Effect of the physical state of lipids on shelf

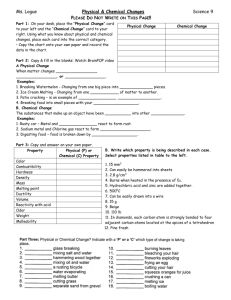

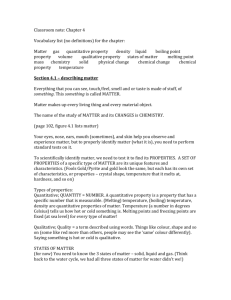

advertisement