View

advertisement

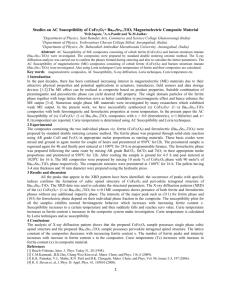

ME effect studies of ferrite-ferroelectric Magnetoelectric Composite R. A. Kunale1, R. H. Kadam1*, D. R. Mane2, G. B. Todkar3 1 2 Department of Physics, Shrikrishna College Gunjoti, Tq. Omerga, Dist. Osmanabad, India. Registrar of Dr. Babasaheb Ambedker Marathwada University Aurangabad,Aurangabad, India. 3 Dayananad Science College Latur, Dist. Latur, India. * Corresponding author’s e-mail:rkunale@yahoomail.com, Tel.: +91-8600656959 Abstract The magnetoelectric (ME) composites with composition (1-x) Ni0.5Cu0.3Mg0.2Fe2O4 + (x) BaTiO3 in which x = 0, 0.20, 0.40, 0.60,0.8 and 1 mol were prepared by conventional solid state reaction. The phase purity of ferrite and ferroelectric in composites is confirmed by xray diffraction studies. ME voltage coefficient was measured as function of applied dc magnetic field and variation in ME response has been explained in terms of the content of piezoelectric phase and the intensity of applied magnetic field. The magnetoelectric properties of these composites depend on the ferrite content, ferroelectric content and resistivity of constituent component of composites. The ME Voltage coefficient increases with increase in ferroelectric content in composites. The maximum ME voltage coefficient of 257mV/cm-Oe was observed for composite with x=0.8. Keywords:Magnetoelectric effect, Resistivity, Composites, X-ray diffaraction, ferrite, ferroelectric. Introduction Magnetoelectric composites prepared by combining together ferrite i.e. magnetic materials and ferroelectric i.e. electric materials, in which the mechanical coupling between ferrite and ferroelectric substances can produce magnetoelectric effect, have drawn significant attention in recent years. The materials which exhibit magnetoelectric effect are termed as magnetoelectric ceramics and they are considered to be promising candidates for sensors, processors, actuators and memory systems. These composites possess ME effect which is absent in their individual ferrite and ferroelectric phases [1]. ME effec couples two field effect in which 1)electric polarization on application of AC or DC magnetic field and 2) the magnetic polarization on application of AC or DC electric field[2,3]. The magnetoelectric effect is due to the mechanical coupling between piezomagnetic-ferrite and piezoelectric-ferroelectric phases [4]. The ME effect is a result of the product of inherent properties like magnetostriction and piezoelectric effect of the constituent phases present in the composite. Van Suchtelen [1] proposed the “product property” for ME composites. ME composites are prepared by sintering mixtures of piezoelectric and magnetostrictive materials. ME effect in these composites entails the combined deformation of the matrix of the piezoelectric and magnetostrictive components [4, 5].A primary deformation of the magnetostrictive phase causes polarization of the piezoelectric particles of composite; on the other hand, electric polarization of piezoelectric materials causes change in magnetization of the ferrite phase due to mechanical coupling of piezomagnetic (ferrite) and piezoelectric (ferroelectric) phases. In the last few decades, extensive work has been conducted in the era of magnetoelectricity. The composite of ferrite-ferroelectric phase can be synthesized by ceramic method [6-9] and wet chemical method [10]. From literature it is clear that the work on these magnetoelectric composites is limited to measurement of ME effect only. V.L. Mathe have studied the ME effect in CoFe2O4–BaTiO3. The value of magnetoelectric voltage coefficient observed was 140 μV/cm/Oe [11]. Gelyasin [12] have measured the ME coefficient with ac magnetic field for NiFe2O4– BaTiO3 composites. All researcher are trying to obtain maximum ME voltage coefficient by using different elements and their composition in ferrite and ferroelectric phase. Small amount of change in composition causes large change in ME effect. This effect would make the conversion between electric energy and magnetic energy possible. This provides Opportunities for potential applications of these as ME memories, wave-guides, transducers, radioelectronics, optoelectronics, microwave electronics and as transducers in instrumentation [13, 14]. The selection of ferrite and ferroelectric materials depends on the various factors like high magnetostriction coefficient and piezoelectric coefficient, high dielectric permeability and poling strength. As reported earlier the Ni containing ferrite were high resistive and magetostrictive. In the present work Ni0.5Cu0.3Mg0.2Fe2O4 is used as ferrite phase. The Ni ferrite shows better magnetic properties. The Ni ferrite is substituted with Mg and Cu. Ni2+ and Cu2+ are Jahn–Teller ions. The Ni–Cu ferrite have high mechanical coupling leading to high magnetostriction and high saturation magnetization. BaTiO3 (BTO) is selected as the ferroelectric phase. It was well known that BaTiO3 exhibits a better piezoelectric properties and a high dielectric constant. The two compounds can be successfully incorporated into a composite, it is expected that the composites might have interesting 0.00 0.20 0.40 0.60 0.80 1.00 Lattice constant for ferroelectric (Ao) a c c/a rati o 3.784 3.983 3.986 4.009 4.020 1.010 1.011 1.011 1.011 1.010 3.822 4.026 4.029 4.052 4.060 The values of lattice constant ‘a’ for ferrite phase, ‘a’ and ‘c’ for ferroelectric phase are given in Table1. The variation of lattice constant ‘a’ for ferrite phase and ‘a’ and ‘c’ for ferroelectric phase with composition ‘x’ is shown in Fig.2. It is clear from Fig. 2, that the values of lattice constant ‘a’ for ferrite phase decreases as the percentage of ferroelectric material in composite increases and the values of lattice constants ‘a’ and ‘c’ for ferroelectric phase increases as the percentage of ferrite material decreases in composite. 1800 x=0.80 # Ferrite phase * Ferroelectric Phase 1600 1400 1200 1000 *(220) 400 *(210) 600 *(211) 800 *(200) The crystal structures of composites and their constituent phases were determined by XRD technique using Philips X-ray diffractometer using Cu Kα radiation. The magnetoelectric (ME) effect measurements of the samples were carried out under induced electric polarization by an applied magnetic field and induced magnetization by an applied electric field. Electric and magnetic poling of the composites was made to increase the magnetostriction coefficient of the ferrite phase and the piezoelectric coefficient of the ferroelectric phase. The electric poling was carried out by heating the samples at about 30oC above the ferroelectric Curie temperature in an external electric field. The magnetic poling was carried out by applying DC magnetic field at room temperature and in the same setup the static ME voltage coefficient (dE/dH)H measured. The magnetic field applied normal to the flat and polished surfaces of the composite pellets with good electric contacts induces the electric voltage as a function of magnetic field and was measured with high impedance kiethley electrometer. Lattice Consta nt for ferrite (Ao) 8.316 8.281 8.260 8.255 8.250 - *(111) property Com posit in *(110) and Lattice parameters of Ferrite, Ferroelectric phases with their c/a ratios of (1-x) Ni0.5Cu0.3 Zn0.2 Fe2O4+(x) BaTiO3 for (x = 0.0-1.0) #(311) 2. Characterization measurement: Table: 1 #(220) The components of present composites are BaTiO3 as ferroelectric phase and Ni0.5Cu0.3Mg0.2Fe2O4 as a ferrite phase with general formula (1-x)Ni0.5Cu0.3Mg0.2Fe2O4+ (x) BaTiO3 in which x = 0, 0.20, 0.40, 0.60, 0.80,1 mol were prepared by conventional solid state reaction. The ferrite phase was prepared by NiO, CuO, MgO, and Fe2O3 in required molar proportions. These oxides were mixed and grind in agate mortar for couple of hours. The ferroelectric phase was prepared by using BaO and TiO2 as starting materials. These oxides are also mixed and grind in agate mortar. The ME composites were prepared by mixing 0.8,0.6,0.4 and 0.2 mol of ferrite phase with 0.2,0.4,0.6,and 0.8 mol of ferroelectric phase respectively. The required molar proportions were mixed and grind for 3 hour. The grind powder mixture was pressed into pellets using hydraulic press. The pelletized sample was final sintered in programmable furnace and slow cooled to room temperature to yield the final product. *(100) 1. Experimental: Fig.1 shows the XRD pattern of composites with x=0.80. The peaks are characteristics of both ferrite and ferroelectric phases. The intensity as well as number of ferroelectric peaks increases with increase in ferroelectric content in composites. It may be due to increase of molar percentage of ferroelectric. The Ni0.5Cu0.3Zn0.2Fe2O4 ferrite phase has cubic spinel structure. The ferroelectric phase has tetragonal pervoskite structure. The lattice parameters are shown in the following table 1. Intensity(arb.unit) electrical as well as magnetoelectric properties. Hence we have chosen Ni0.5Cu0.3Mg0.2Fe2O4 as a ferrite phase and BaTiO3 as a ferroelectric phase to form the composites. We report here magnetoelectric effect of these ME composites. 200 0 20 30 40 50 60 70 80 2Theta(Degree) 3. Result and Discussion: 3.1 Phase Determination Fig.1 XRD Patterns of (1-x)Ni0.5Cu0.3Mg0.2Fe2O4+ (x) BaTiO3 (x = 0.80) 8.4 3.3 Magnetoelectric (ME) Effect: 8.36 8.32 8.28 8.24 Lattice constant 'a' (Ferrite phase) Lattice constant 'a' and 'c' (Ferro. phase) Ferroelectric phase 'c' Ferroelectric Phase 'a' Ferrite phase 'a' 8.2 0 0.2 0.4 0.6 0.8 Composition 'x' 1 Fig. 2: Variation of lattice constant ‘a’ and ‘c’ for both ferrite and ferroelectric phases of the series (1-x) Ni0.5Cu0.3Mg0.2Fe2O4+(x)BaTiO3 3.2 Scanning Electron Microscopy: dE/dH (mV/Cm-Oe) Powder morphology was observed via scanning electron microscopy. Scanning electron microscope (SEM) is one of the most versatile instruments available for the examination and analysis of the micro structural characteristics of materials. The reason for using the SEM is the high resolution and appropriate magnification. The scanning electron micrographs of the all the samples of series under investigation are presented in Figs. 2. The scanning electron micrographs of samples show that the sample has an agglomerated large grain structure. Heating results in the well-faceted grains to form solid bodies. First the ME effect was observed a single crystal (Cr2O3). The ME effect is due to the local interaction between the ordered magnetic and ferroelectric sub-lattices. ME response depends on both magneto-mechanical resonance in ferrite phase and electro-mechanical resonance in ferroelectric phase. ME effect depends on the applied magnetic field, mole percentage of constituent phases and mechanical coupling between the two phases . ME coupling can be achieved by mediating stress in between the two phases. The variation in magnetoelectric conversion factor with applied DC magnetic field is shown in Fig.3. From Fig. 3 it is to be noted that there is increase in ME output [dE/dH]H with applied magnetic field, then reaches a maximum value and there after decreases. The constant value of [dE/dH]H indicates the saturation value of magnetostriction at the time of poling and it produces constant electric field in the ferroelectric phase. The ME effect depends on mol% of ferrite and ferroelectric phases. Initially ME coefficient increases slowly and after that increase in mole percentage of ferroelectric phase [dE/dH]H increases. The maximum value of ME voltage coefficient of 257 mV/come was observed for x=0.80 of composite and the lower values of ME output obtained at x=0.20. Due to low resistivity of ferrite phase, the transfer of the accumulated charges takes place between ferrite and ferroelectric phases at the time of poling [15]. The increase in ME output at x=0.80 is due to the uniform distribution of small grain sizes in the two phases. The strong compositional dependence that peaks at low ferrite content is a common feature for ferrite composites, because the conductivity percolation between ferrite grains tends to limit the effect of poling and to shorten the internal electrical field required for piezoelectricity. 300 x=0.2 x=0.4 x=0.6 x=0.8 250 200 150 100 50 0 0 1 2 3 Magnetic field (KOe) 4 Fig.3 Variation of magneto electric coefficient with magnetic field for (1-x)Ni0.5Cu0.3Mg0.2Fe2O4+ (x) BaTiO3 Fig 2: SEM images of (1-x) Ni0.5Cu0.3Mg0.2Fe2O4+ (x)BaTiO3 for x=0.0 Comparing the maximum value of dE/dH, 257 mV/cm-Oe for present composite, with the data in the literature, we find it is several orders higher than that of the magnetoelectric compounds and solid solutions [16, 17] and that of spinel-ferrite/BaTiO3 (16.2 mV/cm-Oe), spinel-ferrite/ PZT (30.2 mV/cm-Oe) composites [18, 19] and Ni-ferrite/PZT (up to 115 mV/cm/Oe) composites [20]. Conclusion: The ferrite-ferroelectric ME composites prepared successfully by standard ceramic method. The XRD pattern shows presence of both ferrite and ferroelectric phases. The intensity and number of ferroelectric peaks are observed to increases with increase in ferroelectric content in the composites. SEM image shows the grain formation. The ME voltage coefficient also increases with increase in ferroelectric content. The maximum value of the ME voltage coefficient is 257 mv/cm/Oe observed for composite with x=0.8 Refrences: [1] J. Van Suchetelene, Philps Res. Rep., Vol.27, 1972, pp. 28-37. [2] R. Grossinger, G.V. Doung, R.S. Turtelli, J. Magn. Magn. Mater., “The physics of magnetoelectric composites” Vol. 320, 14 , 2008, pp.1972–1977. [3] S.A. Lokare, R.S. Devan, B.K. Chougule, J. Alloys Compd. “Structural analysis and electrical properties of ME composites” Vol.454, 2008, pp. 471–475. [4] A.M.J.G. Van Run, D. R. Terrel and J. H. Scholing, J. Mater. Sci. “An in situ grown eutecticmagnetoelectric composite material”Vol. 9, 10, 1974, pp.1710-1714. [5] J.V. Boomgaard, R.A.J. Born, J. Mater. Sci. “A sintered magnetoelectric composite material BaTiO 3 Ni(Co, Mn) Fe 2O4”, Vol.13, 7, 1978, pp.1538-1548. [6] R.C. Kambale, Y.A. Park, K.Y. Rajpure, S.S. Suryavanshi and N. Hur, Journal of the Korean Physical Society “Studies on dielectric and magnetic properties of Co-Mn ferrite and BZT ferroelectric particulate ME composites” , Vol. 59, No. 5, 2011, pp. 1-6 [7] Jiang-Li Chen , Zhuo Xu, Shao-Bo Qu, Xiao-Yong Wei, Xiao-Hui Liu, “Ceramics International, Electromagnetic properties of ferroelectric-ferrite ceramic composites”, Vol. 34, 2008, pp. 803–807. [8] C.M. Kanamadi and B.K. Chougule, J. Electroceramics, “Studies on Electrical Properties and Magnetoelectric Effect of (x)Ni0.8Cu0.2Fe2O4+(1x)Ba0.8Pb0.2Ti0.8Zr0.2O3 Composites” Vol.15, 2, 2005, pp. 123-128. [9] K.K Patankar, V.L. Mathe, R.N. Patil, B.K. Chougule, Mater. Chem. And Phy. “Structural analysis, magnetic properties and magnetoelectric effect in piezomagnetic–piezoelectric composites”, Vol. 96, 5-6, 2006, pp. 197-200. [10]Rahul C. Kamble, K. M. Song, N. Hur. Current Applied Physics, “Structural, magnetic and magnetoelectric behavior of BaTiO3-CoMn0.2Fe1.8O4 particulate magnetoelectric composites”Vol.13, 2013, pp. 562- 566. [11] R.P. Mahajan, K.K. Patankar, M.B. Kothale, S.C. Chaudhary, V.L. Mathe , S. Patil, J. Of Physics, "Magnetoelectric effect in cobalt ferrite- Barium titanate composites and their electrical properties" Vol.58, No 5, 2002, pp. 1115-1124 [12] A.E Gelyasin, V.M Latetin and L.I Trofimovich, Sov. Phys. Tech. Phys., “Magnetic bias influence on resonance frequency composite ceramics ferritepiezoelectric”, Vol. 33, 1998, pp. 9-11 [13] S.V. Suryanaryana, Bull. Mater. Sci., “Magnetoelectric interaction phenomenon in materials” Vol.17, 7, 1994,pp. 1259-1270. [14] H. Schmid, Bull. Mater. Sci., “Magnetic ferroelectric materials” Vol.17, 7, 1994,pp. 1411-1414. [15] S.A. Lokare, R.S. Devan, D.R. Patil, B.K. Chougule, J. Mater Sci: Mater Electron, “Studies on electrical properties of (x) BaTiO3 + (1−x) Ni0.92Co0.03Mn00.05Fe2O4 ME composites” Vol.18,12, 2007,pp. 1211–1215. [16] I. Kornev, M. Bichurin, J.P. Rivera, S. Gentil, H. Schmid, A.G. M. Jansen, and P. Wyder, Phys. Rev., “Magnetoelectric properties of LiCoPO4 and LiNiPO4” Vol. B 62, no. 18, 2000, 12247-12253. [17] M. M. Kumar, A. Srinivas, G. S. Kumar, and S. V. Suryanarayana, J. Phys.: Condens. Matter, "Investigation of the magnetoelectric effect in BiFeO3– BaTiO3 solid solutions", Vol.11, 1999, pp. 8131-8139. [18] J. V. Boomgaard and R. A. J. Born, J. Mater. Sci. “A sintered magnetoelectric composite material BaTiO3-Ni(Co, Mn)Fe2O4” Vol. 13, 1978, pp. 15381548. [19] J. Y. Zhai, N. Cai, L. Liu, Y. H. Lin, and C. W. Nan, Mater. Sci. Eng., Vol.B 99, 2003, pp.326-329. [20] S. Mazumder and G. S. Battacharyya, Mater. Res. Bull.,“Magnetoelectric behavior in in situ grown piezoelectric and piezomagnetic composite-phase system”, Vol.38, 2, 2003, pp.303-310.