Final Exam - Bio-Link

advertisement

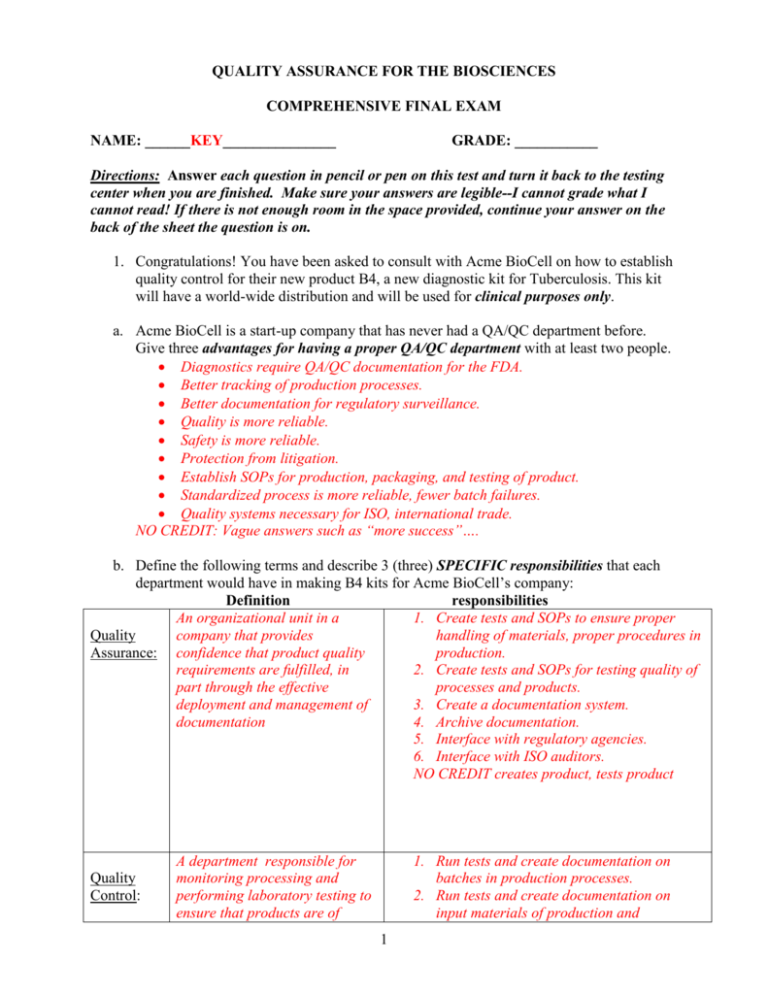

QUALITY ASSURANCE FOR THE BIOSCIENCES COMPREHENSIVE FINAL EXAM NAME: ______KEY_______________ GRADE: ___________ Directions: Answer each question in pencil or pen on this test and turn it back to the testing center when you are finished. Make sure your answers are legible--I cannot grade what I cannot read! If there is not enough room in the space provided, continue your answer on the back of the sheet the question is on. 1. Congratulations! You have been asked to consult with Acme BioCell on how to establish quality control for their new product B4, a new diagnostic kit for Tuberculosis. This kit will have a world-wide distribution and will be used for clinical purposes only. a. Acme BioCell is a start-up company that has never had a QA/QC department before. Give three advantages for having a proper QA/QC department with at least two people. Diagnostics require QA/QC documentation for the FDA. Better tracking of production processes. Better documentation for regulatory surveillance. Quality is more reliable. Safety is more reliable. Protection from litigation. Establish SOPs for production, packaging, and testing of product. Standardized process is more reliable, fewer batch failures. Quality systems necessary for ISO, international trade. NO CREDIT: Vague answers such as “more success”…. b. Define the following terms and describe 3 (three) SPECIFIC responsibilities that each department would have in making B4 kits for Acme BioCell’s company: Definition responsibilities An organizational unit in a 1. Create tests and SOPs to ensure proper Quality company that provides handling of materials, proper procedures in Assurance: confidence that product quality production. requirements are fulfilled, in 2. Create tests and SOPs for testing quality of part through the effective processes and products. deployment and management of 3. Create a documentation system. documentation 4. Archive documentation. 5. Interface with regulatory agencies. 6. Interface with ISO auditors. NO CREDIT creates product, tests product Quality Control: A department responsible for monitoring processing and performing laboratory testing to ensure that products are of 1. Run tests and create documentation on batches in production processes. 2. Run tests and create documentation on input materials of production and 1 suitable quality. packaging processes. 3. Calibrate equipment and test instruments. NO CREDIT Creates the tests or quality systems, Develops QA manuals, anything wrt QA c. Juran had a four-point fitness for use classification system outlined below. Give a SPECIFIC example of something that Acme BioCell should look at or do for each in each of these categories in order to produce a quality B4 kit product. Product must be shown to be an accurate and reliable diagnostic. 1) Quality of Design Product must have a niche in the market by offering better reliability, quicker assay, etc. (market research) Product must be robust, not prone to inactivation of reagents or incorrect usage. 2) Quality of conformance 3) Availability Product must meet the specifications set for the quality standard with a high degree of reliability. Product must meet standards of FDA. Components must be readily available. Production process must be robust, able to meet market demands. Product must have a sufficient shelf life to allow stockpiling in order to meet variable demands by the marketplace. A shipping process must be able to deliver product without compromising quality. Technical assistance for problems that arise in the customers’ use. 4) Field Service d. If you were contracted to perform a quality audit of Acme BioCell, what are 2 general things that you would be looking for? Justify your answer. 1. An adequate quality system has been designed. Check the SOPs, quality manuals. 2. The quality system is being followed. Check the documentation and records. 3. Employees are adequately trained. e. Give 5 examples of important documentation that Acme BioCell will maintain for cGMP compliance. List the department responsible for that documentation. 2 The documents that must be maintained include standard operating procedures, manufacturing and packaging records, component specifications, raw material specifications, analytical methods for testing raw materials and products, forms, and training records. A company must also have a change control system that requires assessment of any proposed changes and a system to retrieve and evaluate data for annual product reviews. Additional systems include those for corrective-preventative actions, and a system for supplier qualification. Within the testing laboratory, systems are required for the use and maintenance of reference standards, test solutions, volumetric solutions, and data retention. Ancillary systems may be necessary to monitor manufacturing that includes controlled substances and non-denatured and denatured alcohol for compliance with the Drug Enforcement Agency and the Alcohol and Tobacco Tax and Trade Bureau. 2. a. How does a company earn ISO 9000 certification? 1. Design and implement a quality system as outlined by ISO guidelines 2. The organization hires an outside firm to audit the quality system in place. A minimum of 3 months of evidence are required before this process can take place. 3. Once the system is audited, only minor non-conformities are allowed in order to obtain a certification. 4. Once the company is granted with a certification, periodic surveillance audits are agreed upon in order to maintain the “certified status”. b. Which departments and personnel must be prepared for an ISO 9000 audit? ALL departments, ALL personnel c. What are three key differences between ISO and GMP? GMP Mandatory system ISO Voluntary system Federal (US) Law International accepted standard, not law. Applies to pharmaceutical, biological, medical device manufacturing Can apply to any industry 3 Aim to ensure public safety by FDA oversight of food and medicinal manufacturing Aim to satisfy commercial or customer expectations of quality Standards are generic and broad in scope but apply to the pharma/medical industry only Standards are generic; they provide a blueprint for quality and can apply to any industy Standards rely heavily on testing and inspection; functional areas are clearly defined Standards rely on management commitment, systems and procedures (road map) and documentation; quality system needs to be only as comprehensive as necessary to meet quality objectives Compliance is monitored by FDA Compliance is monitored by outside auditors paid by the company 3. a. Describe two methods by which the FDA checks for compliance. 4pts 1. Inspection of production facilities. 2. Inspection of product in the marketplace. 1. 2. 3. 4. 5. 6. 7. 8. b. Describe five methods by which the FDA enforces its regulations, in the order of increasing harshness. 10pts + 2pts bonus correct order FDA 483: public notice of company’s noncompliance with GMPs; response is not required but recommended Requested Recall: requesting company’s voluntary recall of products in violation Warning Letter: gives a deadline for company to address the problem(s); public notice of FDA expectations for compliance Border Alert: prevents entry by US Customs License Suspension or Revocation: (licensing is required for biologics like vaccines, blood) Seizure: approved by US Federal Court judge; carried out by US Marshals Consent Decree: fines, reimbursements to the government for inspection costs, due dates for specific actions, penalties for noncompliance---usually permanent (25 in the last 13 years) Criminal prosecution: fines & prison time 4. Describe what is unique to the total quality management approach and explain how a total quality management approach can help to reduce an adversarial relationship between the labor force and the management of a company. 4pts Total Quality Management (TQM) is a customer-oriented quality improvement program focused on producing cost-effective quality products/services through effective coordination of all production processes by management personnel, and sincere involvement of all workers. Adoption of TQM creates a company culture that is harmonious and ensures complete cooperation between management and workers. The TQM approach states that every employee in the company is responsible for quality. One way to reduce an adversarial relationship is by motivating the employees. If any employee, from the janitor to the President, feels that his/her basic needs are of concern to the company, and that they are held in high esteem and recognized for their achievements, then they are willing to work hard and conscientiously for the company. Thus, a successful company finds ways to ensure the basic needs of all the employees are met. 4 5. What is the mission of MedWatch, and how do they accomplish their goals? 2pts MedWatch is the FDA safety information and adverse event-reporting program. It provides safety alerts for drugs, biologics, devices, and dietary supplements; safety-related drug labeling changes; and information about recalls, drug shortages, medication errors, etc. It also provides a mechanism for reporting adverse reactions and medical product problems to the FDA. 6. What do the following acronyms stand for, and describe their significance to a biotechnology company. 1pt + 2pt each = 3pts per = 30pts total Acrony Specifies Meaning and importance to a biotechnology company m Food & Drug Drugs, biologicals, medical devices, vet products, many foods sold FDA Administration interstate Office of mission: to ensure that FDA-regulated products comply with ORA Regulatory Affairs appropriate public health laws & regulations Responsibility: working with additional fed agencies on compliance & evaluating legal actions & directing criminal investigations in coordination with other agencies Form issued by Ability of FDA to enforce regulations to improve the quality of 483 FDA for lack of pharmaceutical products and protect the safety of the consumer compliance after an inspection Center for Drug Drugs-mission: to ensure that safe and effective prescription, nonCDER Evaluation & prescription, and generic drugs are available to the public as quickly as Research possible. Responsibility: 1. New drug development and review. (IND application for approval; clinical trials; NDA application) 2. Postmarket drug surveillance.(compliance with cGMPs, inspections of production facilities, drug labeling, reporting systems for adverse events) Center for Biologics: Biopharmaceuticals, vaccines. Mission: to regulate CBER Biologicals biological products including blood, vaccines, therapeutics, and related Evaluation & drugs & devices Responsibility: 1. monitoring pre-clinical and clinical Research testing of new biological products, and evaluate safety & effectiveness before marketing 2. Licensing biological products and manufacturing establishments 3. Compliance monitoring, lot releasing and postmarket surveillance. Current Good "Good manufacturing practice" or "GMP" is part of a quality system cGMP Manufacturing covering the manufacture and testing of pharmaceutical dosage forms Practice or drugs and active pharmaceutical ingredients, diagnostics, foods, pharmaceutical products, and medical devices. GMPs are guidance that outlines the aspects of production and testing that can impact the quality of a product. Environmental Regulates pesticides used in agriculture and substances released to the EPA Protection Agency environment. *GMO* National Institute The NIST is a non-regulatory federal agency within the U.S. Commerce NIST of Standards & Dept’s Technology Administration. To develop and promote Technology measurement, standards, and technology to enhance productivity, facilitate trade, and improve the quality of life. International ISO standards are developed by national delegations of experts from ISO Organization for business, government and other relevant organizations. Standardization 5 CFR The Code of Federal Regulations The CFR provides the information on quality systems in the laboratory (QSR), manufacturing practices, laboratory practices, and clinical practices. The CFR is a massive set of regulations, published annually. 7. A.What is a consent decree? 2pts A consent decree is a negotiated agreement between the FDA and a noncompliant manufacturer, that outlines steps that a company has to take in order to return to full, independent production. b. What prior action does the FDA take before a consent decree becomes necessary? 2pts The FDA implements a consent decree after the company has received repeated FDA 483s or warning letters concerning GMP observation and deficiencies, and these repeated offenses have not been corrected. c. What are 3 different types of negative effects that a consent decree can have on a pharmaceutical manufacturer? 3pts 1. The company may have to stop marketing a product 2. The company may have to stop selling a product 3. The company may have to hire an outside consultant to help bring them back into GMPs 4. Results in bad press for the company 5. Expensive to fix 8. Define the term audit and describe how it differs from an inspection or surveillance. 5pts An audit is an inspection of an organization’s adherence to the established quality standards and can be internal or external. Inspection is defined as a close examination of a process or product. Unlike inspections, audits do not necessarily identify the root cause of a problem, but ensure that areas within the company are following previously agreed upon process and standards. Surveillance is an inspection process using similar techniques as found in inspections and audits though less precise. Surveillance is a way to determine if the production process is performing as planned and if the product’s quality is acceptable 9. Describe how the 3 phases of clinical trials required by the FDA differ in goals and in size. Phase Experimental goals Size Designed to primarily test the safety of the proposed drug in 20-80 healthy I healthy humans. To see if there are any unexpected side effects volunteers and to establish the dosage levels that can be tolerated. In addition to evaluating the safety of the drug, its metabolic and pharmacologic properties in healthy humans are determined. Determine the drug’s efficacy. Patients who have the illness are 100-300 patients II treated with various dosages and are closely monitored for the with the illness effects of the drug. Double-blinded studies usually conducted at several hospital sites. 1000-3000 III These tests usually last for over three and a half years for most new patients drugs to establish its benefits and its long-term safety. At this point, the recommended dosages are determined, a risk versus benefit analysis is performed, drug interactions are explored, and other data are collected. 6 10. What are the three basic premises of ISO 9000 quality standards? Say what you do Do what you say Be able to prove it 11. Describe the differences in goals of the 3 parts of equipment validation: documents proof that the building, wiring, installation and Installation calibration of equipment, utilities, SOPs, spare parts, specifications, Qualification meets the design intention documents proof that the system (i.e. maintenance log review, raw and Operational process water systems, pure and process steam systems, process gases, Qualification HEPA challenge, autoclaves, vessels and blenders) performs as specified verify that facility, equipment or systems operate as intended under Performance challenge conditions Qualification 12. Describe three circumstances when a piece of equipment should be validated. When the equipment is installed. When the equipment is moved (within the same facilities or new facilities-any movement). In a typical biotechnology company bound by GMP or ISO9000 regulations, Equipment validation is part of the regular Quality Control procedures, usually performed on a committed time period (weekly, daily, or monthly). 13. What are the three federal regulatory agencies that are responsible for the evaluation of new crops developed using genetic engineering (GMOs)? Discuss their main concern (regulatory focus). FEDERAL REGULATORY FOCUS AGENCY Evaluates food and feed safety: The FDA’s Center for Food Safety and Nutrition (CFSAN) and the Center for Veterinary Medicine (CVM) evaluate new GM crops focusing on the FDA presence of increased or additional allergens, toxins, or a change in nutrition or composition. The main concern of the FDA is threats to human health through food and health of animals through feed. It’s important to note that FDA does not approve a product as safe, but rather completes a comparative evaluation of its unmodified counterpart. Ensures agricultural and environmental safety: The USDA through the Biotechnology Regulatory Service (BRS) office of the Animal and Plant Health Inspection Service (APHIS) regulates all GM crops prior to commercial release. The legislative authority for USDA USDA oversight comes from the Plant Protection Act of 2000. The main concern of the USDA is determining if the new plant will harm agriculture and the environment. Evaluates food safety and environmental issues associated with new pesticides: The EPA regulates GM crops that have altered pesticide characteristics. The main concern of the EPA EPA is the environmental and human health impacts of pesticides. 14. A testing method must have both precision and accuracy. Describe the following parameters of a testing method. The lowest concentration of the material of interest that the method can quantitate Limit of with acceptable accuracy and precision. This is particularly important when testing quantitation for impurities. The sensitivity of the assay used will determine the Limit of Quantitation. A measure of the extent to which a method can determine the presence of a Selectivity particular compound in a sample without interference from other materials present. 7 Linearity Range Robustness Percent error of the Mean Standard Deviation A very selective test will only give a positive result to the compound of interest The ability of a method to give test results that are directly proportional to the concentration of the material of interest within a given concentration range. Defined by the limits of concentrations, from the lowest to the highest, that a method can measure with acceptable results. A measure of the capacity of a method to remain unaffected when there are small, deliberate variations in method parameters. It provides an indication of the method’s reliability during normal use. Measures accuracy of data. Accuracy can be tested by using a reference standard which the true or expected value for the test is known. If it is a method being tested, the results are compared to a standardized assay. Accuracy relates to the quality of a result. Percent error of the mean (PEM)= (calculated mean – true value) x 100 true value Measures precision of data. Precision relates to the quality of the operation to obtain that result. BONUS QUESTION: This question must NOT be something already covered on exam. For full points it must be answered correctly. 8