file

advertisement

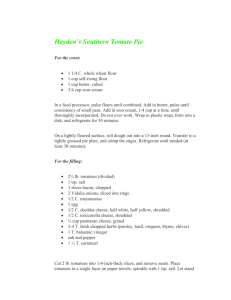

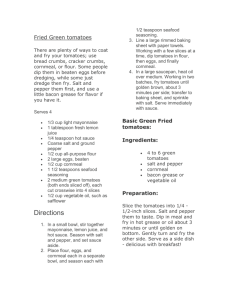

Increasing the Profitability of AgriTechnology's EverRipe Tomatoes Prepared for John Doe, Vice President AgriTechnology Loss of Profits for 2007 Although these tomatos is genetically engineered to remain ripe for longer periods of time, they're are more easily bruised than conventional tomatos. AgriTechnology reports indicate that 18.7 percent of this year's crop was unmarketable due to damage sustained during packageing and distribution. This resulted in an estimated loss for AgriTechnology of $1.2 million. We could increase the percentage of marketable fruit by reducing the number of times the fruit are handled and by decreasing storage time. Introduction This report presents our findings on how to improve the profitability of the EverRipe tomato crop. First, we describe how part of the crop was unmarketable due to losss during packaging and distribution. Then, we recommend improvments to the current packageing and distribution process that will reduce damage to future crops. Finally, we project costs for implementing these changes. Upgrading Packaging Plants Currently, the tomatoes are picked and shipped to nearby packageing plants where they’re hand-sorted, placed on a conveyer, and routed to the packaging machines. The following lists the upgrades: Packaged tomatoes put in corrugated cartons Sent to the loading area Cartons are stacked on pallets Loaded on trucks Shipped to produce warehouses By upgrading the packaging plants to include new "soft touch" technology which uses optical sensors to sort the tomatoes, we could reduce by one-half, the number of times the tomatoes are handled (Van Dyke 12-15). Improving Distribution Methods After the pallets are transported to the produce warehouses, they is stored in refrigerated rooms until the warehouses arrange with local trucking companies to ship the tomatos to buyers. We could eliminate lengty storage by building our own distribution centers near the packageing plants, purchasing our own shipping lines, and automateing our distribution system. By automating our distribution system, we could create a continuous-flow system where the tomatoes are shipped to our distribution centers, unloaded from inbound trucks, and moved across the dock to an outgoing distribution truck without having to be stored. Cost of the Improvements We estimate that these improvments would require a investment of approximately $7.2 million. Although this represents a major capital investment, the money would be recouped by an increase in marketable fruit. Competition among biotechnology companies is expected to increase dramatically in the next few years (Taylor and Smith 45-50); therefore, it is imperative that we implement these improvements to increase our profitability and remain competitive. Works Cited Van Dyke, Rita. "Application of Technology in Our Businesses and Institutions.” Industrial Summit Nov. 2007:12-15. Utilization of Optical Sensors. Optical Sensors Incorporated Service Guide and Report. 15 Jan. 2006. Taylor, Martha, and Mark P. Smith. Incorporating Optical Sensors in the Agricultural Industry. Lincoln: Midwest Press, 2007.