bit25583-sup-0001-SuppData-S1

advertisement

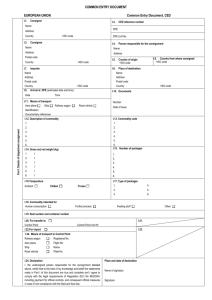

Supplementary Materials Title: Enhanced Production of Branched-Chain Fatty Acids by Replacing β-Ketoacyl-(acylcarrier-protein) Synthase III (FabH) Authors: Wen Jiang1§, Yanfang Jiang1§, Gayle J. Bentley2, Di Liu1, Yi Xiao1, Fuzhong Zhang1,2* 1 Department of Energy, Environmental and Chemical Engineering, 2Division of Biological & Biomedical Sciences, Washington University in St. Louis, Saint Louis, MO 63130, USA * Correspondence: Dr. Fuzhong Zhang Department of Energy, Environmental & Chemical Engineering, Washington University 1 Brookings Drive, St. Louis, MO, 63130, USA fzhang@seas.wustl.edu Tel: 314-935-7671 § These authors contributed equally to the work Supplementary Materials and Methods Plasmid construction Genes encoding S. aureus FabH (SaFabH) was codon-optimized for E. coli expression and synthesized by Integrated DNA Technologies (Coralville, IA, USA), whereas other genes were amplified by PCR using primers and templates listed in Supplementary Table 2. To create plasmids pSa-PecfabH-SafabH, pSa-PecfabH-BsfabH2, and pSa-PecfabH-BsfabH1, four fabH genes were separately cloned 3’ of the E. coli fabH promoter and assembled into the backbone of a BioBrick plasmid (Lee et al. 2011) pBbS7a-RFP using Golden-Gate DNA assembly method (Engler et al. 2008). To create plasmids pE8c-tesA-bkd and pB5c-tesA-bkd, an E. coli cytosolic thioesterase gene tesA (‘tesA; leader sequence deleted) (Steen et al. 2010) and a branched-chain α-keto acid dehydrogenase operon bkd from B. subtilis were amplified and inserted into either pBbB5c-RFP or pBbE8c-RFP (Lee et al. 2011) using restriction sites EcoRI/BamHI, BamHI/XhoI, and EcoRI/XhoI, respectively. Plasmid pB8c-tesA-bkd was created by transferring the pBBR1 replication origin from pBbB5c-RFP to plasmid pE8c-tesA-bkd using SacI and AvrII. Plasmids pE1k-BsfabH2, pB8k-BsfabH2, pB5c-bkd, pE8c-bkd, and pA5a-tesA were constructed by cloning target genes into the backbone of different BioBrick plasmids. To create plasmid pE2k-alsS-ilvCD and pE2k-leuABCD-alsS-ilvCD, the alsS-ilvCD fragment was PCR amplified from pSA69 (Atsumi et al. 2008), the leuABCD operon was PCR amplified from E. coli, and the corresponding fragments were then ligated with the backbone of pBbE2k-RFP using Gibson isothermal assembling method (Gibson et al. 2009). Composition of M9 MOPS Minimal Medium Minimal medium (M9 medium supplemented with 75 mM MOPS at pH 7.4, 2 mM MgSO4, 1 mg/L thiamine, 50 μg/mL lipoic acid, 10 μM FeSO4, 0.1 mM CaCl2 and micronutrients including 3 μM (NH4)6Mo7O24, 0.4 mM boric acid, 30 μM CoCl2, 15 μM CuSO4, 80 μM MnCl2, and 10 μM ZnSO4) containing 2% glucose as carbon source was used for cell growth and fatty acid production. For strains derived from CL111, 0.5% yeast extract was added for cell growth. qRT-PCR Strains DH1(ΔfadE), BC13, and BC13A were cultivated as described in section 2.3 and induced with 1 mM of IPTG and the supplementation of 1 g/L 4-methyl-2-oxopentanoic acid. Total RNAs were extracted from exponentially growing cells in duplicate using TRIzol Max Bacterial RNA Isolation Kit (life technologies). Contaminating DNA was removed with RNase-free DNase I (Thermo Scientific), and cDNAs were synthesized using a Revert Aid First Strand cDNA Synthesis Kit (Thermo Scientific) with random hexamer primers following the manufacturer’s protocol. The synthesized cDNAs were normalized to 0.2 μg/μL, and 1 μL was amplified using the Power SYBR Green PCR Master Mix (Applied Biosystems) and primers specific to the genes of interest (Supplementary Table 3) in a 20 μL reaction system. The reaction for each gene in each sample was performed in triplicates. qRT-PCR assays were carried out on an ABI7500 fast machine with the thermal cycling conditions recommended by the manufacturer. For data analysis, expression levels of the house keeping gene dnaK were used as a control for normalization between samples. Fold changes of genes of interest were calculated as 2-ΔΔCT. Quantification of free fatty acids For the quantification of free fatty acids, 1 mL of cell culture was acidified with 100 μL of concentrated HCl (12N). Free fatty acids were extracted twice with 0.5 mL ethyl acetate, which was spiked with 20 μg/mL of C19:0 fatty acid as an internal standard. The extracted fatty acids were methylated to fatty acid methyl esters (FAMEs) by adding 10 μL concentrated HCl, 90 μL methanol, and 120 μL of TMS-diazomethane, and incubated at room temperature for 15 min. FAMEs were quantified using a GC-MS (Hewlett-Packard model 7890A, Agilent Technologies) equipped with a 30 m DB5-MS column (J&W Scientific) and a mass spectrometer (5975C, Agilent Technologies) or a FID (Agilent Technologies) detector. For each sample, the column was equilibrated at 80 °C for 1 min, followed by a ramp to 280 °C at 30°C/min, and was then held at 280 °C for 3 min. Individual BCFA peaks were identified by comparing their retention time to those of standard BCFA methyl esters (Bacterial Acid Methyl Ester Mix, Sigma Aldrich) and by comparing their mass spectra to the Probability Based Matching (PBM) Mass Spectrometry Library. Concentrations of each fatty acid were determined by comparing the area of each FAME peak to a standard curve generated by standard FAME mixtures (GLC-20, GLC30, and Bacterial Acid Methyl Ester Mix, Sigma Aldrich) eluted using the same method. BCFA titer for each strain was measured in biological triplicate (starting from three different colonies) and average values are reported. Supplementary Table 1 Oligonucleotides used in this research Name Sequence SA1 TCAGCAGGTCTCAGTACATGAATGTAGGTATTAAAGGCTTCG SA2 TCTGGTCTCAATCCTTATTTA CCCCACTTAATGGTCATC BSA1 TCAGCAGGTCTCAGTACATGAAAGCTGGAATACTTGGTGTT BSA2 TCAGCAGGTCTCAATCCTTATCGGCCCCAGCGGA BSB1 TCAGCAGGTCTCAGTACATGTCAAAAGCAAAAATTACAGCTATC BSB2 TCAGCAGGTCTCAATCCTTACATCCCCCATTTAATAAGCA BKD1 TTTTTGGATCCAGACAGACAGGAGTGAGTCAC BKD2 TTTTTCTCGAGTTAGTAAACAGATGTCTTCTCGTC TES1 TTTTTTGAATTCAAAAGATCTAAAGGAGGCCATCCTATGGC TES2 TTTTTTCTCGAGAAAGGATCCTTATGAGTCATGATTTACTAAAGG PE1 TCAGCAGGTCTCACGTCAGCGTTGGCTACAAAAGAGAC PE2 TCAGCAGGTCTCAGTACGCTCAGTCACTTTTCGGTTA PSA1 TCAGCAGGTCTCAGGATCCAAACTCGAGTAAGGATC PSA2 TCAGCAGGTCTCAGACGTCAGGTGGCACTTTTC E2K1 GGATCCAAACTCGAGTAAG E2K2 ATGTATATCTCCTTCTTAAAAGATCTTTTG AI1 tttaagaaggagatatacatATGTTGACAAAAGCAACAAAAG AI2 actcgagtttggatccTTAACCCCCCAGTTTCGA AI3 ttatgaattaaAGATCTTTTAAGAAGGAGATATACATATG AI4 cgggttagAGATCTTTTAAGAAGGAGATATACATATG LEU1 tttaagaaggagatatacatATGAGCCAGCAAGTCATTATTTTC LEU2 cttaaaagatctTTAATTCATAAACGCAGGTTG Supplementary Table 2 Primers used for the construction of plasmids in this study Plasmid Primer 1 pSa-PecfabHBsfabH1 PSA1 pSa-PecfabHBsfabH2 PSA1 pSa-PecfabHSafabH PSA1 pB5c-tesAbkd/pE8ctesA-bkd pE2k-alsSilvCD Vector PCR Primer 2 Template PSA2 PSA2 PSA2 pE2kleuABCDalsS-ilvCD E2K1 E2K1 E2K2 E2K2 pE2k-alsSilvCD E2K1 E2K2 Primer 1 Primer 2 Insert PCR Template PE1 PE2 E. coli gDNA BSA1 BSA2 B. gDNA PE1 PE2 E. coli gDNA E. coli promoter BSB1 BSB2 B. gDNA B. subtilis fabH2 PE1 PE2 E. coli gDNA SA1 SA2 TES1 TES2 BKD1 BKD2 pBbE2kRFP pBbE2kRFP AI1 AI2 pSA69 B. subtilis alsS E. coli ilvC ilvD AI3 AI2 pE2k-alsSilvCD B. subtilis alsS E. coli ilvC ilvD pBbE2kRFP LEU1 LEU2 E. coli gDNA E. coli leuABCD pBbS7aRFP pBbS7aRFP pBbS7aRFP subtilis subtilis Chemical synthesis E. coli gDNA B. subtilis gDNA Gene of Interest E. coli fabH promoter B. subtilis fabH1 E. coli promoter fabH fabH S. aureus fabH E. coli tesA B. subtilis bkd Supplementary Table 3 Primers used for the qPCR in this study Gene Sequence fabD Forward: GGCCAGCTGAAGAACTGAATA Reverse: CATCATTGCCGGTGCTTTAC fabG Forward: GGCAAAGGTCTGATGTTGAATG Reverse: CCGGCATTATTGACCAGGATA dnaK Forward: AATCGAACTGTCTTCCGCTC Reverse: TCTTCAACCAGGCTTTCCAG Supplementary Table 4 Substrate specificity of four FabHs in this study Substrates EcFabH BsFabH1 BsFabH2 EcFabH SaFabH Acetyl-CoA 494 ± 11 14 ± 0.5 113 ± 10 50.5 ± 4.5 1.0 ± 0.1 2-methylpropanoyl-CoA <1 58 ± 2 149 ± 9 5.3 ± 0.8 31.4 ± 1.4 3-methylbutyryl-CoA <1 16 ± 0.8 162 ± 5 3.8 ± 0.2 14.9 ± 0.5 2-methylbutyryl-CoA <1 155 ± 10 79 ± 9 n.d. n.d. Reference (Choi et al. 2000) (Qiu et al. 2005) (A) 160 BC01 strain FFA Production (mg/L) 140 120 100 80 60 40 20 0 C12:0 C13:0 C14:0 C14:1 C14:0 C15:0 C15:0 C16:1 C16:0 C17:0 C18:1 C18:0 iso iso anteiso iso (B) 80 BC13A strain FFA Production (mg/L) 70 60 50 40 30 20 10 0 C12:0 C13:0 C13:0 C14:1 C14:0 C15:0 C15:0 C16:1 C16:0 C17:0 C18:1 C18:0 iso anteiso iso anteiso iso Supplementary Figure 1. Fatty acid production profiles of (A) strain BC01 (containing EcFabH& BsFabH2) and (B) the top-performing strain, BC13A (containing SaFabH), with the supplement of 1 g/L 4-methyl-2-oxopentanoic acid. (A) No Suppl. BCFA Production (mg/L) 16 3-methyl-2-oxobutyric acid 14 12 10 8 6 4 2 0 C13:0 iso C13:0 anteiso C14:0 iso C15:0 iso C15:0 anteiso C16:0 iso C17:0 iso C17:0 anteiso (B) No Suppl. BCFA Production (mg/L) 40 4-methyl-2-oxopentanoic acid 35 30 25 20 15 10 5 0 C13:0 iso C13:0 anteiso C14:0 iso C15:0 iso C15:0 anteiso C16:0 iso C17:0 iso C17:0 anteiso (C) No Suppl. 45 3-methyl-2-oxopentanoic acid BCFA Production (mg/L) 40 35 30 25 20 15 10 5 0 C13:0 iso C13:0 anteiso C14:0 iso C15:0 iso C15:0 anteiso C16:0 iso C17:0 iso C17:0 anteiso Supplementary Figure 2. Effect of α-keto acid supplementation to BCFA productions. Strain BC11A (containing BsFabH2) was cultivated as described in Methods and induced with 0.4% arabinose. At the moment of induction, cell cultures were supplemented with 1 g/L of either 3methyl-2-oxobutyric acid (A, solid columns), 4-methyl-2-oxopentanoic acid (B, solid columns), 3-methyl-2-oxopentanoic acid (C, solid columns), or nothing (A-C, empty columns). (A) No suppl. 3-methyl-2-oxobutyric acid BCFA Production (mg/L) 10 8 6 4 2 0 C13 iso C13 C14 iso C15 iso C15 C16 iso C17 iso C17 anteiso anteiso anteiso (B) No suppl. 4-methyl-2-oxopentanoic acid BCFA Production (mg/L) 20 16 12 8 4 0 C13 iso C13 C14 iso C15 iso C15 C16 iso C17 iso C17 anteiso anteiso anteiso (C) No suppl. 3-methyl-2-oxopentanoic acid BCFA Production (mg/L) 20 16 12 8 4 0 C13 iso C13 C14 iso C15 iso C15 C16 iso C17 iso C17 anteiso anteiso anteiso Supplementary Figure 3. Effect of α-keto acid supplementation to BCFA productions. Strain BC12A (containing BsFabH1) was cultivated as described in Methods and induced with 0.4% arabinose. At the moment of induction, cell cultures were supplemented with 1 g/L of either 3methyl-2-oxobutyric acid (A, solid columns), 4-methyl-2-oxopentanoic acid (B, solid columns), 3-methyl-2-oxopentanoic acid (C, solid columns), or nothing (A-C, empty columns). (A) Fatty Acid Production (mg/L) 37°C 30°C 25°C 100 80 60 40 20 0 (B) Fatty Acid Production (mg/L) without overlayer 90 75 60 45 30 15 0 with overlayer (C) 37°C 30°C 25°C 37°C with dodecane layer FFA Production (mg/L) 500 400 300 200 100 0 Total FFA Unsaturated FFA BCFA Supplementary Figure 4. Optimization of cultivation conditions. Effect of cultivation temperature (A) product trap (B) on BCFA production. Strain BC13A was induced with 0.1 mM of IPTG and supplemented with 1 g/L of 4-methyl-2-oxopentanoic acid at the moment of induction. (C) Total FFA, unsaturated FA, and BCFA titers of BC13A under different conditions. References Atsumi S, Hanai T, Liao JC. 2008. Non-fermentative pathways for synthesis of branched-chain higher alcohols as biofuels. Nature 451(7174):86-U13. Choi KH, Heath RJ, Rock CO. 2000. beta-ketoacyl-acyl carrier protein synthase III (FabH) is a determining factor in branched-chain fatty acid biosynthesis. Journal of Bacteriology 182(2):365-370. Engler C, Kandzia R, Marillonnet S. 2008. A one pot, one step, precision cloning method with high throughput capability. PLoS One 3(11):e3647. Gibson DG, Young L, Chuang RY, Venter JC, Hutchison CA, Smith HO. 2009. Enzymatic assembly of DNA molecules up to several hundred kilobases. Nature Methods 6(5):343U41. Lee TS, Krupa RA, Zhang F, Hajimorad M, Holtz WJ, Prasad N, Lee SK, Keasling JD. 2011. BglBrick vectors and datasheets: A synthetic biology platform for gene expression. J Biol Eng 5:12. Qiu XY, Choudhry AE, Janson CA, Grooms M, Daines RA, Lonsdale JT, Khandekar SS. 2005. Crystal structure and substrate specificity of the beta-ketoacyl-acyl carrier protein synthase III (FabH) from Staphylococcus aureus. Protein Science 14(8):2087-2094. Steen EJ, Kang YS, Bokinsky G, Hu ZH, Schirmer A, McClure A, del Cardayre SB, Keasling JD. 2010. Microbial production of fatty-acid-derived fuels and chemicals from plant biomass. Nature 463(7280):559-U182.