SUPPLIER DEVELOPMENT ENGINEER/METALLURGIST

advertisement

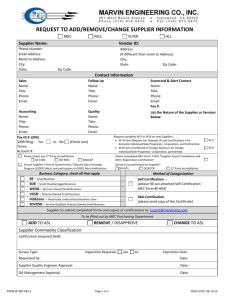

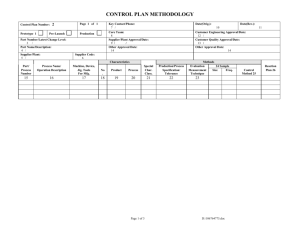

SUPPLIER DEVELOPMENT ENGINEER/METALLURGIST SPRINGFIELD, MO Are you ready for a new challenge where you can really make a difference? If you are a metallurgist or engineering professional who has worked with grey iron and ductile metals, this unique role may provide the visibility and opportunity you have been looking for! Our Client is a privately held, industrial equipment company that has been producing high quality products for over 100 years. Springfield, Missouri is the home of a $60 million, flagship division and manufacturing facility with a variety of CNC machines and metal working process, as well as coating and assembly operations. The quality driven, process-based culture encourages teamwork and the passionate pursuit of continuous improvement with tremendous opportunity for professional development and long term career satisfaction. Reporting to the Director of Strategic Sourcing/Supply Chain, this newly created role will develop and manage supplier relationships to ensure continuous improvement in quality standards. This important position will proactively identify, assess, and prioritize opportunities based on value and relevance; and initiate action plans to refine material standards and improve supplier conformance. Grey iron ductile, aluminum, bronze and stainless steel castings will be the primary focus, yet projects could target a range of supplier commodities including electric motors, switches and components, steel fabrications, machining, and mechanical seals. Specific responsibilities will include: Partner cross functionally with engineering, manufacturing, purchasing and quality to gain a broad understanding of the business and establish well defined goals. Strengthen supplier relationships with programs that use Lean Principles and Continuous Improvement tools while striving to be a value minded customer. Improve supplier quality and reduce scrap dollars by 25% year-over-year on current and new purchased materials. Develop and implement cost saving strategies and value enhancing alternatives that result in improved supplier quality. Ensure that adequate controls and visual management tools are in place for all areas of responsibility. Manage and/or participate in special projects to support the current needs and long term goals of the business. Seek opportunities to build skills and keep up to date on industry trends, new tools and methods, and best practices. The ideal candidate will have at least five years of experience in a CNC machining/manufacturing environment or metal casting foundry that includes work with grey iron and ductile castings. Strong business acumen combined with work experience that has included any combination of engineering, quality, supply chain, and/or purchasing responsibilities is required. Demonstrated success with Lean Principles and Continuous Improvement is also important. Educational credentials should include a Bachelor’s degree in Metallurgy, Engineering, Industrial Technology, Supply Chain, or other disciplines with relevant experience. MBA or Six Sigma Black Belt a plus. This is an independent role with the potential to make tremendous impact. Given the significant internal and external interaction, strong communications and interpersonal skills are essential. The right person will be strategic and forward thinking, with proven ability to identify problems, analyze issues, develop solutions, and accomplish goals. High sense of urgency, respect for others, attention to detail and unwavering integrity are all important attributes. Hanna Associates is a retained executive search firm working on an exclusive basis to manage the search process for Tuthill. All inquiries will be carefully considered and treated with complete confidentiality. Please submit resume to Patricia Hanna, Resumes@HannaAssociates.com.