, by the presence of stress concentration. Expressed as ratio of the notched to the un-notched strength. Makes a ductile material to undergo brittle fracture. 19. What are the sources of failure? Improper material selection Improper processing Inadequate design Misuse of components 20. Define Equi-cohesive temperature. When the temperature is increased the role of grain boundary is reversed from one of resisting deformation to one of aiding deformation. This temperature of inversion is called as Equi-cohesive temperature. It is the temperature at which strength of grains and grain boundaries are equal. 21. State Paris law. Paris – Erdogan law relates the stress intensity factor range to subcritical crack growth under fatigue stress regime. 𝑑𝑎 = 𝑐 𝑘 𝑚 𝑑𝑁 Where, a N k c&m – Crack length – Number of cycles – Stress intensity factor – kmax - kmin – Material constant Material Technology 1.Mr. D.K.Mohan Kumar.,(Course Coordinator) Dept.of.Mech.Engg.SRM University, Chennai. 2.Mr.Easwar., Dept.of.Mech.Engg.SRM University, Chennai 3..Mr.Akbhar Aasiq Husain.., Dept.of.Mech.Engg.SRM University, Chennai HOD/MECH 4 SRM UNIVERSITY, RAMAPURAM CAMPUS DEPARTMENT OF MECHANICAL ENGINEERING 5