Phase Domain

advertisement

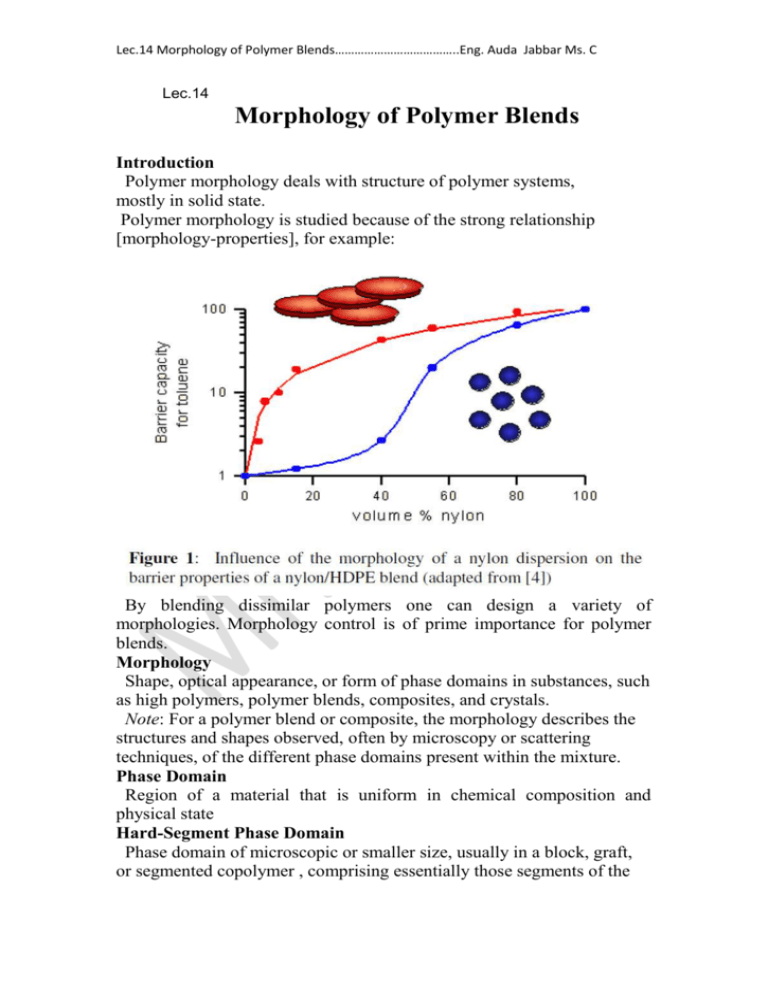

Lec.14 Morphology of Polymer Blends………………………………..Eng. Auda Jabbar Ms. C Lec.14 Morphology of Polymer Blends Introduction Polymer morphology deals with structure of polymer systems, mostly in solid state. Polymer morphology is studied because of the strong relationship [morphology-properties], for example: By blending dissimilar polymers one can design a variety of morphologies. Morphology control is of prime importance for polymer blends. Morphology Shape, optical appearance, or form of phase domains in substances, such as high polymers, polymer blends, composites, and crystals. Note: For a polymer blend or composite, the morphology describes the structures and shapes observed, often by microscopy or scattering techniques, of the different phase domains present within the mixture. Phase Domain Region of a material that is uniform in chemical composition and physical state Hard-Segment Phase Domain Phase domain of microscopic or smaller size, usually in a block, graft, or segmented copolymer , comprising essentially those segments of the Lec.14 Morphology of Polymer Blends………………………………..Eng. Auda Jabbar Ms. C polymer that are rigid and capable of forming strong intermolecular interactions. Note: Hard-segment phase domains are typically of 2–15 nm linear size. Soft-Segment Phase Domain Phase domain of microscopic or smaller size, usually in a block, graft, or segmented copolymer , comprising essentially those segments of the polymer that have glass transition temperatures lower than the temperature of use. Note: Soft-segment phase domains are often larger than hard-segment phase domains and are often continuous. Segmented Copolymer Copolymer containing phase domains of microscopic or smaller size, with the domains constituted principally of single types of structural unit. Note: The types of domain in a segmented copolymer usually comprise hard- and soft-segment phase domains. Continuous Phase Domain (Matrix phase domain) Phase domain consisting of a single phase in a heterogeneous mixture through which a continuous path to all phase domain boundaries may be drawn without crossing a phase domain boundary. Note: In a polymer blend, the continuous phase domain is sometimes referred to as the host polymer, bulk substance, or matrix. Discontinuous Phase Domain (discrete phase domain, dispersed phase domain) Phase domain in a phase-separated mixture that is surrounded by a continuous phase but isolated from all other similar phase domains within the mixture. Note: The discontinuous phase domain is sometimes referred to as the guest polymer. Lec.14 Morphology of Polymer Blends………………………………..Eng. Auda Jabbar Ms. C Dual Phase Domain Continuity( co-continuous phase domains) Topological condition, in a phase-separated, two-component mixture, in which a continuous path through either phase domain may be drawn to all phase domain boundaries without crossing any phase domain boundary. Core-Shell Morphology Two-phase domain morphology, of approximately spherical shape, comprising two polymers, each in separate phase domains, in which phase domains of one polymer completely encapsulate the phase domains of the other polymer. Note: This morphology is most commonly observed in copolymers or blends prepared in emulsion polymerization by the sequential addition and polymerization of two different monomer compositions. Cylindrical Morphology Phase domain morphology, usually comprising two polymers, each in separate phase domains, in which the phase domains of one polymer are of cylindrical shape. Notes: 1. Phase domains of the constituent polymers may alternate, which results in many cylindrical layers surrounding a central core domain. 2. Cylindrical morphologies can be observed, for example, in triblock copolymers. Fibrillar Morphology Morphology in which phase domains have shapes with one dimension much larger than the other two dimensions. Note: Fibrillar phase domains have the appearance of fibers. Lamellar Domain Morphology Morphology in which phase domains have shapes with two dimensions much larger than the third dimension. Note: Plate-like phase domains have the appearance of extended planes that are often oriented essentiallyparallel to one another. Microdomain Morphology Morphology consisting of phase microdomains. Nanodomain Morphology Morphology consisting of phase nanodomains. Onion Morphology Multiphase morphology of roughly spherical shape that comprises alternating layers of different polymers arranged concentrically, all layers being of similar thickness. Multicoat Morphology Morphology observed in a blend of a block copolymer with the homopolymer of one of the blocks and characterized by alternating concentric shells of the copolymer and the homopolymer. Lec.14 Morphology of Polymer Blends………………………………..Eng. Auda Jabbar Ms. C Note: The morphology is identical to onion morphology within a matrix of homopolymer Rod-Like Morphology Morphology characterized by cylindrical phase domains. Multiple Inclusion Morphology(salami-like morphology) Multiphase morphology in which dispersed phase domains of one polymer contain and completely encapsulate many phase domains of a second polymer that may have the same composition as the continuous phase domain . Methods of Polymer Morphology Microscopic Methods There is a broad spectrum of microscopic techniques available to observe polymer blend morphologies over several orders of magnitudes of length scale. It starts in the 10 μm range using optical microscopy (OM) and it goes down to the nm range using the high resolution transmission electron microscopy. 1. Optical Microscopy (OM) First information on the morphology of polymer blends is simply obtained by visual inspection. Blending two transparent, colorless amorphous polymers that have different refractive indexes usually leads to an opaque material, in which the size of phases exceeds the wavelength of visible light (>500 nm). It is Lec.14 Morphology of Polymer Blends………………………………..Eng. Auda Jabbar Ms. C usually assumed that to have opacity the difference of the refractive indexes should be larger than 0.003 . In the case when crystalline polymers are involved, the situation becomes more complicated. These polymers are frequently opaque because there are refractive index differences between the amorphous and crystalline regions and the supermolecular structures (spherulites) are also large (>500 nm), Thus in the case of blends with semicrystalline polymers, the distinction between homogeneous and heterogeneous structures of the amorphous phase by visual inspection is limited to studies above the melting point of the crystalline component. A more detailed insight into the phase morphology of polymer blends can be obtained by using optical microscopy (OM). The classical light microscopy is limited by diffraction to domains not smaller than 500 nm. In OM, the necessary contrast for detecting different phases might arise from a number of different sources such as color, opacity, refractive index, orientation, absorption or dichroic differences . There are numerous imaging methods of OM, e.g., transmissionreflection, bright field-dark field, phase contrast, interference microscopy, polarized light, etc. Lec.14 Morphology of Polymer Blends………………………………..Eng. Auda Jabbar Ms. C Lec.14 Morphology of Polymer Blends………………………………..Eng. Auda Jabbar Ms. C 2. Scanning Electron Microscopy (SEM) Scanning electron microscopy (SEM) is normally used to observe surfaces. The resolution is not so good as TEM. Usually, SEM micrographs are obtained by collecting secondary electrons emitted upon bombarding the samples with high energy electrons. This secondary electron image (SEI) gives information about the topography of the sample surface. To obtain an information of morphology in the bulk of the material, it is necessary to remove the surface layer. Only when adhesion between the phases is poor, "new surface", that reflects the bulk morphology can be created by fracturing the sample. Usually, to prevent plastic deformation, the sample is first annealed in liquid nitrogen, then fractured. Another method of removing the surface layer is by etching. This process may be carried out by: • Chemical etching, where one polymer is degraded using a chemical reaction and the reaction products can be removed from surface. • Solvent etching, to selectively dissolve one of the polymers. • Ion beam etching, to preferentially degrade one of the polymers. The low molecular weight byproducts evaporate under high vacuum. Lec.14 Morphology of Polymer Blends………………………………..Eng. Auda Jabbar Ms. C Lec.14 Morphology of Polymer Blends………………………………..Eng. Auda Jabbar Ms. C 3. Transmission Electron Microscopy (TEM) There has been a tremendous development in transmission electron microscopy (TEM) since its discovery by Ruska. To study the polymer morphology by TEM, a sample must be thin, usually thinner than about 200 nm. However, using field emission guns (FEG), thicker specimen (≤ 2 μm ) can be used. Since polymers are mainly composed of C, H, N and O atoms, the electron density difference between polymers is not large enough to achieve sufficient contrast in heterogeneous materials.Thus staining techniques are usually necessary. Table bellow gives an overview of the most common staining methods for polymers. Lec.14 Morphology of Polymer Blends………………………………..Eng. Auda Jabbar Ms. C For most cases staining with osmium or rhutenium tetroxide (OsO4 or RuO4, respectively) yields sufficient results. OsO4 reacts with isolated double bonds (C=O, C=C) such as the double bonds in polyisoprene and poly butadiene, but it does not react with conjugated double bonds. The mechanism of RuO4 staining seems to be different from OsO4. It does not react directly with chemical species, but rather it forms clusters. It stains most polymer but to a different degree dependent mostly on the diffusion rate. The diffusion of RuO4 into the polymer is most important. For crystalline polymers, RuO4 diffuses preferably into the amorphous regions and stains them, whereas the lamellar crystals remain unstained. The double staining technique facilitates a clear contrast for more complicated systems Lec.14 Morphology of Polymer Blends………………………………..Eng. Auda Jabbar Ms. C Figure : TEM micrograph of HIPS/ABS blend, double-stained with RuO4 and OsO4 Lec.14 Morphology of Polymer Blends………………………………..Eng. Auda Jabbar Ms. C Lec.14 Morphology of Polymer Blends………………………………..Eng. Auda Jabbar Ms. C Lec.14 Morphology of Polymer Blends………………………………..Eng. Auda Jabbar Ms. C Quantification of Morphology A microscopic image itself is important and useful.The quantification of morphology is often required, e.g., to establish processing conditionsmorphology and morphology-properties correspondences. Among the methods of morphology quantification, most powerful for polymer blends are digital image analysis (DIA) of micrographs and light scattering. 1. Image Processing Simple image processing devices are commercially available and are frequently used to obtain statistical parameters from the micrographs, such as number or volume average particle size, histogram for size distribution, and volume (area) fraction. 2. Light Scattering Light scattering provides several morphological parameters for polymer blends. While the number of parameters generated by light scattering parameters is limited (as compared to DIA),the method is faster and less expensive than electron microscopy followed by DIA. Light scattering provides a convenient and powerful way to generate routine data, e.g., during reactive processing of immiscible polymers. . Lec.14 Morphology of Polymer Blends………………………………..Eng. Auda Jabbar Ms. C