View

advertisement

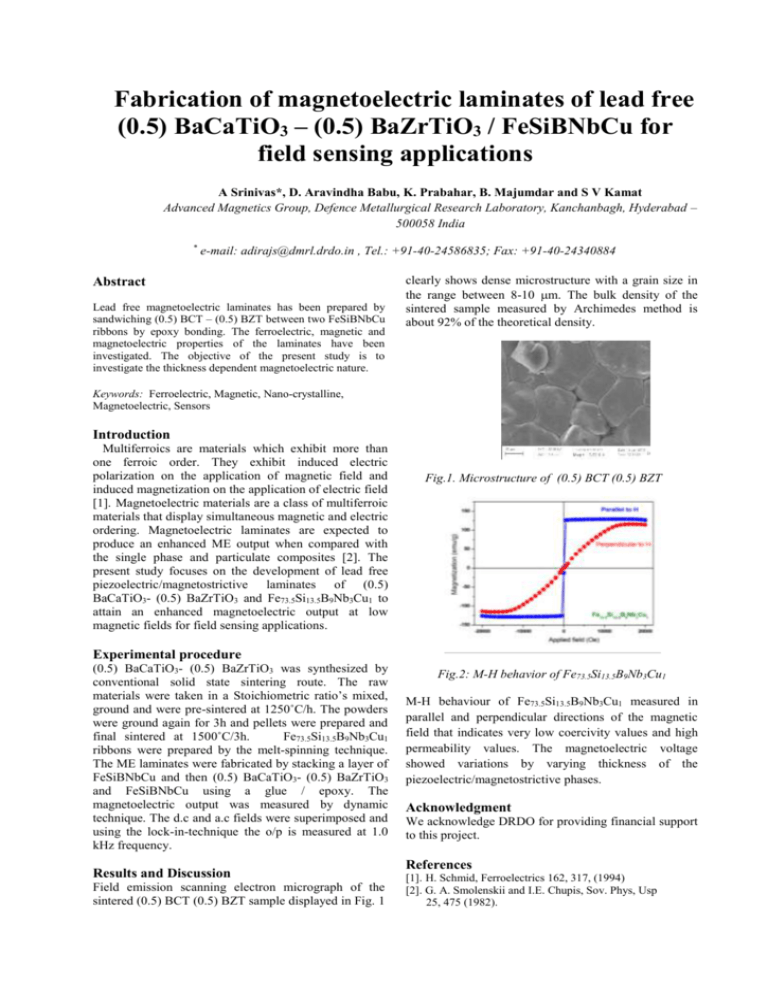

Fabrication of magnetoelectric laminates of lead free (0.5) BaCaTiO3 – (0.5) BaZrTiO3 / FeSiBNbCu for field sensing applications A Srinivas*, D. Aravindha Babu, K. Prabahar, B. Majumdar and S V Kamat Advanced Magnetics Group, Defence Metallurgical Research Laboratory, Kanchanbagh, Hyderabad – 500058 India * e-mail: adirajs@dmrl.drdo.in , Tel.: +91-40-24586835; Fax: +91-40-24340884 Abstract Lead free magnetoelectric laminates has been prepared by sandwiching (0.5) BCT – (0.5) BZT between two FeSiBNbCu ribbons by epoxy bonding. The ferroelectric, magnetic and magnetoelectric properties of the laminates have been investigated. The objective of the present study is to investigate the thickness dependent magnetoelectric nature. clearly shows dense microstructure with a grain size in the range between 8-10 m. The bulk density of the sintered sample measured by Archimedes method is about 92% of the theoretical density. Keywords: Ferroelectric, Magnetic, Nano-crystalline, Magnetoelectric, Sensors Introduction Multiferroics are materials which exhibit more than one ferroic order. They exhibit induced electric polarization on the application of magnetic field and induced magnetization on the application of electric field [1]. Magnetoelectric materials are a class of multiferroic materials that display simultaneous magnetic and electric ordering. Magnetoelectric laminates are expected to produce an enhanced ME output when compared with the single phase and particulate composites [2]. The present study focuses on the development of lead free piezoelectric/magnetostrictive laminates of (0.5) BaCaTiO3- (0.5) BaZrTiO3 and Fe73.5Si13.5B9Nb3Cu1 to attain an enhanced magnetoelectric output at low magnetic fields for field sensing applications. Fig.1. Microstructure of (0.5) BCT (0.5) BZT Experimental procedure (0.5) BaCaTiO3- (0.5) BaZrTiO3 was synthesized by conventional solid state sintering route. The raw materials were taken in a Stoichiometric ratio’s mixed, ground and were pre-sintered at 1250˚C/h. The powders were ground again for 3h and pellets were prepared and final sintered at 1500˚C/3h. Fe73.5Si13.5B9Nb3Cu1 ribbons were prepared by the melt-spinning technique. The ME laminates were fabricated by stacking a layer of FeSiBNbCu and then (0.5) BaCaTiO3- (0.5) BaZrTiO3 and FeSiBNbCu using a glue / epoxy. The magnetoelectric output was measured by dynamic technique. The d.c and a.c fields were superimposed and using the lock-in-technique the o/p is measured at 1.0 kHz frequency. Results and Discussion Field emission scanning electron micrograph of the sintered (0.5) BCT (0.5) BZT sample displayed in Fig. 1 Fig.2: M-H behavior of Fe73.5Si13.5B9Nb3Cu1 M-H behaviour of Fe73.5Si13.5B9Nb3Cu1 measured in parallel and perpendicular directions of the magnetic field that indicates very low coercivity values and high permeability values. The magnetoelectric voltage showed variations by varying thickness of the piezoelectric/magnetostrictive phases. Acknowledgment We acknowledge DRDO for providing financial support to this project. References [1]. H. Schmid, Ferroelectrics 162, 317, (1994) [2]. G. A. Smolenskii and I.E. Chupis, Sov. Phys, Usp 25, 475 (1982).