QUESTIONNAIRE FOR CLIMATIC POST

advertisement

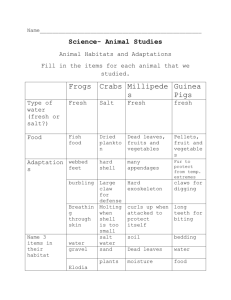

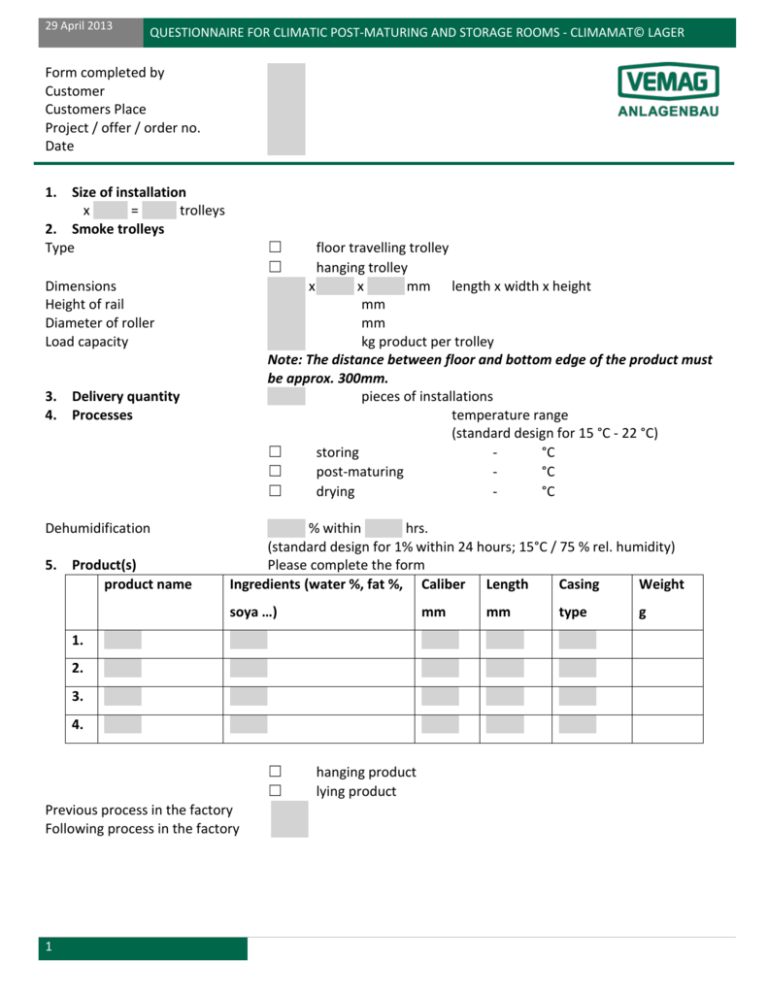

29 April 2013 QUESTIONNAIRE FOR CLIMATIC POST-MATURING AND STORAGE ROOMS - CLIMAMAT© LAGER Form completed by Customer Customers Place Project / offer / order no. Date 1. Size of installation x = trolleys 2. Smoke trolleys Type ☐ ☐ floor travelling trolley hanging trolley x x mm length x width x height mm mm kg product per trolley Note: The distance between floor and bottom edge of the product must be approx. 300mm. pieces of installations temperature range (standard design for 15 °C - 22 °C) ☐ storing °C ☐ post-maturing °C ☐ drying °C Dimensions Height of rail Diameter of roller Load capacity 3. 4. Delivery quantity Processes Dehumidification 5. Product(s) product name % within hrs. (standard design for 1% within 24 hours; 15°C / 75 % rel. humidity) Please complete the form Ingredients (water %, fat %, Caliber Length Casing Weight soya …) mm 1. 2. 3. 4. ☐ ☐ Previous process in the factory Following process in the factory 1 hanging product lying product mm type g 29 April 2013 6. QUESTIONNAIRE FOR CLIMATIC POST-MATURING AND STORAGE ROOMS - CLIMAMAT© LAGER Specification of equipment ☐ new investment ☐ replacement of existing equipment 7. Specification of new equipment Chamber ☐ ☐ Ductwork ☐ ☐ Machine unit ☐ ☐ ☐ Fresh air supply ☐ Heating Humidification Cooling system brick-built chamber (customer) wall elements (PU) (customer) ducts made of stainless steel hose system on top ☐ at rear wall left ☐ right within the room fresh air out of machine room (standard) m Length of fresh-air duct ☐ without filter ☐ with filter pad (G3) ☐ with coarse and micro filter (G4 and F7) ☐ overpressure louver ☐ exhaust air pipe m length ☐ steam (6 bar) ☐ steam (4 bar) ☐ steam (0,7 bar) ☐ electricity ☐ warm water °C inlet temperature °C return temperature ☐ steam (0,7 bar) ☐ water (two-component jet) Note: rel. humidity max. 80 %, not applicable for cooking processes ☐ Freon ☐ Ammonia ☐ Ethylene-Glycol concentration % ☐ Propylene-Glycol concentration % Note: Temperature of cooling media -4 °C Cold water supply Voltage 8. bar 3 Phase °C Frequence Accessories ☐ ☐ ☐ ☐ ☐ Over pressure louver exhaust air pipe (length 6 m) m other length fresh air from machine room, without filter fresh air filter-mat (G3) fresh air filter-system (G4 and F7) m Fresh air pipes, length 2 Hz 29 April 2013 QUESTIONNAIRE FOR CLIMATIC POST-MATURING AND STORAGE ROOMS - CLIMAMAT© LAGER Special requirements: ☐ ☐ ☐ ☐ ☐ ☐ ☐ 9. Assembly & start-up ☐ ☐ ☐ ☐ ☐ 10. Schedule Order Delivery Start-up Date, customer’s signature 3 water protection cap RFID Log-in barcode scanner Ethernet interface LDS (pcs.) systems has to be connected to LDS LDS already existing electric material ☐ only cables ☐ cable grate ☐ cableways length of electric material m Chief assembly Technical start-up VEMAG Assembly VEMAG Technological start-up VEMAG Electrical installation VEMAG week/year week/year week/year Date, VEMAG representative 29 April 2013 QUESTIONNAIRE FOR CLIMATIC POST-MATURING AND STORAGE ROOMS - CLIMAMAT© LAGER 11. Other Information Description of existing equipment 12. Switch Board / MICROMAT C7 Size ☐ Indication in ☐ Position of control display ☐ ☐ ☐ Position of control cabinet 13. Miscellaneous Decision criterion Additional information 4 ☐ ☐ ☐ 8 ̎ display (standard) °C left right on the door ☐ ☐ ☐ ☐ ☐ left right on the door ☐ ☐ ☐ 10 ̎ display °F front back side other position please define front back side other position