Baseboard Attachment

advertisement

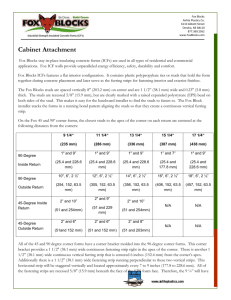

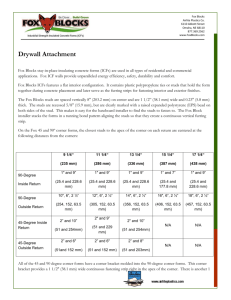

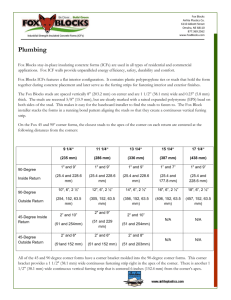

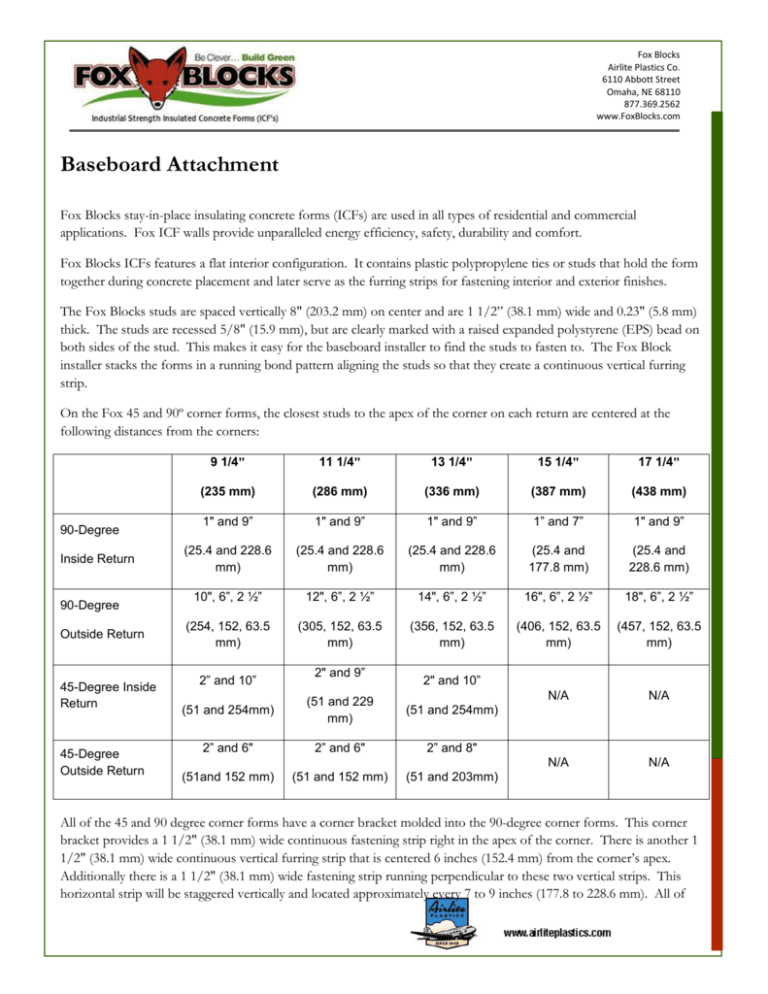

Fox Blocks Airlite Plastics Co. 6110 Abbott Street Omaha, NE 68110 877.369.2562 www.FoxBlocks.com Baseboard Attachment Fox Blocks stay-in-place insulating concrete forms (ICFs) are used in all types of residential and commercial applications. Fox ICF walls provide unparalleled energy efficiency, safety, durability and comfort. Fox Blocks ICFs features a flat interior configuration. It contains plastic polypropylene ties or studs that hold the form together during concrete placement and later serve as the furring strips for fastening interior and exterior finishes. The Fox Blocks studs are spaced vertically 8" (203.2 mm) on center and are 1 1/2” (38.1 mm) wide and 0.23" (5.8 mm) thick. The studs are recessed 5/8" (15.9 mm), but are clearly marked with a raised expanded polystyrene (EPS) bead on both sides of the stud. This makes it easy for the baseboard installer to find the studs to fasten to. The Fox Block installer stacks the forms in a running bond pattern aligning the studs so that they create a continuous vertical furring strip. On the Fox 45 and 90º corner forms, the closest studs to the apex of the corner on each return are centered at the following distances from the corners: 90-Degree Inside Return 90-Degree Outside Return 45-Degree Inside Return 45-Degree Outside Return 9 1/4" 11 1/4" 13 1/4" 15 1/4" 17 1/4" (235 mm) (286 mm) (336 mm) (387 mm) (438 mm) 1" and 9” 1" and 9” 1" and 9” 1” and 7” 1" and 9” (25.4 and 228.6 mm) (25.4 and 228.6 mm) (25.4 and 228.6 mm) (25.4 and 177.8 mm) (25.4 and 228.6 mm) 10", 6”, 2 ½” 12", 6”, 2 ½” 14", 6”, 2 ½” 16", 6”, 2 ½” 18", 6”, 2 ½” (254, 152, 63.5 mm) (305, 152, 63.5 mm) (356, 152, 63.5 mm) (406, 152, 63.5 mm) (457, 152, 63.5 mm) N/A N/A N/A N/A 2” and 10” 2" and 9” 2" and 10” (51 and 254mm) (51 and 229 mm) (51 and 254mm) 2” and 6" 2” and 6" 2” and 8" (51and 152 mm) (51 and 152 mm) (51 and 203mm) All of the 45 and 90 degree corner forms have a corner bracket molded into the 90-degree corner forms. This corner bracket provides a 1 1/2" (38.1 mm) wide continuous fastening strip right in the apex of the corner. There is another 1 1/2" (38.1 mm) wide continuous vertical furring strip that is centered 6 inches (152.4 mm) from the corner’s apex. Additionally there is a 1 1/2" (38.1 mm) wide fastening strip running perpendicular to these two vertical strips. This horizontal strip will be staggered vertically and located approximately every 7 to 9 inches (177.8 to 228.6 mm). All of Fox Blocks Airlite Plastics Co. 6110 Abbott Street Omaha, NE 68110 877.369.2562 www.FoxBlocks.com the fastening strips are recessed 5/8" (15.9 mm) beneath the face of the EPS foam face. Therefore, the 9 ¼” will have continuous fastening strips located 2 1/2 inches, 6 inches and 10 inches (63.5, 152.4, and 254 mm) from the outside corner, the 11 1/4" will have continuous vertical fastening located 2 ½” inch, 6 inches and 12 inches (63.5, 152.4. and 305 mm) from the outside corner, the 13 1/4" iForm will have a fastening strip located 2 ½” inch, 6 inches and 14 inches (63.5, 152.4. and 356 mm) from the outside corner, the 15 1/4” will have a fastening strip located 2 ½” inch, 6 inches, and 16 inches (63.5, 152.4, and 406.4 mm), and the 17 1/4” will have a fastening strip located 2 ½” inch, 6 inches, and 18 inches (63.5, 152.4. and 431.8 mm). 15-Minute Thermal Barrier Requirement. All model building codes require that the interior face of the foam insulated wall for all buildings be finished with an approved 15-minute thermal (fire) barrier, such as minimum ½" (12.7 mm) thick regular gypsum wallboard attached to the plastic studs. This requirement includes unfinished basement areas and some crawl spaces. Other building materials documenting the ASTM E-119 fire index rating of 15 would be acceptable. Attaching the Baseboard. There are two methods of attaching the baseboard to the Fox Blocks ICF walls. The method used is determined by the contractor, designer, and owner of the building based upon the specific project and the type of baseboard. The thickness and depth of the baseboard should be considered when choosing the proper baseboard attachment method. Method #1 After the drywall is installed, and using a pneumatic nailing gun and standard finishing nails, shoot the nail directly into the baseboard, through the drywall and into the Fox Blocks plastic furring strip or stud. The plastic stud can be found by: 1. Marking the floor before the drywall is installed 2. Following the drywall nailing pattern 3. Using a magnetic stud finder to find the location of the nails behind the drywall It is best to shoot the nail in at an angle toward the top and bottom side of the baseboard. Alternate the angles of the nails along the length of the baseboard. For additional connection strength, you can use compatible construction adhesive. Run a bead of construction adhesive along the back side of the baseboard prior to nailing it to the wall. If you do not want to use finishing nails, you can use finishing screws in the same way. The fasteners must be long enough to go through the thickness of the baseboard, the thickness of the drywall, the thickness of the EPS foam in front of the plastic stud and a minimum of 5/8” (12.7 mm) beyond the plastic stud. It is not necessary to butt two baseboards over the plastic ties. Fox Blocks walls have a solid continuous foam and concrete substrate behind the drywall. Be sure that the baseboard is tight against the wall when fastening the board to the wall. Method #2 This method involves fastening an OSB or plywood backing strip along the base of the wall. The thickness of the wood backing strip must be the same thickness as the drywall thickness to be used, and is installed prior to installing the Fox Blocks Airlite Plastics Co. 6110 Abbott Street Omaha, NE 68110 877.369.2562 www.FoxBlocks.com drywall. The height of the backing strip should be ½” (12.7 mm) lower than the baseboard material, and the drywall is then butted up to the top of the wood backing material. The wood backing is screwed directly to the plastic studs using sharp point course threaded #8 or #10 drywall screws. If desired, a compatible construction adhesive may be used on the back of the wood backing material to provide additional strength. After the backing strip is in place and the drywall is hung, the baseboard can then be fastened to the wood backing strip using a pneumatic nail gun with finish nails. Screws. Fox Blocks recommends using course thread drywall screws for fastening the wood backing to the Fox wall. The screws are fastened to the plastic studs molded into the forms. Fine thread screws do not have as much pullout strength as the course thread screws. When driving the screw into the plastic stud, bring it to snug tight and stop to prevent stripping out the plastic stud. Fox Blocks recommends using cordless drills instead of electric drills and keeping the cordless drill at its lowest power setting. Please follow the local building code jurisdiction regarding the fastener schedule. Adhesives. Some contractors may decide to use a combination of screws and adhesive when installing the baseboards. This method is acceptable as long as you are sure that the adhesives are compatible and approved for use on EPS foam materials. Petroleum or solvent-based products will deteriorate the foam.