Project Profile - Meat Products of India Ltd.

advertisement

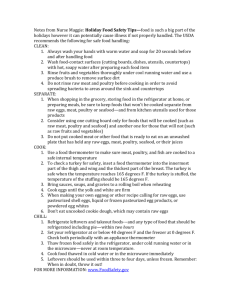

Expression of Interest Project Profile 1.1 Project Concept: The objective of Setting up a Hi-tech Poultry Meat Processing Facility at Mundayad, Kannur District, Kerala State is to make available hygienically slaughtered wholesome and safe meat to the population, with a thrust on humane slaughter methods. The project envisages the Design, Fabrication, Supply, Construction, Erection, Installation, Testing, Commissioning and demonstration of performance of Hitech Poultry Meat Processing Plant (1000 birds/ hour) including the units such as Rendering Plant, Effluent Treatment Plant, Biogas Plant including further processing , ancillary processing of by-products and all the other associated facilities at Mundayad, Kannur District, Kerala India. 1.2 Conformance to Standards: The Facility proposed to be provided shall conform to or shall be compliant with: a) Food safety &Standards Rules, 2011, Ministry of Health and family welfare, Government of India (GOI). b) FoodSafetyandStandardsAct,2006, Ministry of Law and Justice, GOI. c) Food safety and Standards Regulation, 2011, Ministry Of Health and Family welfare- GOI, Part-IV(see regulation 2.1.2(1) (5)- “Specific Hygienic and Sanitary practices to be followed by Food Business operators engaged in Manufacture, processing, storing and selling of Meat and Meat products” d) APEDA Procedure for Grant of Registration Certificate to Integrated Abattoirs & Meat processing Plants. e) APEDA Executive Manual-series Volume 2-Sanitary and Phyto-sanitary requirements in export oriented meat processing plants. f) APEDA Export of Raw Meat Chilled/Frozen (Quality Control and Inspection) Rules1992. g) CODEX Standards for Processed meat. h) The Contractor may also refer to: USDA/NCDA & CS Facility Guidelines for Meat processing Plants and those from the National Meat and Poultry Processing Board, GOI. i) All statutory requirements for building construction as laid down by local self governments in Kerala, Dept. of Factories & Boilers, Pollution Control Board, Electrical Inspectorate, Dept. Of legal Metrology etc 1.3 Project Description The Purchaser intents to setup Hi-tech Poultry Meat processing Facility for the production of wholesome poultry meat from chicken, with a capacity to handle 1000 birds per hour (8 hour single shift basis) including units such as Poultry Slaughtering Plant, Meat processing section, Rendering plant, Water treatment plant, Effluent treatment plant, Biogas plant and ancillary processing of by-products at Mundayad, Kannur. The work also includes provision of utilities such as steam, compressed air, water, Refrigeration systems and all electrical systems including standby Diesel Generators. The work involved consist of, but not limited to, conducting soil/site survey, site development including Landscaping, Roads and drainage system, including Storm water drainage, rain waster harvesting, preparation of detailed design and engineering drawings, civil/structural works, procurement/supply and installation of all material and equipments related to Architectural, Civil/Structural, Process, Rendering plant, Effluent Treatment Plant, Fire fighting works, Refrigeration System, Electricals, Instrumentation etc. followed by testing, trial run and commissioning of a new Hi-tech Poultry Processing Plant of capacity 1000 Birds per hour, for one shift operation per day. This shall also include 24 hours run of the water treatment unit, effluent treatment plant, blood processing facilities, biogas plant and solid waste rendering plant with required utilities followed by trial runs and commissioning and demonstration of performance of the units and entire Plant. Thereafter the successful contractor has to demonstrate continued performance of plant to the approved design and specifications for a period of 3 months from the date of commissioning. Subsequently, the contractor is responsible for the supervision of process, technical operation and total maintenance of the plant for a period of 12 months from the date of issue of Provisional Acceptance Certificate (PAC). This 12 month period will be construed as the defect liability period. During this period the Contractor shall also impart hands on training to Client’s technical personnel on the operation of the entire Plant and machinery including services, ETP, rendering plant etc. The technical specification given here under is only indicative and not descriptive and supplier shall ensure that the whole system supplied is complete in all respects for the smooth operation of the plant and should be suitable for the rated output. 1.4 Project Structure The project is envisaged to be developed on Turnkey basis. The project site (placed annexure 1) will be handed over to the successful bidder on “As is where is basis” for execution of the project. The relationship between MPI and the successful bidder is to be set as per the agreements which will be executed by and between MPI and the successful bidder. Period of completion: 12 months. 1.5 Responsibilities of the contractor a) Design and Engineering followed by maintenance of the project should be as per norms of Good Manufacturing Practice (GMP) and Good Industry Practice (GIP). The machinery and plant should be installed based on the HACCP principles/guidelines and its modifications time to time. The Contractor is required to put in place a documented Food safety Management System, mandating certification to Global Food Safety Initiative Schemes such as FSSC22000, SQF, BRC, IFS etc. Certification is to be obtained before commercial operation from reputed certifying agencies such as BVQ, DNV, BSI etc. b) Most energy efficient techniques should be adopted for plant operations, so that ultimately lowest energy and utilities consumption figures are obtained during normal plant operations. c) All industrial safety norms according to laid down guide lines of various State and central Government Departments are to be followed. d) The plant should be registered with FSSAI, APEDA and Ministry of Food Processing Industries, Govt. of India, under the Meat Food Products Order and Contractor has to obtain plant number. e) All equipments to be installed, including that for Services, should be of new and of latest Design and Specification. f) During the periods of project execution and defect liability period, successful bidder shall be entirely responsible for: i. ii. iii. iv. v. The implementation of the project as per the bid submitted and as per the detailed design/drawings prepared by him and approved by MPI/KITCO. Strict adherence to all of safety and quality standards at all facilities of the project at the time of construction as well as subsequent operation/maintenance of the facility during defects liability period. Imparting training to Client’s Technical & process personnel in Production processes, quality procedures, Standard Operating Procedures, Food Handling, Hygienic Practices, operation and maintenance of all Plants & machinery. During the above defects liability period, the Company shall replace/repair at MPI’s option any equipment, plant, machinery, structures etc., which may be found defective, malfunctioning etc. due to faulty design, faulty material of construction or poor workmanship, free of cost. The total maintenance cost of the proposed modern slaughter house, such as spares and consumables, for the above 1 year defect liability period is to be borne by the Contractor. 1.6 Basic project details and major equipments a) Capacity of the Hi-tech Poultry Meat Processing Plant must be minimum 1000 birds/Hour with provision for expansion in future . b) Motorized Bleeding Conveyor, Dressing Conveyor, Head & Offal Conveyor must be synchronized with PLC system to perform post-mortem procedure. c) All operation points must have separate platforms fitted with Wash Basin and Knife Sterilizer, with hot water facility. d) There should be separate Chutes for Leg, Head, Feather & Paunch materials. e) There should be procedure for identification of Chickens, including other parts of the bird. 1.7 General Features The Hi-tech Poultry processing Facility has to be established according to strict division of “clean” and “unclean” areas with separate entry for personnel. The project envisages segregating the unclean areas i.e. Poultry slaughtering, bleeding, de feathering, evisceration, Chicken washing& cleaning etc. and the clean areas where chilling, deboning, dispatches etc. take place. Visitors shall move from clean area to Dirty area only. The essential facilities required to be provided in the Abattoir are as follows: a. Adequate facilities for ante-mortem inspection. b. Carrying out humane slaughter by water Stunning, shackle, hang on bleeding rail, halal killing Stick and bleed in hanging position. c. Flaying, Dressing and Washing of the chicken. d. Hanging System for chicken and handling of edible offal’s. e. The conveyor motor speed to be synchronized for inspection of Chicken meat washing & cleaning, on-rail weighing, conveying them to the chiller, &de-boning stations, processing, packing, freezing & storage. f. Further processing such as sausages, breaded products, cutlets, patties etc. g. Chutes/conveyors for offal & viscera have to be provided. h. Proper handling of by-products. i. Inspection of Chicken Meat and disposal of Meat unfit for human consumption. j. Chillers, Blast freezers, Plate freezers and Cold room. 1.6 Tentative Process Flow Chart